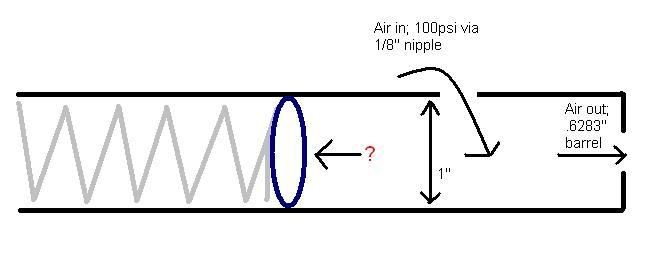

boilingleadbath wrote:1) Technically, the direction of flow in the chamber does matter; if it changes, you get a localized high-pressure region.

I don't expect this to be significant in this situation.

2) Air leaves through holes for a reason: pressure. And the higher the pressure, the faster it leaves.

Thus, one finds that the pressure in the chamber you've drawn a picture of will not be either zero nor equal to the inlet pressure.

You are correct, the "1/8 inch nipple" inlet is going to introduce a pretty big pressure drop at that point.

Yes, the air flows because of a pressure gradient, no gradient then no flow. But, air flows at nearly the speed of sound, so the actual pressure gradient in the system, beyond the inlet restriction, is extremely small. The pressure gradient from the piston top to the butt of the ammo is going to be miniscule. Indeed, the gradient may be backwards, that is, the pressure on the piston will be greater than the pressure on the ammo if the ammo is moving faster than the piston.

The air also has momentum, but since the density of dry air at 120 PSIG is only about 10g/liter it's momentum is pretty small.

The peak pressure in the chamber may or may not reach the inlet pressure, it all depends on the characteristics of the system. How massive is the projectile? How much friction is there? What are the air flow characteristics through the fairly small inlet port?

From a design standpoint, the gun / piston / return spring etc. should be designed assuming the worse case scenario, the chamber reaches the inlet pressure at some point in the firing cycle.