Tip on discarding sabot for APFSDS round?

- SpudFarm

- First Sergeant 3

- Posts: 2571

- Joined: Sat Nov 04, 2006 9:39 am

- Location: Norway Trondheim area

First off, a big thanks to the last two posters. You wrote very informative posts although I cant seem to agree with iknowmy3tables. If a projectile like this yaw sideways in those speeds I am achieving it will cause MASSIVE drag at the fins.

My sabot design worked absolutely flawlessly. The sabot was laying about 3m from the muzzle after the shot. The penetrator worked even better then expected.

Imagine the force needed to tear of those fins.

I think the video will speak for itself because I am speechless right now. A spudgun penetrating so much wood and then moving a 3kg rock out of the way and penetrating to deeply to dig after it into a rocky gravelpit? Simply AMAZING, it finally showed some power.

Watch it in HD and full screen and look at the impact in the ground. Might not be finished processing yet though.

My sabot design worked absolutely flawlessly. The sabot was laying about 3m from the muzzle after the shot. The penetrator worked even better then expected.

Imagine the force needed to tear of those fins.

I think the video will speak for itself because I am speechless right now. A spudgun penetrating so much wood and then moving a 3kg rock out of the way and penetrating to deeply to dig after it into a rocky gravelpit? Simply AMAZING, it finally showed some power.

Watch it in HD and full screen and look at the impact in the ground. Might not be finished processing yet though.

"Made in France"

- A spud gun insurance.

- A spud gun insurance.

- jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

Beautiful, nice to see a properly engineered projectile and cannon come together  how about some steel plate next?

how about some steel plate next?

hectmarr wrote:You have to make many weapons, because this field is long and short life

- SpudFarm

- First Sergeant 3

- Posts: 2571

- Joined: Sat Nov 04, 2006 9:39 am

- Location: Norway Trondheim area

Thank you jack!jackssmirkingrevenge wrote:Beautiful, nice to see a properly engineered projectile and cannon come togetherhow about some steel plate next?

I certainly want to shoot at something like a 1" steel plate but the lack of portability means I have to fire in my yard. And I guess you have seen what happened last time I fired at a plate?

I am working on making it more portable though.

"Made in France"

- A spud gun insurance.

- A spud gun insurance.

- jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

I remember thatSpudFarm wrote:And I guess you have seen what happened last time I fired at a plate?

hectmarr wrote:You have to make many weapons, because this field is long and short life

- SpudFarm

- First Sergeant 3

- Posts: 2571

- Joined: Sat Nov 04, 2006 9:39 am

- Location: Norway Trondheim area

Haha, I am a bit ashamed of that.jackssmirkingrevenge wrote: I remember thatsafety first of course.

A idea might be building a small shed in the woods with a hole in the wall where I can stick the barrel out and fire from inside. Then I only have to cut disks to fire and not assemble the whole gun.

Although small shed might not be the word when talking about housing a 6.5m cannon..

"Made in France"

- A spud gun insurance.

- A spud gun insurance.

-

iknowmy3tables

- Staff Sergeant

- Posts: 1596

- Joined: Fri Dec 15, 2006 3:57 pm

- Location: maryland

- Has thanked: 3 times

- Been thanked: 9 times

awesome video, I see so you used a combination of epoxy and foam disks

if you plan on shooting that steel plate again I'd recommend clamping a sheet of plywood in front of it to prevent deflection, it might reduce penetration but seeing the damage your gun can do it shouldn't be much

good point, but the yaw you ought to be concerned about is with impact on targets very similar to how some military munitions yaw on/in targets to create larger wounds. It'll be more likely to yaw and deflect with impact on a harder target.If a projectile like this yaw sideways in those speeds I am achieving it will cause MASSIVE drag at the fins.

if you plan on shooting that steel plate again I'd recommend clamping a sheet of plywood in front of it to prevent deflection, it might reduce penetration but seeing the damage your gun can do it shouldn't be much

- jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

...or how about a softer metal cap...iknowmy3tables wrote:if you plan on shooting that steel plate again I'd recommend clamping a sheet of plywood in front of it to prevent deflection, it might reduce penetration but seeing the damage your gun can do it shouldn't be much

hectmarr wrote:You have to make many weapons, because this field is long and short life

-

iknowmy3tables

- Staff Sergeant

- Posts: 1596

- Joined: Fri Dec 15, 2006 3:57 pm

- Location: maryland

- Has thanked: 3 times

- Been thanked: 9 times

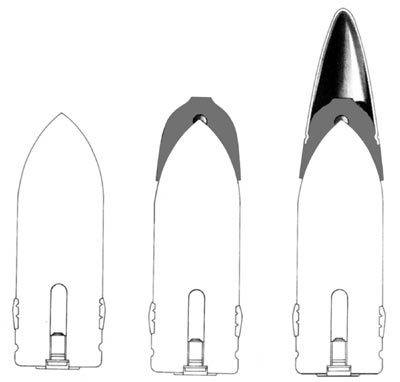

Thats for spin stabilized projectiles to maintain aerodynamic Spitzer shape, but for a fin stabilized dart the change in the center of mass would be insignificant as the mass is already spread out in a elongated shape.

- SpudFarm

- First Sergeant 3

- Posts: 2571

- Joined: Sat Nov 04, 2006 9:39 am

- Location: Norway Trondheim area

iknowmy3tables wrote:awesome video, I see so you used a combination of epoxy and foam disksIf a projectile like this yaw sideways in those speeds I am achieving it will cause MASSIVE drag at the fins.

good point, but the yaw you ought to be concerned about is with impact on targets very similar to how some military munitions yaw on/in targets to create larger wounds. It'll be more likely to yaw and deflect with impact on a harder target.

if you plan on shooting that steel plate again I'd recommend clamping a sheet of plywood in front of it to prevent deflection, it might reduce penetration but seeing the damage your gun can do it shouldn't be much

The stuff you see in front of the projectile while it is in the pipe is about 40g of grease to prevent the sabot from melting. I might use epoxy to glue the disks together when I am filming it at high speed to get one awesome video.

And if I am going to shoot at a plate I will attach a big pipe to the plate (probably weld or bolts) and then have a 1" wood plate in the other end. The projectile will pass through the wood easily I hope and hit the plate. If it deflects it will be stopped or loose alot of energy on impact with the wood.

I see no point in engineering a APFSDS design if you are going to make the target penetrateable and not improving upon the projectile instead.

I would like if Ragnarok could come up with some tips for me. Both on the projectile itself and the ricochet preventor. He has alot of knowledge in those things.

Thanks.

"Made in France"

- A spud gun insurance.

- A spud gun insurance.

- jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

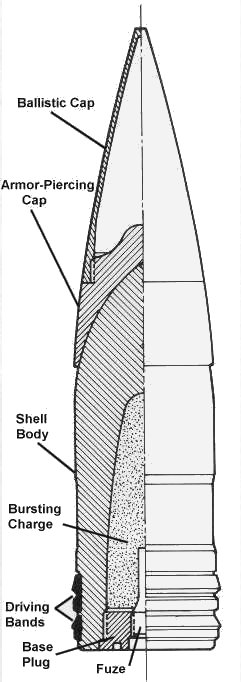

The "ballistic cap", yes, but as to the "armour piercing cap", it is there to "lubricate" the passage of the shell through armour:iknowmy3tables wrote:Thats for spin stabilized projectiles to maintain aerodynamic Spitzer shape

hectmarr wrote:You have to make many weapons, because this field is long and short life

- SpudFarm

- First Sergeant 3

- Posts: 2571

- Joined: Sat Nov 04, 2006 9:39 am

- Location: Norway Trondheim area

Since I already have a topic on Projectile related discussion I thought I could post this here.

I just made some slugs that I would like your opinion on. Not made to be pretty but functional.

The one to the left is a steel cored simple slug housed in a 32mm steel pipe.

The one to the right is a hollow point that I am going to fire at clay.

The question is if you think it will hit with its nose first or if I have to use a longer pipe at the back and/or flange it to make it have more drag.

It will be fired into 20kg of clay at a range of 20-30meters. Probably going to load to 7x since they are 375g each.

What I am looking for is even expansion of the slug at the moment of impact.

Just tell me what you think. I hate putting work into projectiles that are utterly useless.

I just made some slugs that I would like your opinion on. Not made to be pretty but functional.

The one to the left is a steel cored simple slug housed in a 32mm steel pipe.

The one to the right is a hollow point that I am going to fire at clay.

The question is if you think it will hit with its nose first or if I have to use a longer pipe at the back and/or flange it to make it have more drag.

It will be fired into 20kg of clay at a range of 20-30meters. Probably going to load to 7x since they are 375g each.

What I am looking for is even expansion of the slug at the moment of impact.

Just tell me what you think. I hate putting work into projectiles that are utterly useless.

"Made in France"

- A spud gun insurance.

- A spud gun insurance.

-

iknowmy3tables

- Staff Sergeant

- Posts: 1596

- Joined: Fri Dec 15, 2006 3:57 pm

- Location: maryland

- Has thanked: 3 times

- Been thanked: 9 times

what are the approximate dimensions? how long is the pipe compared to the solid steel slug and how much do they overlap

- SpudFarm

- First Sergeant 3

- Posts: 2571

- Joined: Sat Nov 04, 2006 9:39 am

- Location: Norway Trondheim area

Pipe is 32mm ID and 35mm OD it's 63mm long.iknowmy3tables wrote:what are the approximate dimensions? how long is the pipe compared to the solid steel slug and how much do they overlap

Slug is sticking out in front of the pipe by 2.1cm and there is 4.2cm of space from the back of the slug to the end of the pipe. They overlap by about 2cm.

"Made in France"

- A spud gun insurance.

- A spud gun insurance.

-

iknowmy3tables

- Staff Sergeant

- Posts: 1596

- Joined: Fri Dec 15, 2006 3:57 pm

- Location: maryland

- Has thanked: 3 times

- Been thanked: 9 times

so roughly like the diagram below

my inexperienced judgment says is I think it'll go pretty straight, enough to work if it expands properly, but could really use a ballistics cap of some sort

my inexperienced judgment says is I think it'll go pretty straight, enough to work if it expands properly, but could really use a ballistics cap of some sort

- Attachments

-

- slug.PNG (15.49 KiB) Viewed 3318 times

- SpudFarm

- First Sergeant 3

- Posts: 2571

- Joined: Sat Nov 04, 2006 9:39 am

- Location: Norway Trondheim area

iknowmy3tables wrote:so roughly like the diagram below

my inexperienced judgment says is I think it'll go pretty straight, enough to work if it expands properly, but could really use a ballistics cap of some sort

That was a very precise drawing first of all, I like that people put some time into their work.

Though it makes no difference it might be of interest that where the big and the small hole that makes up the HP itself meet, there is a 45 degree angle to guide material into the lead core.

I have thought about making like ten cuts 1/2" deep along the back of the pipe it is housed in and then bending them into a turbine shape. That should secure me with a perfect hit.

I would like to get this filmed in high speed and perhaps have a "thread pattern" paint job on it to see how the "turbine blades" create spin.

Also, I got my clay today. It was a good deal denser then I expected so it hasn't got any real volume to it. I have two cylinders that is about 5" in diameter and is about 1 foot long.

A .22lr bullet penetrated 4" and made a nice little cavity.

What I am considering is to shoot at something else. Those clay cylinders will just be blown apart completely. Any suggestions on a target? I have shot all my phonebooks

Edit: I think I have found a substitute for the clay. In Norway it is called "kutterspon" and is the kind of chipped wood you put in the spot where cows/horses is sleeping on farms.

It comes compressed in 80cm long and 40x40cm sides. Most of you might know what I am talking about.

Putting this inside a solid container will make it totally reuseable. Won't get any cavity out of it though. The slug should tell the story.

This post is wayyy to long

Last edited by SpudFarm on Mon Apr 26, 2010 4:10 pm, edited 1 time in total.

"Made in France"

- A spud gun insurance.

- A spud gun insurance.