Show us your pneumatic spud gun! Discuss pneumatic (compressed gas) powered potato guns and related accessories. Valve types, actuation, pipe, materials, fittings, compressors, safety, gas choices, and more.

-

jrrdw

- Moderator

- Posts: 6572

- Joined: Wed Nov 16, 2005 5:11 pm

- Location: Maryland

- Has thanked: 39 times

- Been thanked: 22 times

-

Contact:

Wed Jan 02, 2008 4:40 pm

Wont that union hold the diaphram in one place? Thus not allowing it to move, keeping it from working?

-

jrrdw

- Moderator

- Posts: 6572

- Joined: Wed Nov 16, 2005 5:11 pm

- Location: Maryland

- Has thanked: 39 times

- Been thanked: 22 times

-

Contact:

Wed Jan 02, 2008 4:50 pm

sandman wrote:the diaphragm is flexible so it can stretch, hence why sprinkler valves work

Wont it be clamped all the way around? It has to let the pilot chamber vent.

-

sandman

- Corporal 2

- Posts: 672

- Joined: Thu Mar 15, 2007 6:59 pm

Wed Jan 02, 2008 4:57 pm

jrrdw wrote:

Wont it be clamped all the way around? It has to let the pilot chamber vent.

a sprinkler valve is clamped all the way around

and when it vents the force stretches it back and allows the air into the barrel

-

BigJon

- Specialist

- Posts: 120

- Joined: Wed May 30, 2007 12:21 pm

Wed Jan 02, 2008 5:01 pm

The diaphragm is accually a little bigger than the diameter of the union so it can move back and forth a little bit i think. Kinda hard to explain so sorry if you don't understand.

-

Easterbunny

- Private

- Posts: 19

- Joined: Wed Jan 02, 2008 1:24 pm

Wed Jan 02, 2008 6:30 pm

would it be easier and peform better to make it a piston insted? somthing like an end cap with a rubber disk , bolt washer and a nut. put a couple of holes in the endcap for airflow. here

-

Attachments

-

-

BigJon

- Specialist

- Posts: 120

- Joined: Wed May 30, 2007 12:21 pm

Wed Jan 02, 2008 6:34 pm

If you use the piston method you won't need to drill holes in the endcap (piston) unless it is absolutely air tight. I also think a piston would be easier to make but thats just me.

-

BigJon

- Specialist

- Posts: 120

- Joined: Wed May 30, 2007 12:21 pm

-

Easterbunny

- Private

- Posts: 19

- Joined: Wed Jan 02, 2008 1:24 pm

Wed Jan 02, 2008 7:14 pm

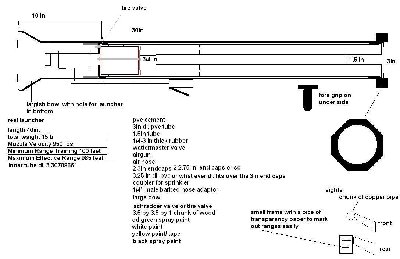

ok here is the updated plans, i hope to make the body tube removeable to service the launcher if it is nesscary with a pistion

-

Attachments

-

-

MrCrowley

- Moderator

- Posts: 10078

- Joined: Fri Jun 23, 2006 10:42 pm

- Location: Auckland, New Zealand

- Been thanked: 3 times

Wed Jan 02, 2008 7:16 pm

sandman wrote:wouldn't the Piston OD and the Barrel ID be the same thing?

No otherwise the piston wouldn't work

And if the piston O.D = Barrel I.D wouldn't the piston go inside the barrel

The piston needs an exposed area that has pressure forcing it back, that's why pistons work so well.

So the O.D of the piston could be say 8cm and the I.D of the seat(barrel) could be 7cm.