Every last Sprinkler valve I buy leaks, and I can’t even get a piston valve to work right!

But that’s not the reason I started this thread, this is:

I’m currently working on a Toolies style piston valve, and I have been for weeks… make that months, over three prototypes I’ve encountered the following problems:

Before I list the problems some general specifications:

All the valve prototypes have been built inside a piece of 1.5 inch SCH40 PVC pipe about a foot long, they have all been 1inch porters, and they have all been made to pilot by simply unhooking it from the gas supply (1/4 inch quick disconnect).

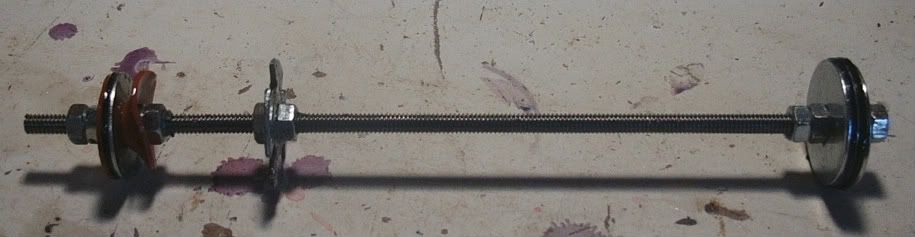

The pistons were made from a piece of all-thread with fender washers and rubber disks for seals.

X1:

Never fully sealed

Open incredibly slow (there was a good delay between pilot opening and main valve opening)

Seal face gets sucked into the barrel port

Seal face ripped

X2: *changes: piston rod .5 inch longer*

Never fully sealed

Seal face gets sucked into the barrel port

X3: *changes: piston rod is a full 2 inches longer then the X1’s in hopes of achieving usable performance and back of valve has a threaded adapter to permit access to piston*

Doesn’t open

When it does it has very little power.

I’ve experimented with everything from neoprene washers to gasket material to leather washers for seal faces, nothing works.

On average pilot volume is about 2in^2.

Here are pictures of the X2:

Parts layout:

Piston:

Completed and glued:

I’ll get pictures of the X3 later.

Any help or advice would be very much appreciated.

Thanks All!