Page 1 of 2

Co Axial idea. *Update-Video*

Posted: Tue Jul 15, 2014 10:23 pm

by Teflon

Hiya spudders

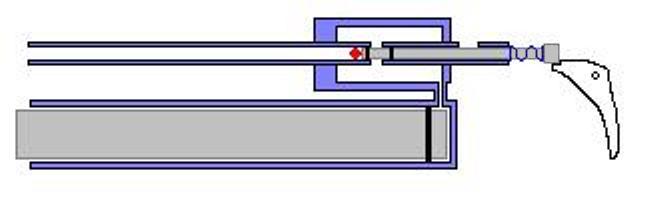

So i had an idea today for a coax pistol that has a single balanced spool valve that also acts as the loading bolt.

I attempted to design it as simple as possible, the bolt should snap all the way back to a stopper in the stock, allowing you to reload and push the bolt forward again.

- CoAx.JPG (13.81 KiB) Viewed 7196 times

Let me know what you think

Re: Co Axial idea.

Posted: Wed Jul 16, 2014 10:22 am

by jackssmirkingrevenge

That should work just fine, your pump needs a check valve though.

Re: Co Axial idea.

Posted: Wed Jul 16, 2014 10:33 am

by POLAND_SPUD

Me like it.

Re: Co Axial idea.

Posted: Wed Jul 16, 2014 10:41 am

by Teflon

The intended build will most likely be a single stroke, cause single stroke is the bomb, obviously the scale is quite off.

I also just wanted to mention that the gap in the barrel (at the point the spool valve seals) is 4 small holes in the tube, not just a gap.

Re: Co Axial idea.

Posted: Wed Jul 16, 2014 10:54 am

by POLAND_SPUD

It can be a gap just make sure the projectile won't fall through it

Re: Co Axial idea.

Posted: Wed Jul 16, 2014 11:01 am

by Technician1002

In larger sizes the gap can allow the front o-ring to expand and go over the end resulting in launching the projectile and ring. Been there and done that. If it is above 1 inch and over 60 PSI, you will want a ported design to keep the o-ring in place. Looks like a breech loading QDV to me.

Please be aware when fired, the pressur in the front of the valve pushes the projectile with the same force it pushes the valve. You will want something robust to prevent shooting the valve into spectators behind you.

I had a failure on my ABS cannon and launched the valve into my foot once.

If you want a faster valve, search the forums for QDV valves. Making the spool small, light and free to slide on the trigger rod will make them open with air pressure much faster than it could be opened by hand. Check the links in my SIG for more info.

What a high speed apple will do.

Re: Co Axial idea.

Posted: Wed Jul 16, 2014 2:04 pm

by wyz2285

Re: Co Axial idea.

Posted: Thu Jul 17, 2014 5:32 am

by jackssmirkingrevenge

Technician1002 wrote:Please be aware when fired, the pressur in the front of the valve pushes the projectile with the same force it pushes the valve. You will want something robust to prevent shooting the valve into spectators behind you.

I had a failure on my ABS cannon and launched the valve into my foot once.

Wise words,

a cautionary tale of a near miss I once had.

The intended build will most likely be a single stroke, cause single stroke is the bomb

Not if you're expecting much in the way of power... what are your performance goals for this project?

Re: Co Axial idea.

Posted: Thu Jul 17, 2014 7:11 am

by Teflon

JSR

For this particular project, a small pistol for my girlfriend to shoot bb's through paper targets with a cloth backstop.

I've all but finished it now, but its leaking

i had to epoxy 2 joints together to seal them because i didnt get the threading quite right

by the way...

http://www.pyramydair.com/blog/2008/07/ ... le-dragon/

I believe this is getting close to the practical limit of power from a single stroke pneumatic rifle.

ps.

Pictures will follow

Re: Co Axial idea.

Posted: Thu Jul 17, 2014 8:16 am

by jackssmirkingrevenge

Teflon wrote:JSR

For this particular project, a small pistol for my girlfriend to shoot bb's through paper targets with a cloth backstop.

In this case a single stroke should do... though you don't want your girlfriend getting used to single strokes

That's the example I mention every time:

http://www.spudfiles.com/pneumatic-cann ... er#p362287

http://www.spudfiles.com/pneumatic-cann ... er#p355117

http://www.spudfiles.com/offtopic-relat ... er#p274477

http://www.spudfiles.com/offtopic-relat ... er#p129039

Re: Co Axial idea.

Posted: Sun Jul 20, 2014 9:49 pm

by Teflon

Hi all

A quick picture of what I've got so far.

Please ignore; The poor lighting, the rubber-bands, the messy desk, and my crotch.

Ps. i completely forgot to allow extra room at the back for the breech.. so this model will either be a muzzle loader, or i just might make the extra effort to sleeve and extend the back, and make a new longer spool valve

Pss. it might not appear so in this photo, but their is adequate wood behind the spool to act as a backstop.

Psss. i also should note that the chamber volume is much smaller then it appears, i have 2 double o-ringed aluminium plugs, sealing each end of the chamber, their quite long and take up the majority of chamber that you can see.

Re: Co Axial idea.

Posted: Tue Jul 22, 2014 10:02 am

by jackssmirkingrevenge

That's looking pretty nifty! Will you be finishing the wood?

Re: Co Axial idea.

Posted: Tue Jul 22, 2014 7:15 pm

by Teflon

Indeed i will be finishing the wood, perhaps even replacing it with something a bit nicer then pine. although i definitely want to keep the weight as low as possible, its probably under 250g currently.

Im having issues with sealing so far, i mostly attribute this to incorrectly sized o-rings on the valve, the smallest ones i have are too big, so i sanded them down on the lathe... i figured i should have floating o-rings, so i tried them on but it leaked like a cholera patients butt hole. no idea why... ill try and get some better photos this evening.

Re: Co Axial idea.

Posted: Wed Jul 23, 2014 5:51 am

by jackssmirkingrevenge

Teflon wrote:i figured i should have floating o-rings, so i tried them on but it leaked like a cholera patients butt hole.

That was a mental image I could have done without

but yeah, getting the ideal size for o-rings is a pain. There are plenty of good reference guides to help you out though, here's one of them:

http://www.sealdynamics.com/o-ring-reference.pdf

Re: Co Axial idea.

Posted: Sun Jul 27, 2014 2:32 am

by Teflon

OK

So i managed to get it all sealing properly, found some suitable o-rings.

got it all cleaned up and shes shooting very nicely indeed, quite a bit more power then i had anticipated.

i sure as hell wouldn't want to be hit with this thing.

- trigger bit