high tech air cannon in progress

- Technician1002

- Captain

- Posts: 5189

- Joined: Sat Apr 04, 2009 11:10 am

The piston on the QDV can either be pulled open with a rope, rod, or blasted open by air pressure from the barrel. The video is this one. The piston rides on a rod, but is not directly connected to it.

http://www.youtube.com/watch?v=No3nI07mlQo

http://www.youtube.com/watch?v=No3nI07mlQo

- inonickname

- First Sergeant 4

- Posts: 2606

- Joined: Sun Dec 07, 2008 3:27 am

The QDV if constructed well in general will have more flow and a faster opening time. Depending on the piloting method used, both can allow very consistent shots.

PimpAssasinG wrote:no im strong but you are a fat gay mother sucker that gets raped by black man for fun

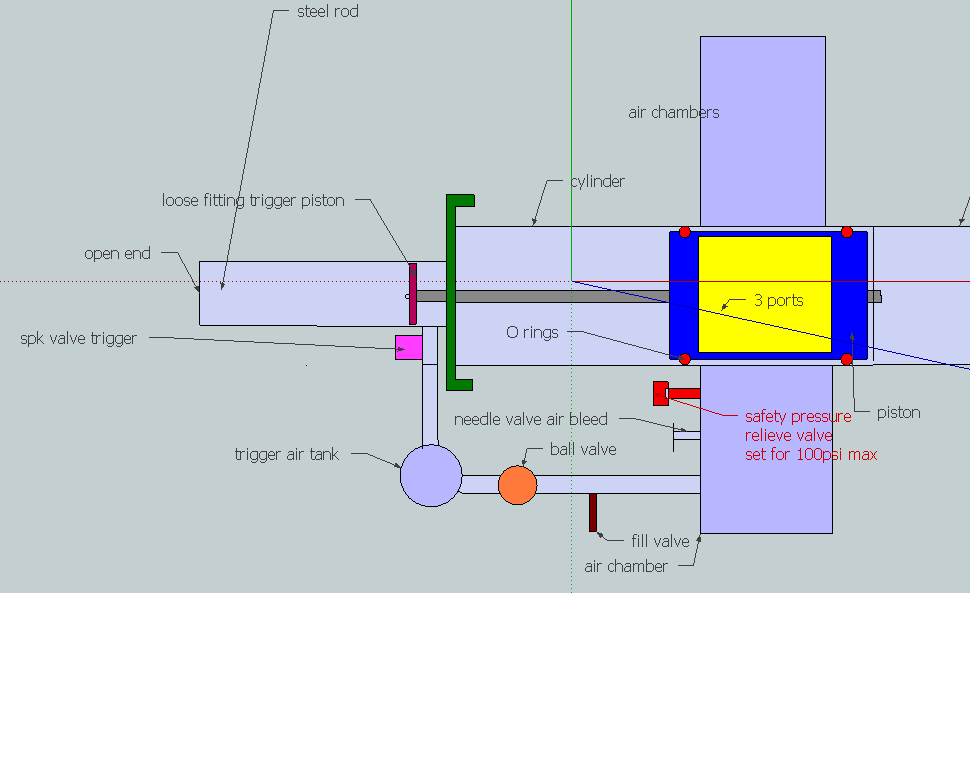

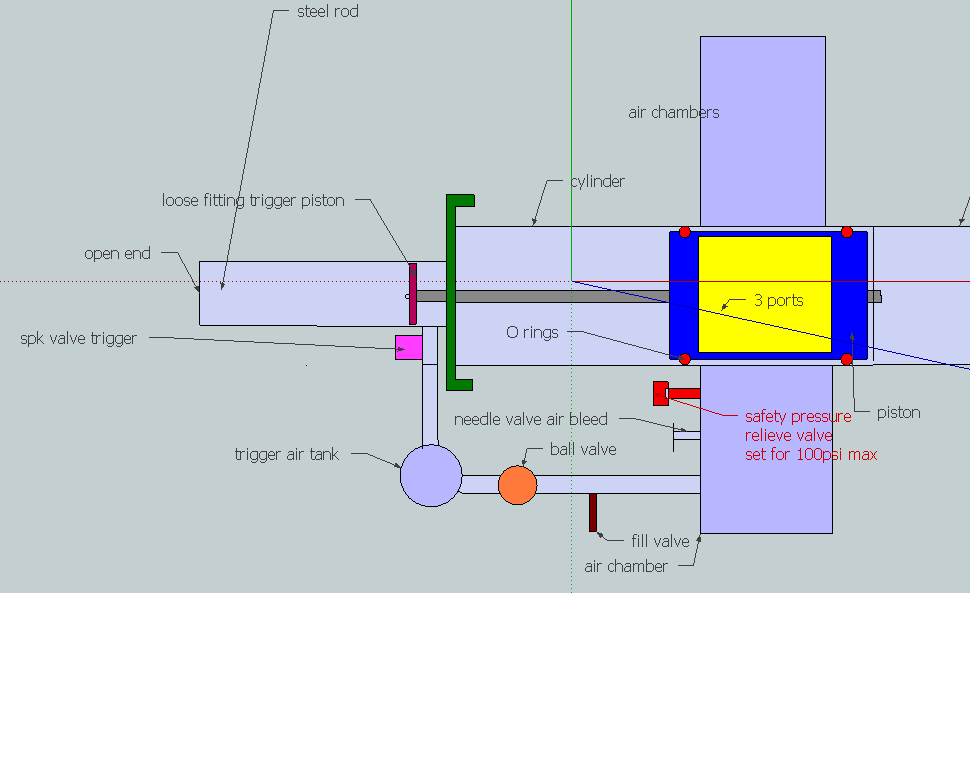

planning on building with a seperate air chamber as I posted drawing(see above) using a QDV actuacted by a spk valve triggered piston (back to back air cannons)

using this method will hopfully add to consienty and less operator error (jarring the barrell while pulling rod or rope) as well as opening the QDV at same speed.

Using two separate air chambers will prevent loss of projectiles propellant air being used for triggering.

received the transducer yesterday, planning on testing the transducer next week. Parts for chronograph and wind sensors have been ordered as well as the LCD modules. cannon project going on hold until I get my Christmas lights up. All 15,000 lights.

All computer operated to music.

Twisted Sister, Crazy Frog etc.

using this method will hopfully add to consienty and less operator error (jarring the barrell while pulling rod or rope) as well as opening the QDV at same speed.

Using two separate air chambers will prevent loss of projectiles propellant air being used for triggering.

received the transducer yesterday, planning on testing the transducer next week. Parts for chronograph and wind sensors have been ordered as well as the LCD modules. cannon project going on hold until I get my Christmas lights up. All 15,000 lights.

All computer operated to music.

Twisted Sister, Crazy Frog etc.

- spudtyrrant

- Corporal

- Posts: 550

- Joined: Fri Jan 02, 2009 6:10 pm

your better off to just build a good solid stand with an adjustable elevation level, considering your requirements aren't very demanding, i am able to easily land round within 5-10 feet of each other @ 100+ yards, and that's with a hand-held cannonMrDEB wrote:planning on building with a seperate air chamber as I posted drawing(see above) using a QDV actuacted by a spk valve triggered piston (back to back air cannons)

using this method will hopfully add to consienty and less operator error (jarring the barrell while pulling rod or rope) as well as opening the QDV at same speed.

I'm sure one with adjustable elevation and a secure stand would be even more effective

- Technician1002

- Captain

- Posts: 5189

- Joined: Sat Apr 04, 2009 11:10 am

You are a much better shot than I am. But then again I shoot from the hip. At 100 yards, I'm lucky to get them within 10 yards.spudtyrrant wrote:your better off to just build a good solid stand with an adjustable elevation level, considering your requirements aren't very demanding, i am able to easily land round within 5-10 feet of each other @ 100+ yards, and that's with a hand-held cannon

I'm sure one with adjustable elevation and a secure stand would be even more effective

yes a stand with elevation and mounted on an adjustable and lockable truant.

aim at target, adjust for wind, adjust air pressure using digital readout, then corrlating for muzzle velocity and BAM! hit on the target every time.

Or at least hope to.

aim at target, adjust for wind, adjust air pressure using digital readout, then corrlating for muzzle velocity and BAM! hit on the target every time.

Or at least hope to.

my latest additions

plan to use a small propane canister (used from camping) for trigger air tank. thinking why take away air from the main chambers for triggering. may not be consistent.

have an isolation ball valve so I can fill both chambers up but at say 10psi, close ball valve and continue filling main chambers.

transducer mounted to monitor main air chambers but with ball valve open I would be able to read pressure in both tanks. close ball vale upon reaching desired pressure for trigger.

going tomorrow to scrounge up some old propane tanks (5gal or 10gal) for main air chambers. cheaper that pvc pipe.

weld some 2 inch nipples then attach to QDV.

trigger tank to be hard plumbed as well. Have a needle valve to make minute adjustments to pressure as well as a safety valve to limit air chamber pressure to 100psi max.

QUESTION, should the propane tanks be full before welding on nipples --LOL [/img]

[/img]

plan to use a small propane canister (used from camping) for trigger air tank. thinking why take away air from the main chambers for triggering. may not be consistent.

have an isolation ball valve so I can fill both chambers up but at say 10psi, close ball valve and continue filling main chambers.

transducer mounted to monitor main air chambers but with ball valve open I would be able to read pressure in both tanks. close ball vale upon reaching desired pressure for trigger.

going tomorrow to scrounge up some old propane tanks (5gal or 10gal) for main air chambers. cheaper that pvc pipe.

weld some 2 inch nipples then attach to QDV.

trigger tank to be hard plumbed as well. Have a needle valve to make minute adjustments to pressure as well as a safety valve to limit air chamber pressure to 100psi max.

QUESTION, should the propane tanks be full before welding on nipples --LOL

[/img]

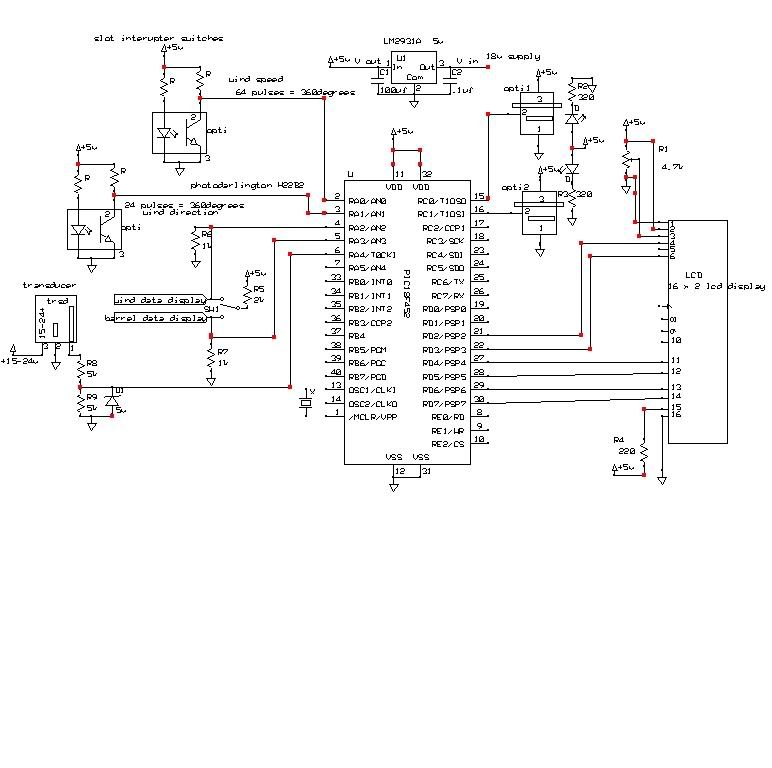

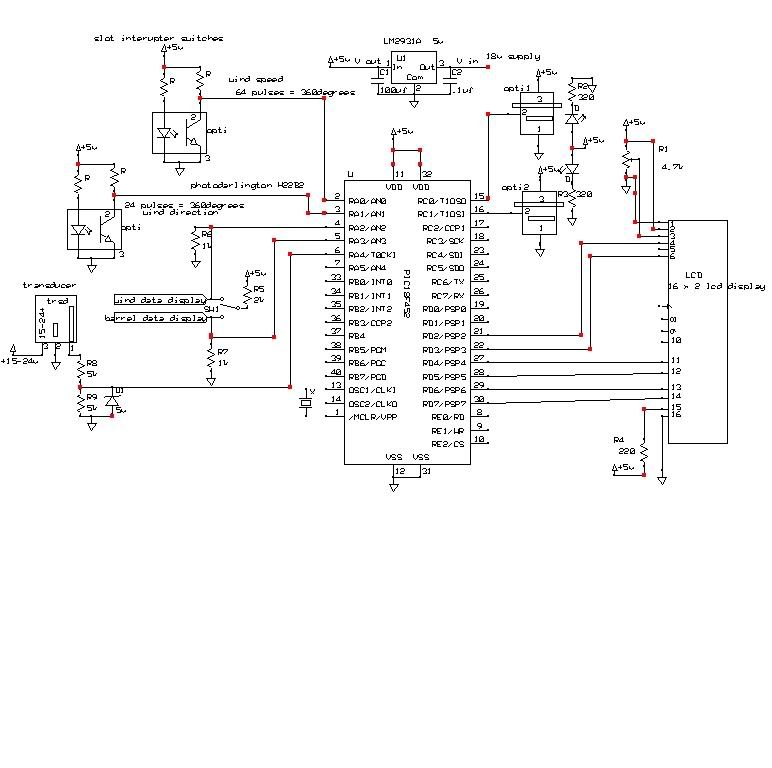

[/img]latest electronics schematic

need to tweek and write code.

test each segment seperatly -air pressure, wind speed, wind direction then muzzle velocity.

THEN combine the codes into one.

and yes if anyone is wanting to assist or when I get it done and you want to build same for code and/or printed circuit board and programed PIC chip.

but that may be several months down the road.[/img]

need to tweek and write code.

test each segment seperatly -air pressure, wind speed, wind direction then muzzle velocity.

THEN combine the codes into one.

and yes if anyone is wanting to assist or when I get it done and you want to build same for code and/or printed circuit board and programed PIC chip.

but that may be several months down the road.[/img]

- POLAND_SPUD

- Captain

- Posts: 5402

- Joined: Sat Oct 13, 2007 4:43 pm

- Been thanked: 1 time

sorry for mentioning it again but IMO you could build this gun from off the shelf parts

you could use 1/2" QEV (but 3/4" would be better) as the main valve

to get good consistency you could buy a solenoid spool/poppet valve off ebay for under 20$... but probably even a sprinkler valve would work just fine

ohh and I suppose that ~50 - 100 cm X 3/4" iron pipe would be enough

once you have all the parts and a couple of most common fittings you can build the gun in under 0.5 hour

I know you might think this is taking the easier rout... but hey is there anything wrong about it ?? if you can build it faster, easier and cheaper using off the shelf parts there is no point to complicate the design more than it's needed...

I am not saying you can't add electronics I am referring only to the gun itself... For me engineering is all about getting the best performance with as simple and cheap design you can find

that's just my 0.2$

you could use 1/2" QEV (but 3/4" would be better) as the main valve

to get good consistency you could buy a solenoid spool/poppet valve off ebay for under 20$... but probably even a sprinkler valve would work just fine

ohh and I suppose that ~50 - 100 cm X 3/4" iron pipe would be enough

once you have all the parts and a couple of most common fittings you can build the gun in under 0.5 hour

I know you might think this is taking the easier rout... but hey is there anything wrong about it ?? if you can build it faster, easier and cheaper using off the shelf parts there is no point to complicate the design more than it's needed...

I am not saying you can't add electronics I am referring only to the gun itself... For me engineering is all about getting the best performance with as simple and cheap design you can find

that's just my 0.2$

Children are the future

unless we stop them now

unless we stop them now

- Technician1002

- Captain

- Posts: 5189

- Joined: Sat Apr 04, 2009 11:10 am

They should be full of non combustible material. In my case I run an airline into it so it constantly gets an air purge to prevent the buildup of a combustible mixture. In my QDV's, I cut both ends of the tank for free air flow, preheat the area to be welded to drive off any oils and paint that can make an explosive mixture, then assemble with a copper air purge tube running, and then weld. Safety is no laughing matter, unless it happens to someone else.QUESTION, should the propane tanks be full before welding on nipples --LOL

In regards to your schematic, the weathervane input needs work. Use a couple more darlington pairs. There will need to be a Home flag so the North can be set every time and a second pickup on the optical encoder 90 degrees out of phase will provide up and down counts as the vane turns back and forth in the wind. Look up Sine/Cosine shaft encoders for more information.

To save pincount, a updown counter can be added to the 3 pickups so the count is reset as the home pulse is passed and the counter can then provide up/down counts to the pic from the home position in either direction. Callibration and startup only requires the vane to make one 360 rotation to start sending up/down counts to the PIC. The pic would then track position from the home position. This reduces the pincount to 2.

was concerned about North but thinking about it all I need is a reference position or HOME position to start for the direction setting.

have a 8-10f pole with weather stuff on top. lock the wind vane. then have aiming tube or sight , point at target from behind cannon with barrell pointed at targe as well.. lock the pole in this oreintation. unlock the vane then note which way the vane is pointing in relation to cannon position. the wind direction sensor will count how many degrees the vane has moved from HOME position. Think of a ps2 mouse wheel encoder, the old ball type mouse. only has two optic sensors per wheel..

wind sensor, just count/time rpm (drive car with unit out window. go say 20 mph then note reading. go 30 mph and note reading. then one can caculate rpm=mph of wind speed. sure simple math would work but maybe not as accurate?.

why use an up down counter when you have a PIC that will count up down for you? unless I am missng something.

as for cannon size? a 1 1/2inch QDV (shooting baseballs) with 2inch piping from old propane tanks.

thanks for ideas about airing out the tanks.. Plan was to remove the valve from top of tanks then inject air to purge any flammable gas from tank. Even fill with water to overflow then drain and air out. let dry a week outdoors with valve removed after airing out.

welding of tanks is a major concern but feel that removing the valve and purging as described should remove any gas from tank. I like your air purge idea but only welding one end of tanks with 2 inch nipples.

Has anybody used muffler pipe instead of galvanized pipe?

sounds like technician 1002 knows something about electronics?

have a 8-10f pole with weather stuff on top. lock the wind vane. then have aiming tube or sight , point at target from behind cannon with barrell pointed at targe as well.. lock the pole in this oreintation. unlock the vane then note which way the vane is pointing in relation to cannon position. the wind direction sensor will count how many degrees the vane has moved from HOME position. Think of a ps2 mouse wheel encoder, the old ball type mouse. only has two optic sensors per wheel..

wind sensor, just count/time rpm (drive car with unit out window. go say 20 mph then note reading. go 30 mph and note reading. then one can caculate rpm=mph of wind speed. sure simple math would work but maybe not as accurate?.

why use an up down counter when you have a PIC that will count up down for you? unless I am missng something.

as for cannon size? a 1 1/2inch QDV (shooting baseballs) with 2inch piping from old propane tanks.

thanks for ideas about airing out the tanks.. Plan was to remove the valve from top of tanks then inject air to purge any flammable gas from tank. Even fill with water to overflow then drain and air out. let dry a week outdoors with valve removed after airing out.

welding of tanks is a major concern but feel that removing the valve and purging as described should remove any gas from tank. I like your air purge idea but only welding one end of tanks with 2 inch nipples.

Has anybody used muffler pipe instead of galvanized pipe?

sounds like technician 1002 knows something about electronics?

- Technician1002

- Captain

- Posts: 5189

- Joined: Sat Apr 04, 2009 11:10 am

Yes, which way did it turn? You know how far in counts, but which way did it go? If it swings back a forth a few times, you get counts for another 90 degrees or so, but the PIC with a single pickup doesn't know the vane stopped and reversed direction a few times. You will need the second cosine pickup to acquire directional info. The schematic is missing the cosine pickup. 1 will be needed. For reliability in varying lighting conditions, consider using the stripped magnetic pattern on the back of refrigerator magnet business cards and a couple of hall sensors. They are unaffected by ambient light.MrDEB wrote:why use an up down counter when you have a PIC that will count up down for you? unless I am missng something.

A locked start up position will solve the home position issue instead of a flag.

You are welcome. Propane is heavier than air. Invert the tanks to let the heavy gas spill out. The tanks are unpainted inside so water will start rust. Painting after welding is recommended to reduce rust. The tanks may have oil residues inside. After purging welding may release combustible gass. Plan on purging during any welding to prevent build up of an explosive atmosphere. Another option is to drop in a few pounds of dry ice to purge out any Oxygen during welding.thanks for ideas about airing out the tanks.. Plan was to remove the valve from top of tanks then inject air to purge any flammable gas from tank. Even fill with water to overflow then drain and air out. let dry a week outdoors with valve removed after airing out.

welding of tanks is a major concern but feel that removing the valve and purging as described should remove any gas from tank. I like your air purge idea but only welding one end of tanks with 2 inch nipples.

ISCET certified journeyman technician.sounds like technician 1002 knows something about electronics?

- POLAND_SPUD

- Captain

- Posts: 5402

- Joined: Sat Oct 13, 2007 4:43 pm

- Been thanked: 1 time

let say that he must have got an orgasm when he saw your electronics schematicsounds like technician 1002 knows something about electronics?

Children are the future

unless we stop them now

unless we stop them now