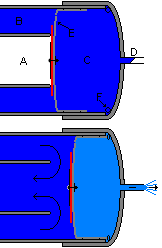

I watched a short video on building a piston valve where the professor made the piston out of hot glue sticks molded in a 2" pipe. He then glued a rubber gasket of sorts to it. It's spring loaded from the plug up against the 1" barrel. He then drilled two .5" holes in the cap -- one for the blow gun and one for a ball valve. This is all in a 2" T fitting. I understand how it seals off the barrel, but I don't understand how it actually fires. I get the idea of how it works from the diagram in the Wiki files, but his particularly doesn't sound like it will work because the mold of the 2" pipe won't seal on the inside diameter of the 2.375" T fitting. That leaves a .375" gap between mold and fitting. Here's the question: If the blow gun was opened to "release pressure behind the piston," will that be enough to pull the piston back to allow air to get into the barrel even with that gap?

Looking at the diagram in the Wiki files, how the heck is that built? Let's say it's a 1" barrel and a 2" chamber. That would be a 2" cap on the back, but what kind of cap (the piston) is on the inside of the chamber and how is it made to fit so perfectly?

Any answers to these questions would be very much appreciated. Thank you in advance.

-Jim