Wow... it's been a while since I've checked in...

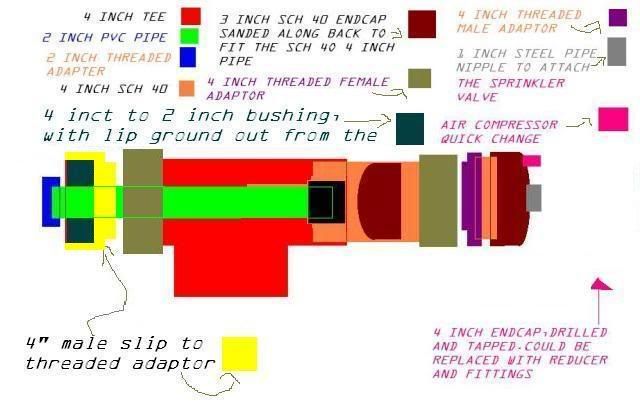

Anyway, I finally got enough extra cash to pick up some parts to build this valve, but while looking I change everything up to make it a hell of a lot more efficient lol.

First of all, I fit the whole thing in a 3x3x2 inch tee. I had to use a 2 inch top because with a 3 inch, whenever the end cap hits the rubber donut, theres a huge hole behind it caused by the curve of the pipe. a 2inch however fits perfect.

secondly, i made the valve a full 4 inch valve by allow the air to never narrow more than the inside of the donut. if you notice, i have a 4x3 inch flush reducer, but thats b/c i was a bit indescisive. instead, im going to use another threaded adapter so that i can use interchangeable barrelss, and a total 4 inch barrel without the air ever narrowing down to 3 inches, as it is now.

in the rear, i still havent decide quite how to trigger it, but im using an endcap so that if i ever need to replace the endcap/piston, it'll be easy. what im thinking about doing is just tapping a quick connect towards the side of the endcap, and then porting a 1 inch hole right on the square nob and attaching a modified sprinkler valve.

all the pieces

the rubber donut inside the tee

shot from the top so you can see how far it goes

the 4x3 flush reducer. not gonna get glued in though... im gonna just put a threaded adapter so that i can put interchangeable barrels, including a complete 4 inch barrel, on without the air ever narrowing more than the inside of the donut.

shot from the end.

theres the piston on the inside, butted against the donut.

and theres the gap.

from the back

with the adapter on.

and finally the endcap.

ya'll let me know what you think, im still a newb, so im willing to take all comments, tips, insights, ideas, criticisms, whatever you got.