My project - HPA powered SMG for .50 lead balls

Posted: Fri Oct 12, 2012 5:42 am

Hello. First post here, so let me give a brief background. I am into guns, and having shot various machine guns in the Army, I sure would enjoy being able to shoot one for fun. I live in a state which doesn't have any way to get a license for Class 3 machine guns, so the only legal option is to go with an air powered non-firearm. I've had several paintball markers, worked with CO2 regulators and lawn sprinkler valves in a few simple air cannons, and have some understanding of how all the valves involved work. By day, I am an engineer and my talents center on being able to design 3D models of precise mechanical components.

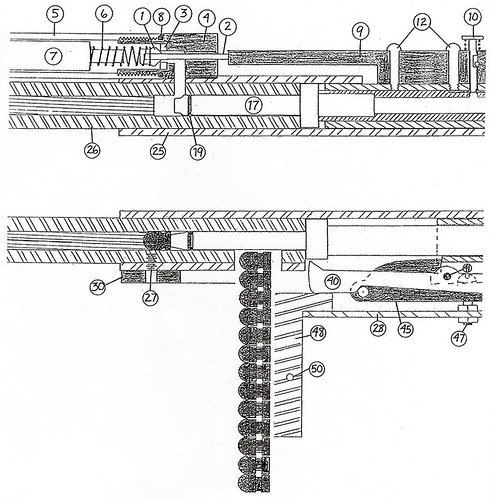

I had been looking at the Caselman air powered SMG blueprints for a while, and in the last few weeks have modeled it all into 3D. I have many disagreements with the way that gun works, and finally have decided I would rather spend my time designing one from the ground up, than to spend hundreds for our machine shop to make parts for the Caselman design, and end up with mediocre performance at best.

To this end, my plan is to build a full automatic air rifle utilizing a rifled .50 caliber barrel from a muzzle loader, and to run HPA through the internals, not regulated down to 800 PSI or less like most paintball markers, but to actually be using full bottle pressure inside to give the rounds as much power as possible. Using various attempts at calculating it, I believe if I were to use the 290 grain PowerBelt rounds and an internal pressure of 3000 PSI, then with a 24 inch barrel I should be able to achieve round performance similar to that of a .45ACP pistol round.

My use of Google has been bringing me to this forum frequently enough, I figured I'd just register and might as well start talking with you guys here about my project. Most of my concerns will be how I can put valves together that will seal, hold, and survive the wear of usage. I don't know how much an O-ring can be trusted to seal at 3000 PSI, for example, or whether that's laughably impossible and any seals must be press-fit, and any valves must be poppet-style (not spool). I have been trying to focus the design on what I would consider to fire from a "locked" breech - that is, rather than like a paintball marker where barrel pressure drives the round forward, and drives the bolt back to recock, instead I would want to barrel pressure to only drive the round forward, and for the bolt to actually be held in a sealed position by the barrel pressure, only releasing to recock after pressure has dropped (and spring force takes over). I will try to get some pictures put together of the CAD models I've been working with on this, to better illustrate my concepts for how the action would work.

Anyways, gotta run for now, but I hope to return and provide more details, pictures, and so forth. If anyone is looking seriously at the Caselman air powered SMG, I would be more than happy to share my CAD model of it with you (I can export it as STP files).

I had been looking at the Caselman air powered SMG blueprints for a while, and in the last few weeks have modeled it all into 3D. I have many disagreements with the way that gun works, and finally have decided I would rather spend my time designing one from the ground up, than to spend hundreds for our machine shop to make parts for the Caselman design, and end up with mediocre performance at best.

To this end, my plan is to build a full automatic air rifle utilizing a rifled .50 caliber barrel from a muzzle loader, and to run HPA through the internals, not regulated down to 800 PSI or less like most paintball markers, but to actually be using full bottle pressure inside to give the rounds as much power as possible. Using various attempts at calculating it, I believe if I were to use the 290 grain PowerBelt rounds and an internal pressure of 3000 PSI, then with a 24 inch barrel I should be able to achieve round performance similar to that of a .45ACP pistol round.

My use of Google has been bringing me to this forum frequently enough, I figured I'd just register and might as well start talking with you guys here about my project. Most of my concerns will be how I can put valves together that will seal, hold, and survive the wear of usage. I don't know how much an O-ring can be trusted to seal at 3000 PSI, for example, or whether that's laughably impossible and any seals must be press-fit, and any valves must be poppet-style (not spool). I have been trying to focus the design on what I would consider to fire from a "locked" breech - that is, rather than like a paintball marker where barrel pressure drives the round forward, and drives the bolt back to recock, instead I would want to barrel pressure to only drive the round forward, and for the bolt to actually be held in a sealed position by the barrel pressure, only releasing to recock after pressure has dropped (and spring force takes over). I will try to get some pictures put together of the CAD models I've been working with on this, to better illustrate my concepts for how the action would work.

Anyways, gotta run for now, but I hope to return and provide more details, pictures, and so forth. If anyone is looking seriously at the Caselman air powered SMG, I would be more than happy to share my CAD model of it with you (I can export it as STP files).