Pimps Piston

Posted: Sat Oct 15, 2005 3:42 pm

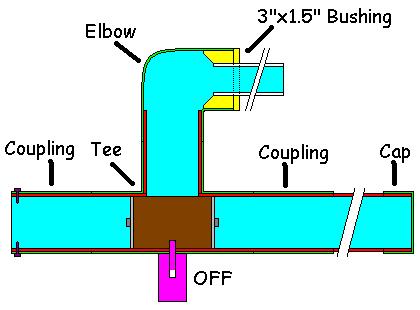

For a couple weeks I have been trying to come up with the most effective piston and this is what I came up with. The only diffrence is that on a normal piston that air is realised behind the piston and since the pressure difference it slides over in attempt to equal the pressure. But the problem I see with that design is that it is still limited to the speed of what ever you have exhausting it (ex: sprikler valve, ball valve). But I think that my design will work better because the air oppisite of the chamber is not ran through a smaller opening. Enough talk know here is a colored key for the components in the pictures.

Color

Green= 3" Fittings (Elbow, Coupling, Cap, and Tee)

Red= 3" Sch 40 Pipe

Pink= Electrical Solenoid

Brown= Piston Body

Gray= Rubber Face fastened to face of Piston body

Yellow= 3"x1.5" Bushing

White= 1.5" Sch 40 Pipe

Purple= Bolts to keep the piston from coming out

Light Blue= Low Pressure

Blue= Higher Pressure

Here is a parts list.

Step One: No pressure in chamber/ Solenoid Off

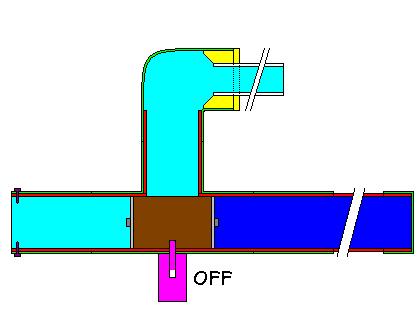

Step Two: Chamber is pressurizing.../ Solenoid Off

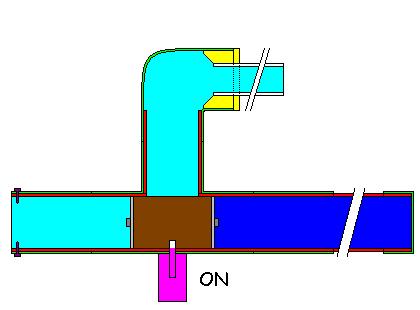

Step Three: Chamber filled to desired pressure/ Soleniod On

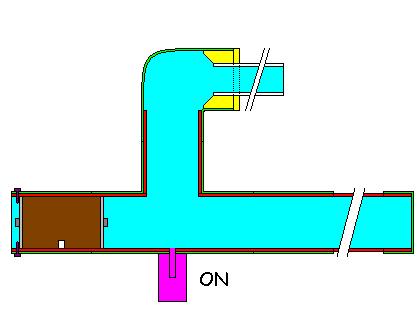

Step Four: Chamber pressure pushing piston back/ Solenoid On

Step Five: Pressure pushes piston over and air realeased into barrel/ Projectile pushed out of barrel/ Solenoid On

Step Six: All air is realeased through barrel/ Solenoid On

Process is repeated by pushing piston back into place then start at Step One.

By posting I want you to tell me if you see any flaws or improvments needed in the design. Please also tell me how you think the overall design will work. If there is anything else you would like to say feel free to say it.

Color

Green= 3" Fittings (Elbow, Coupling, Cap, and Tee)

Red= 3" Sch 40 Pipe

Pink= Electrical Solenoid

Brown= Piston Body

Gray= Rubber Face fastened to face of Piston body

Yellow= 3"x1.5" Bushing

White= 1.5" Sch 40 Pipe

Purple= Bolts to keep the piston from coming out

Light Blue= Low Pressure

Blue= Higher Pressure

Here is a parts list.

Step One: No pressure in chamber/ Solenoid Off

Step Two: Chamber is pressurizing.../ Solenoid Off

Step Three: Chamber filled to desired pressure/ Soleniod On

Step Four: Chamber pressure pushing piston back/ Solenoid On

Step Five: Pressure pushes piston over and air realeased into barrel/ Projectile pushed out of barrel/ Solenoid On

Step Six: All air is realeased through barrel/ Solenoid On

Process is repeated by pushing piston back into place then start at Step One.

By posting I want you to tell me if you see any flaws or improvments needed in the design. Please also tell me how you think the overall design will work. If there is anything else you would like to say feel free to say it.