problem by designing shell ejection system

-

nitrogigi

- Private 2

- Posts: 33

- Joined: Thu Nov 15, 2012 7:27 am

- Location: france

- Been thanked: 3 times

Hi folks,

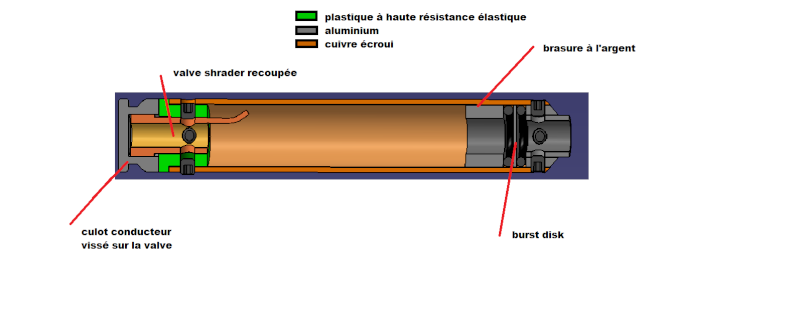

I'm actually designing an hybrid full automatic spudgun, where then chamber is a shell i've already designed, wich include ignition electrode, chamber, burst disk and the bullet (an airsoft aluminium BB)

my only problem is designing the extractor

does anyone already design a such thing?

I'm actually designing an hybrid full automatic spudgun, where then chamber is a shell i've already designed, wich include ignition electrode, chamber, burst disk and the bullet (an airsoft aluminium BB)

my only problem is designing the extractor

does anyone already design a such thing?

- jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

If you make a simple blowback mechanism, all the extractor needs to be is a point which the base of the cartridge strikes, which tips it out of the extraction port.

[youtube][/youtube]

[youtube][/youtube]

hectmarr wrote:You have to make many weapons, because this field is long and short life

- pneumaticcannons

- Specialist 3

- Posts: 392

- Joined: Sat Oct 30, 2010 9:45 am

- Location: shite country in asia

- Contact:

copy cat!!!: http://www.spudfiles.com/forums/semi-au ... 24507.html

jk

But seriously, you need to give us more details about your design. A diagram would help

In my design, I focused on keeping the rounds horizontal no matter what stage of the cycle it is in. It was a trade off with the ejection system complexity. Because I didn't want to deal with rounds chambering at all sorts of angles due to the physical size of the rounds and my facilities, I paid the price of a very complicated ejection mechanism. Although I have gotten the gun to successfully cycle single rounds consistently, If I could restart, and had adequate molding and/ or machining facilities, I would do away with the over-complicated ejection mechanism and replace it with a complicated inner geometry similar to that of a real firearm.

If your interested in my extractor, watch the video on the 9th post in the

linked thread. Simply a spring on the receiver end a magnet to pull the round the rest of the way.

Also check out some of JSR's work on blowback hybrids.

Edit: Crap, double ninja'd

jk

But seriously, you need to give us more details about your design. A diagram would help

In my design, I focused on keeping the rounds horizontal no matter what stage of the cycle it is in. It was a trade off with the ejection system complexity. Because I didn't want to deal with rounds chambering at all sorts of angles due to the physical size of the rounds and my facilities, I paid the price of a very complicated ejection mechanism. Although I have gotten the gun to successfully cycle single rounds consistently, If I could restart, and had adequate molding and/ or machining facilities, I would do away with the over-complicated ejection mechanism and replace it with a complicated inner geometry similar to that of a real firearm.

If your interested in my extractor, watch the video on the 9th post in the

linked thread. Simply a spring on the receiver end a magnet to pull the round the rest of the way.

Also check out some of JSR's work on blowback hybrids.

Edit: Crap, double ninja'd

ramicaza <- My Youtube Channel

- jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

That's quite a complex shell.

Have a read through my extensive efforts in the field: http://www.spudfiles.com/forums/hybrid- ... 19504.html

Have a read through my extensive efforts in the field: http://www.spudfiles.com/forums/hybrid- ... 19504.html

hectmarr wrote:You have to make many weapons, because this field is long and short life

-

nitrogigi

- Private 2

- Posts: 33

- Joined: Thu Nov 15, 2012 7:27 am

- Location: france

- Been thanked: 3 times

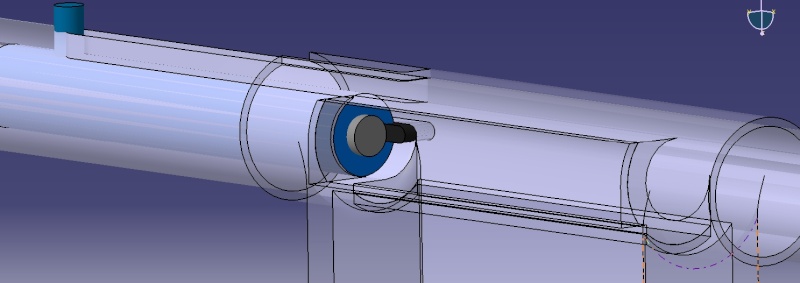

I like your cartridge, I like the system without burst disk, I think I'll keep the rear of my cartrige a bit modified, and take the front of your's, with a guiding cone to enter the barrel correctly, like on mine.

Let me do a bit of CATIA to arrange this

Let me do a bit of CATIA to arrange this

Firearms use a rim or channel in the base of the case, a spring loaded extractor claw rides in that groove, the extractor is in line with the ejection port. The exjector is just a small nub that the shell hits, and it's opposite to the ejection port.

If you have a bolt action rifle to hand, use it as an example.

If you have a bolt action rifle to hand, use it as an example.

/sarcasm, /hyperbole

-

nitrogigi

- Private 2

- Posts: 33

- Joined: Thu Nov 15, 2012 7:27 am

- Location: france

- Been thanked: 3 times

yeah, I know how it's made, but it's far to complicated to built on a spud gun, it's what I wanted to make first, but at the end I don't really need an extractor claw, though, I'll use a kind of blow-back

(I'm french, having a rifle to hand legaly is far harder for us)

(I'm french, having a rifle to hand legaly is far harder for us)

Let me tell you, it's really easy. You'll still need an ejector, but with well lubricated shells, you should be right. Use a good engine oil for lubrication.

And check out Weaponsguild.com, it's the Spudfiles of firearms.

And check out Weaponsguild.com, it's the Spudfiles of firearms.

/sarcasm, /hyperbole

-

nitrogigi

- Private 2

- Posts: 33

- Joined: Thu Nov 15, 2012 7:27 am

- Location: france

- Been thanked: 3 times

I'll better use silicone oil or such and a low flamable oil than motor oil, 'cause my calculations said the shell could be heaten to 300°C after a shot at mix 10, and I'm scared with such a heat and a bit of flame when it blows back, motor oil could inflame

I quench dull red steel in cheap used engine oil for case hardening, and I'm yet to have it do anything but smoke. Synthetic engine oil is perfect for your application.

I'll disassemble my .22 bolt for you later today, show you how simple it really is.

I'll disassemble my .22 bolt for you later today, show you how simple it really is.

/sarcasm, /hyperbole