Page 1 of 1

PCP design (start)

Posted: Mon May 18, 2009 9:34 pm

by maverik94

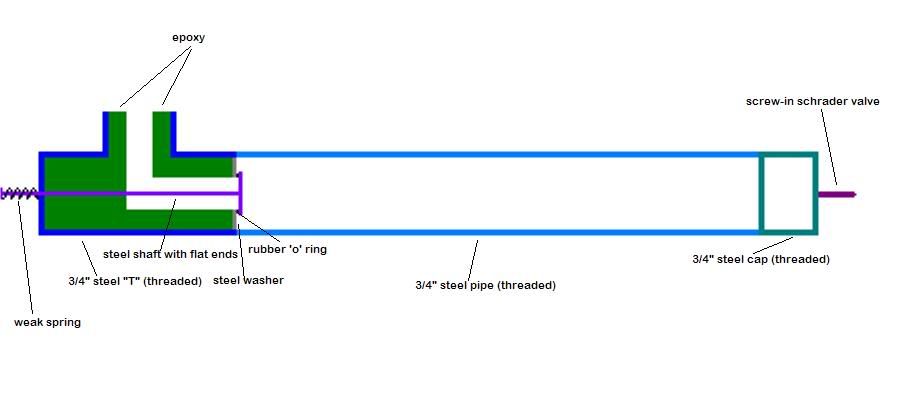

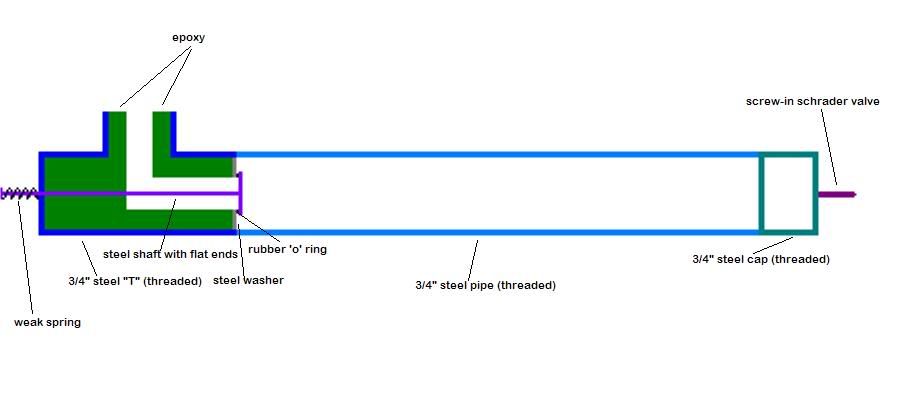

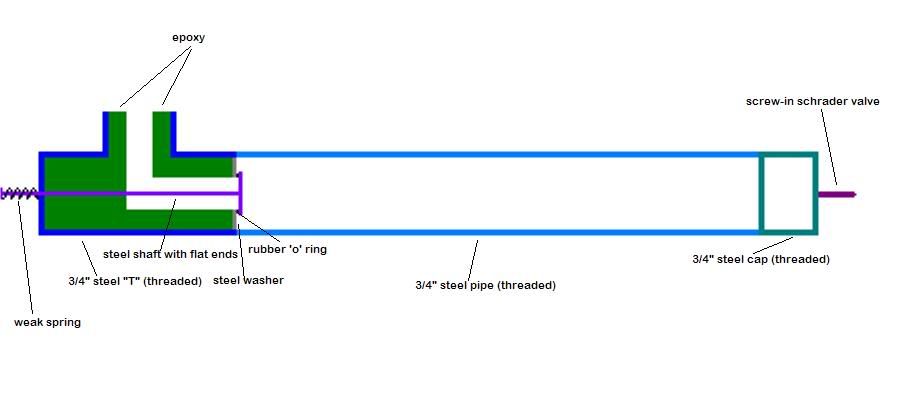

Ok, as I am finishing up my current project, i'm looking to build a pcp pistol next. Here is the design for the chamber and valve setup. Do you think it will work? Any ideas? Also, I will post pictures of the trigger mech and barrel etc later, I already have them drawn on paper, but I still have to draw them on my computer. Thanks!

Posted: Mon May 18, 2009 9:58 pm

by Gippeto

No major problems.

A couple things you might wish to change though;

You will likely realize some benefit by moving the valve face in, closer to the branch of the tee. This will reduce dead space, and improve flow.

The valve stem o-ring WILL depart with the first shot. I promise you. Use a flat washer, and retain it in position.

Or secure the flat washer to the steel washer, and leave the valve stem without a "mounted" seal.

Radius the bend in the tee, this will improve flow and power.

Posted: Tue May 19, 2009 4:20 pm

by maverik94

ok, thanks for the feedback, I will make those changes!

Posted: Tue May 19, 2009 4:39 pm

by jackssmirkingrevenge

What pressure will you be using? Don't forget that commercial PCPs get their power and multi-shot capacity from using either CO<sub>2</sub> at 850 or so psi or HPA at around 3000 psi.

Posted: Tue May 19, 2009 4:54 pm

by POLAND_SPUD

all in all, I think you should buy an airgun... that's gonna be easier and you won't be disappointed with the results...

it's not a big problem to build a homemade high power gun but it's quite difficult to build something really small

Posted: Tue May 19, 2009 5:56 pm

by mark.f

Have you taken a look at a few of the commercial designs for CO<sub>2</sub> or HPA hammer valves? Crosman has been using this basic design for decades...

You could also take a look at the Girandoni air rifles

here, which are PCP by design, and 200 years old to boot. If you'll look towards the bottom of the page, a bicycle shop owner built a version of a PCP air rifle during WWII. Pretty damn neat.

Posted: Tue May 19, 2009 9:31 pm

by maverik94

well, I am planning on using 300-400 psi on this. However, I will be happy if I get 10 somewhat powerfull shots out of it. Do you think that's possible?

@POLAND_SPUD well yeah, I could buy an airgun, but I wouldn't have the feeling of satisfaction I would if I built one myself. I would like to give this a try, and if it ends up sucking, so be it, I'll have learned. Thanks for the feedback yall, anyone else?

Posted: Wed May 20, 2009 1:55 am

by jackssmirkingrevenge

Don't forget that a blowgun is a ready made hammer valve that just needs a hammer, and stuff like a toy cap gun or an

automatic staplercan be adapted as ready made hammers.

Posted: Wed May 20, 2009 3:36 pm

by maverik94

yeah i know, but I would prefer to make something completely homemade. Thanks. Anyone else?

Posted: Wed May 20, 2009 4:22 pm

by CpTn_lAw

Why not invent something new yourself?

Posted: Wed May 20, 2009 4:45 pm

by Brian the brain

Using epoxy will likely give you problems.

You can build a hammer valve like that from small brass fittings without those problems.

Like said before, the oring won;t work.Use a flat rubber washer and superglue it in place.

You will have to go small caliber on this one, just because of the countering force behind the hammer valve at 400 psi.

This means you;ll have to use a small diameter valve, wich limits your barrel size.

I'm very confident it will work based on my previous builds.

You will have to weigh power over number of shots, and you are limited in caliber by using a hammer valve.But a 6 mm 6 shooter is very cool if you do it right!

Homemade all the way baby!!

Posted: Thu May 21, 2009 12:39 am

by jackssmirkingrevenge

maverik94 wrote:I would prefer to make something completely homemade.

Why not cast your own chamber then

I think there's enough effort involved putting pre-existing components not designed for the purpose you're going to use them for together to give enough merit as a homemade project, plus it gives you a much more realistic chance of actually completing your project.

Posted: Thu May 21, 2009 2:32 pm

by maverik94

yeah, I'm thinking 5/16" barrel, ok, would using steel and rubber washers instead of epoxy for the back wall of the valve and epoxy for the size reduction work?

Posted: Thu May 21, 2009 3:00 pm

by jackssmirkingrevenge

Epoxy based construction is only as good as your ability to apply it to the design at hand, that's up to you to figure out

Posted: Thu May 21, 2009 8:37 pm

by maverik94

i have ideas....hehe. I will upload the pics for the rest of the construction soon. As for the construction, I plan to start as soon as the school year is over (next week)