Show us your pneumatic spud gun! Discuss pneumatic (compressed gas) powered potato guns and related accessories. Valve types, actuation, pipe, materials, fittings, compressors, safety, gas choices, and more.

-

experament-u2

- Specialist 4

- Posts: 469

- Joined: Tue Dec 26, 2006 11:18 pm

Sat Apr 07, 2007 7:10 am

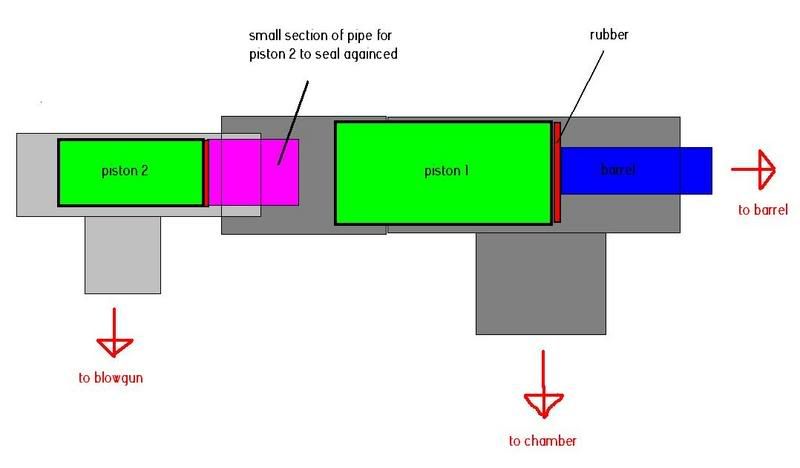

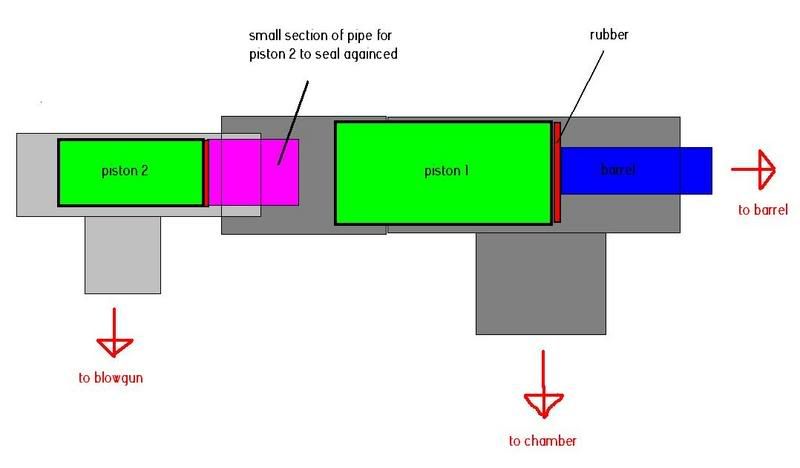

ok so heres my piston gun so far

it is my first and i know its not very good

anyway the blowgun is to small to vent it so i was thinking since i need the blowgun for my overall desgin could i vent my larger piston with a smaller one and use the blow gun to vent the small one?

heres a diagram of the set up plz if it can be refined to work better plz help

plz can anybody help me

-U2

-

Hotwired

- First Sergeant 3

- Posts: 2599

- Joined: Fri Oct 13, 2006 5:51 am

- Location: UK

Sat Apr 07, 2007 7:45 am

You can use a piston valve to trigger another. I've drawn up designs which use smaller qev's to dump the pilot of a larger qev.

I think you have the ports the wrong way round there.

The branch of the small tee should be connected to the pilot port of the first.

-

Hawkeye

- Specialist 4

- Posts: 462

- Joined: Sun Jan 21, 2007 7:12 pm

Sat Apr 07, 2007 7:56 am

How is the blowgun too small to vent? You can use a schrader to vent the pilot of a gun that size.

You should just attach it directly rather than adding a huge pilot volume with the hose.

-

jrrdw

- Moderator

- Posts: 6572

- Joined: Wed Nov 16, 2005 5:11 pm

- Location: Maryland

- Has thanked: 39 times

- Been thanked: 22 times

-

Contact:

Sat Apr 07, 2007 8:30 am

I have to kinda agree with Hawkeye, you can shorten the hose a little at a time untill it fires your cannon. If you get to no hose and it still don't fire, the pilot volume is to big to be vented with a blow gun by its self. Then i sagest a modded sprinkler valve, but i dought if you will need that on this cannon. By the way, you don't give yourself enough credit, it's a good looking cannon to me!

-

Matheusilla

- Specialist

- Posts: 140

- Joined: Tue Feb 13, 2007 7:43 pm

Sat Apr 07, 2007 8:46 am

yeah, it looks good dude, give yourself a break. But ya, you might want to reduce the volume of air that needs to exhausted from the pilot side. The blowgun should be able to actuate the large piston but a piston actuating another piston would be real neat.

-

Solo

- Private 2

- Posts: 33

- Joined: Fri Jan 05, 2007 10:45 am

Sat Apr 07, 2007 9:25 am

What size is that tee? I made a 1" piston valve triggered by a 1/2" piston valve triggered by a blowgun. It really sucked b/c of the complexity and b/c I had some leaky joints, so I just cut it up. But my current gun has a 1.25" tee piston vented by a blowgun and it works admirably. I'd suggest taking the piston out and trying to make it a little more of an airtight fit with the cylinder it slides in. What's your piston made out of?

BTW, very nice looking gun for a first try. You'll have fun with that when you get it working.

-

experament-u2

- Specialist 4

- Posts: 469

- Joined: Tue Dec 26, 2006 11:18 pm

Sat Apr 07, 2007 9:32 am

thax solo im trying to add a oring to my piston now witch is made out of 3/4 poly pipe with neoprine glued on one side

-

Velocity

- Sergeant

- Posts: 1039

- Joined: Tue Feb 07, 2006 5:42 pm

Sat Apr 07, 2007 9:45 am

Honestly, blowguns do exactly that: they blow. They are really only good for actuating QEV's, for they have a tiny amount of pilot volume. If you put on an o-ring or two, it probably would work, but if I were you, I would just add a 1/4" QEV to the back of the piston valve and attach the blowgun to that; would work a lot better. Or you could just attach a 1/4" ball valve.

Also: in your diagram, I would make the secondary piston valve much smaller than the primary. If it is just a tiny bit smaller, then I doubt the blowgun would be able to exhaust it anyways.

And yeah, this is a very nice looking cannon. Very clean. I am sure it will be fun to use once you get all the bugs worked out.

-

Hawkeye

- Specialist 4

- Posts: 462

- Joined: Sun Jan 21, 2007 7:12 pm

Sat Apr 07, 2007 11:52 am

You might want to question your piston workmanship if you can't get a blowgun to work the piston. I don't even mod them and they work great.

-

Velocity

- Sergeant

- Posts: 1039

- Joined: Tue Feb 07, 2006 5:42 pm

Sat Apr 07, 2007 11:55 am

Hawkeye wrote:You might want to question your piston workmanship if you can't get a blowgun to work the piston. I don't even mod them and they work great.

What size piston valve do you build that allows a blowgun to work properly as a pilot valve? And what type of blowgun do you use?

and experament u2, is that a slipxslip elbow?!

-

Hawkeye

- Specialist 4

- Posts: 462

- Joined: Sun Jan 21, 2007 7:12 pm

Sat Apr 07, 2007 12:33 pm

I use copper pipe of 3/4-1 inch to house the piston.

I realize you need more flow when you are building large diameter pistons but most of the complaints seem to come from guys trying to build smaller guns.

I just use a regular blowgun that comes with a compressor.

-

experament-u2

- Specialist 4

- Posts: 469

- Joined: Tue Dec 26, 2006 11:18 pm

Sat Apr 07, 2007 8:31 pm

i added a oring last night and cut down the pistons size to about 200mm now it works perfectly thank you for all your help and special thanks to killa and chaos