I have a quickly made spud cannon and I'm trying to get it to have similar performance every shot. It boils down to 2 mayor issues:

-getting the fuel/air mixture to combust not burn,

-measuring the amount of propellant injected.

I also have the problem with propellant escaping before I manage to close the chamber which is something I can solve but there's probably a better solution then what I had in mind.

Did anybody experience these issues and managed to solve them?

Just in case anybody asks there's no igniter there's just a small hole drilled in the back. I just put a propane torch near it and there's a 30/10/60 split of it either burning, not doing anything or firing.

How do you get consistent performance out of a "cheap" cannon?

- jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

The solution is to meter your fuel, there are several ways you can go about this.

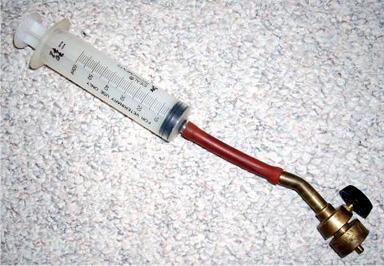

I personally prefer syringe injection but it depends on the size of the cannon, above a certain chamber volume you won't find a syringe big enough.

I personally prefer syringe injection but it depends on the size of the cannon, above a certain chamber volume you won't find a syringe big enough.

hectmarr wrote:You have to make many weapons, because this field is long and short life

-

Bazooka

- Private

- Posts: 11

- Joined: Mon Jul 25, 2022 8:44 pm

- Has thanked: 1 time

- Been thanked: 9 times

It's simple. You use a propane Torch to ignite ? Use it for fueling !

Propane torches make the perfect mix by using the Venturi effect.

The Problem is: A Venturi mix has to flow without resistance, so it can't be used with a loaded barrel....normally.

But if I use a "over pressure" valve (we use cheap ones on our garden hoses) between chamber and barrel, it will make the mix flow and in the moment of ignition the valve closes and leads all pressure to barrel. I use this system in all of my launchers.

The trick is, to make the chamber a little bit bigger as needed to fire the projectile, because you need energy (little) to close the valve AND shot.

Look for my Bottle Bazooka and Valve Gun. Both use this system and Torches for the perfect mix without issues. You only have to meter by time. But full is full, and everything to much will go through the valve. I can't "overload"...

Everytime a perfect shot.

Propane torches make the perfect mix by using the Venturi effect.

The Problem is: A Venturi mix has to flow without resistance, so it can't be used with a loaded barrel....normally.

But if I use a "over pressure" valve (we use cheap ones on our garden hoses) between chamber and barrel, it will make the mix flow and in the moment of ignition the valve closes and leads all pressure to barrel. I use this system in all of my launchers.

The trick is, to make the chamber a little bit bigger as needed to fire the projectile, because you need energy (little) to close the valve AND shot.

Look for my Bottle Bazooka and Valve Gun. Both use this system and Torches for the perfect mix without issues. You only have to meter by time. But full is full, and everything to much will go through the valve. I can't "overload"...

Everytime a perfect shot.

- jimmy101

- Sergeant Major 2

- Posts: 3210

- Joined: Wed Mar 28, 2007 9:48 am

- Location: Greenwood, Indiana

- Has thanked: 6 times

- Been thanked: 18 times

- Contact:

Pretty slow and wasteful of fuel. You need to completely replace the air in the chamber so you probably need to use at least several times the volume of the chamber from your torch.Bazooka wrote: ↑Wed Jul 27, 2022 3:56 pmIt's simple. You use a propane Torch to ignite ? Use it for fueling !

Propane torches make the perfect mix by using the Venturi effect.

The Problem is: A Venturi mix has to flow without resistance, so it can't be used with a loaded barrel....normally.

But if I use a "over pressure" valve (we use cheap ones on our garden hoses) between chamber and barrel, it will make the mix flow and in the moment of ignition the valve closes and leads all pressure to barrel. I use this system in all of my launchers.

The trick is, to make the chamber a little bit bigger as needed to fire the projectile, because you need energy (little) to close the valve AND shot.

Look for my Bottle Bazooka and Valve Gun. Both use this system and Torches for the perfect mix without issues. You only have to meter by time. But full is full, and everything to much will go through the valve. I can't "overload"...

Everytime a perfect shot.

Much simpler to just use a hunk of rubber hose to connect your torch (with out the air mixer) to a syringe and then inject the EXACT amount of pure fuel into your chamber without having to waste so much fuel.

spud_wiki/index.php?title=Fuel_meter

-

Bazooka

- Private

- Posts: 11

- Joined: Mon Jul 25, 2022 8:44 pm

- Has thanked: 1 time

- Been thanked: 9 times

What waste ? I need 3 seconds to fully load. Without any metering. Who cares for a minimum amount of gas going out ? It depends on the type of Lighter or propanetorch how long it takes.

And I don't have to fill the whole system with mix and get all the air out. It's enough to fill the chamber, because it's bigger as needed.

My intention is to simply press a button to shot.

Maybe i make some closeups today.

Look for the Gardena Valve in the pictures. It sits on a t-piece and is normally open. In the moment of ignition, it closes with little pressure and leads Al gases to the projectile.

Another valve shuts the chamber from the Lighter (Because the nozzle gets dirty, if it is open).

Try it with some old tubes.

To handle a syringe to fuel for a little bangbang....costs to much time. Load, press button, fun

But, next will be with Arduino and electronic load and fire.

And I don't have to fill the whole system with mix and get all the air out. It's enough to fill the chamber, because it's bigger as needed.

My intention is to simply press a button to shot.

Maybe i make some closeups today.

Look for the Gardena Valve in the pictures. It sits on a t-piece and is normally open. In the moment of ignition, it closes with little pressure and leads Al gases to the projectile.

Another valve shuts the chamber from the Lighter (Because the nozzle gets dirty, if it is open).

Try it with some old tubes.

To handle a syringe to fuel for a little bangbang....costs to much time. Load, press button, fun

But, next will be with Arduino and electronic load and fire.

-

Bazooka

- Private

- Posts: 11

- Joined: Mon Jul 25, 2022 8:44 pm

- Has thanked: 1 time

- Been thanked: 9 times

Now. It actually works. So I don't really care, if it is not the old school way.

And WHY is it a "terrible way" ? I fuel it with a half-pressed button. If I press full after a few seconds: baaang. Without any issues. What is wrong with that ? Because I use a new way, that works ? It is a "self-sealing" system, like a one stroke engine or one of this butane-nailguns. Or a crowcanon in Wineyards...

Maybe it's not the "greenest", extinction rebellion and Fridays for future way...

It's dirty, fast and WORKS

-

Bazooka

- Private

- Posts: 11

- Joined: Mon Jul 25, 2022 8:44 pm

- Has thanked: 1 time

- Been thanked: 9 times

Easyest Nerf Cannon with direct fueling and firing I ever made.

It was a 30min Project. This morning.

The chamber is waaayyy tooo big. So U see what happens with normal Nerf Darts...

But this is only to show the direct fueling by a Torch WITH use of a bigger Lighter or Torch. 4 seconds load and booom.

It consists of Parts laying around. The. Chamber is a aluminium bottle.

For the valve you have to cut the male part and use a very weak spring to hold it normally open and close it when firing. It's a little tricky to find the right distance between fueling without resistance and closing without loosing to much energy. This depends all on this little bastard spring. And I tried a lot !

It was a 30min Project. This morning.

The chamber is waaayyy tooo big. So U see what happens with normal Nerf Darts...

But this is only to show the direct fueling by a Torch WITH use of a bigger Lighter or Torch. 4 seconds load and booom.

It consists of Parts laying around. The. Chamber is a aluminium bottle.

For the valve you have to cut the male part and use a very weak spring to hold it normally open and close it when firing. It's a little tricky to find the right distance between fueling without resistance and closing without loosing to much energy. This depends all on this little bastard spring. And I tried a lot !

-

hectmarr

- Sergeant

- Posts: 1064

- Joined: Sat May 07, 2016 3:49 pm

- Location: Argentina

- Has thanked: 274 times

- Been thanked: 276 times

- Contact:

The "lost gas" method is what I use for my air pump guns and it works perfectly fine. Yes, it is true that it wastes a little gas but it makes everything more practical and faster to refuel. The trade-in is a practical thing for a little more butane in the process. Without hesitation, I accept the "cost" and those of us who manufacture weapons and who we show here know this well.

It would be interesting to measure the time that is used to refuel using both methods, without a doubt it is MUCH faster and equally accurate using Bazoka. You don't have to unplug anything!

This is the simple system. You only press the valve of the commercial aerosol for one second, which is enough for the butane that enters to sweep all the air and the syringe that fills only with butane, (red line) and then you only use the pump to introduce the mixture into the weapon. The suction of the pump when it draws air introduces the gas inside the pump cylinder and then sends it mixed with the air inside the combustion chamber, it is infallible. The internal volume of the syringe is the dose, in this case 5.5 ml of butane. When the air is sucked in by the piston of the pump, it drags all the butane that was already in the syringe. Very practical. If you use a piece of hose used in pneumatics, for example with an internal diameter of 2.5 mm, you have 21 cm to be a cm3. You can calibrate with much more precision the volume of butane, increasing or decreasing the length, with infinite more precision than with a syringe. For someone to try to measure 0.01 cm3 less with a common syringe, it is impossible! With the hose I describe, you only cut 2.1mm and you're good to go. In addition, the air in the hose is displaced by the butane with much less butane waste, and you eliminate some randomness caused by turbulence in a dispenser with a syringe geometry.

It is clear that the procedure that I expose here is to pressurize hybrid weapons but the point is that wasting a little gas and / or air, in any case, is a cheap price to achieve something practical, that can be fired without having to carry out a paraphernalia of connections and disconnections and measurements etc...that's my point.

It would be interesting to measure the time that is used to refuel using both methods, without a doubt it is MUCH faster and equally accurate using Bazoka. You don't have to unplug anything!

This is the simple system. You only press the valve of the commercial aerosol for one second, which is enough for the butane that enters to sweep all the air and the syringe that fills only with butane, (red line) and then you only use the pump to introduce the mixture into the weapon. The suction of the pump when it draws air introduces the gas inside the pump cylinder and then sends it mixed with the air inside the combustion chamber, it is infallible. The internal volume of the syringe is the dose, in this case 5.5 ml of butane. When the air is sucked in by the piston of the pump, it drags all the butane that was already in the syringe. Very practical. If you use a piece of hose used in pneumatics, for example with an internal diameter of 2.5 mm, you have 21 cm to be a cm3. You can calibrate with much more precision the volume of butane, increasing or decreasing the length, with infinite more precision than with a syringe. For someone to try to measure 0.01 cm3 less with a common syringe, it is impossible! With the hose I describe, you only cut 2.1mm and you're good to go. In addition, the air in the hose is displaced by the butane with much less butane waste, and you eliminate some randomness caused by turbulence in a dispenser with a syringe geometry.

It is clear that the procedure that I expose here is to pressurize hybrid weapons but the point is that wasting a little gas and / or air, in any case, is a cheap price to achieve something practical, that can be fired without having to carry out a paraphernalia of connections and disconnections and measurements etc...that's my point.

- jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

- jackssmirkingrevenge

- Five Star General

- Posts: 26216

- Joined: Thu Mar 15, 2007 11:28 pm

- Has thanked: 576 times

- Been thanked: 347 times

There is a caveat in that "pretty is as pretty does", so when something is functional, there is a certain beauty in it regardless of its aesthetic attributes.

hectmarr wrote:You have to make many weapons, because this field is long and short life

-

hectmarr

- Sergeant

- Posts: 1064

- Joined: Sat May 07, 2016 3:49 pm

- Location: Argentina

- Has thanked: 274 times

- Been thanked: 276 times

- Contact:

If you're right. There is an aesthetic of the function, which is independent of the aesthetic itself, (easier to achieve, I think). I was referring to that aesthetic "in itself" when I say Ugly. For the rest, everything that makes holes made at home is basically beautiful!jackssmirkingrevenge wrote: ↑Wed Aug 10, 2022 9:55 amThere is a caveat in that "pretty is as pretty does", so when something is functional, there is a certain beauty in it regardless of its aesthetic attributes.