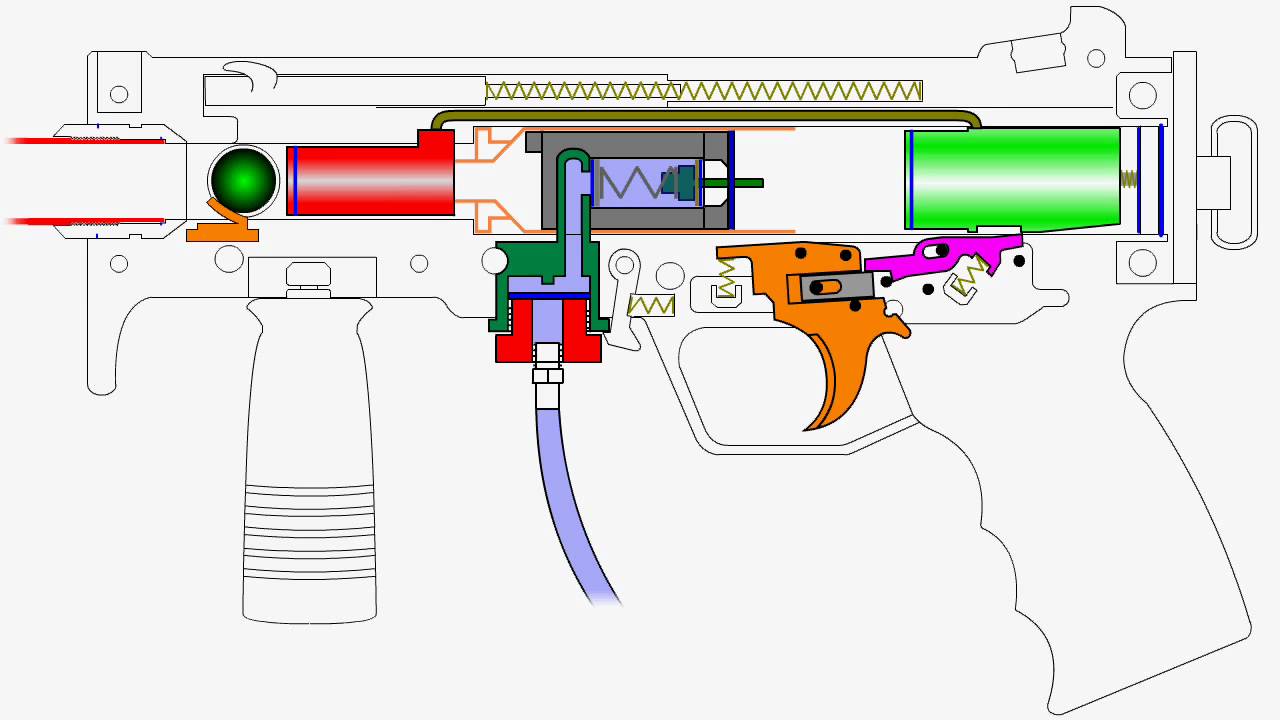

Semi-auto blowback WIP

Posted: Wed Aug 21, 2013 2:25 pm

I wanted t know if it's possible to use a hammer valve to archive by having the air re-cocking the hammer while firing a airsoft bb.

I studied some airsoft GBB guns, most of them follows the design of WA magna system

It's a simple system, but a large portion of the propellant is wasted. So I went for a different approach with a design that was attempted by numerous people but I haven't found one that made it work yet. Theory it's simple, having a hammer hit the valve opening it, the air fires the projectile while also pushes back the hammer, re-cocking it. In this design the air that's used to re-cock the hammer ends up exiting from the barrel as well so in theoretically no wast also easier to suppress. It's simpler for me to make the trigger but require a much more precise valve and hammer, also the pressure inside the chamber and various springs with correct length and strength.

I did several GGDT simulation to get an idea of hammer weight, travel distance (which also gives me the volume of air I needed to re-cock the hammer), hammer force (spring strength, weak enough for the air to push it, yet strong enough to open the valve to give the correct amount of air) and most important , barrel pressure. Then all left to do it's find the balance between force needed to open the valve, hammer strength and result barrel pressure.

In the worst case, considering dead volume as hammer travel*area, using a .2g 6mm bb (actually varies from 5.99 to 5.98 mm), 6.1mm barrel, the barrel pressure it's 1.6 bar, hope with a hop up (airtight detente) I may get a little more. So far with 1.6 bar should be enough.

For now I have finished all the tricky parts: trigger, valve and airtight hammer with spring.

I studied some airsoft GBB guns, most of them follows the design of WA magna system

It's a simple system, but a large portion of the propellant is wasted. So I went for a different approach with a design that was attempted by numerous people but I haven't found one that made it work yet. Theory it's simple, having a hammer hit the valve opening it, the air fires the projectile while also pushes back the hammer, re-cocking it. In this design the air that's used to re-cock the hammer ends up exiting from the barrel as well so in theoretically no wast also easier to suppress. It's simpler for me to make the trigger but require a much more precise valve and hammer, also the pressure inside the chamber and various springs with correct length and strength.

I did several GGDT simulation to get an idea of hammer weight, travel distance (which also gives me the volume of air I needed to re-cock the hammer), hammer force (spring strength, weak enough for the air to push it, yet strong enough to open the valve to give the correct amount of air) and most important , barrel pressure. Then all left to do it's find the balance between force needed to open the valve, hammer strength and result barrel pressure.

In the worst case, considering dead volume as hammer travel*area, using a .2g 6mm bb (actually varies from 5.99 to 5.98 mm), 6.1mm barrel, the barrel pressure it's 1.6 bar, hope with a hop up (airtight detente) I may get a little more. So far with 1.6 bar should be enough.

For now I have finished all the tricky parts: trigger, valve and airtight hammer with spring.