Now i have my barrel and chamber and have put together my cannon! Which is currently the largest one i've ever built, it has a 2 meter long 6/4 (48mm) barrel and a 24l overkill compressor tank.

Right now it's in it's "crude but functional" form.

Things that still need to happen:

Paint job (Maybe)

Carriage (Most likely)

More elegant triggering system (Definitely)

One 3/8 to 1/4 adapter for the pressure gauge instead of the current ghetto rigged setup (Definitely)

Leak proofing (Definitely)

Took several test shots, a few with just air from 3 to 5 bar and even then the cannon rolled back on its wheels!

And two shots with ammo, one potato and one solid wax candle which fitted inside the barrel nicely. Both shots were at about 8 bar

The potato exploded as soon as it left the barrel and the candle disappeared into the sky... I'm going to build some tracer rounds for it to see how far she goes

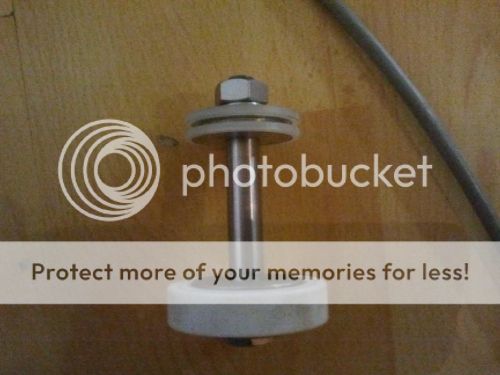

Funny thing i noticed though; When the pressure in the main chamber is at about 8 bars i need to put around 12 bar or more on the pilot in order to prevent it from leaking air from the barrel, so connecting the chamber to the pilot was not an option. Luckily i do have an an HPA rig for this.