Potatoes last one shot, so build reusable! Discuss ammo designs and ideas. Tough to find cannon part or questions? Ask here!

-

Counterstriker

- Specialist 4

- Posts: 426

- Joined: Tue May 29, 2007 2:06 pm

Wed Mar 12, 2008 7:36 pm

hubb017 wrote:Sorry for not clarifying (and, yes, I simply edited the original pic).

First, the piece around the piston is something I did not erase from the original pic. It is whatever you intended it to be.

As far as connecting it together, tap a 1/8" npt hole in the end of the cap and put a pipe nipple (short piece of pipe threaded on both ends) through the hole. Secure the tee to that, then the schrader and blowgun.

Do I really have to drill a hole through it?

Click me!

I don't think he drilled any holes. I know that it is only 1/2", but I would guess they have reducers for a 3/4" or 1". Thanks for you patience

Last edited by

Counterstriker on Wed Mar 12, 2008 7:45 pm, edited 2 times in total.

-

Counterstriker

- Specialist 4

- Posts: 426

- Joined: Tue May 29, 2007 2:06 pm

Wed Mar 12, 2008 7:38 pm

Counterstriker wrote:hubb017 wrote:Sorry for not clarifying (and, yes, I simply edited the original pic).

First, the piece around the piston is something I did not erase from the original pic. It is whatever you intended it to be.

As far as connecting it together, tap a 1/8" npt hole in the end of the cap and put a pipe nipple (short piece of pipe threaded on both ends) through the hole. Secure the tee to that, then the schrader and blowgun.

Do I really have to drill a hole through it?

Click me!

I don't think he drilled anyholes. I know that it is only 1/2", but I would guess they have reducers for a 3/4" or 1". Thanks for you patience

-

Hubb

- First Sergeant 2

- Posts: 2390

- Joined: Mon May 28, 2007 8:39 am

- Location: South Georgia

-

Contact:

Wed Mar 12, 2008 8:07 pm

I'm sorry. I was thinking of a larger PVC launcher. I guess that came from the diagram. With a smaller one, you could get a bushing (if necessary) to do the same.

-

Counterstriker

- Specialist 4

- Posts: 426

- Joined: Tue May 29, 2007 2:06 pm

Wed Mar 12, 2008 8:56 pm

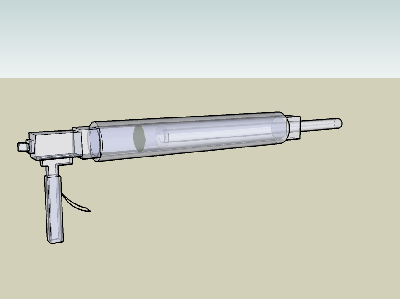

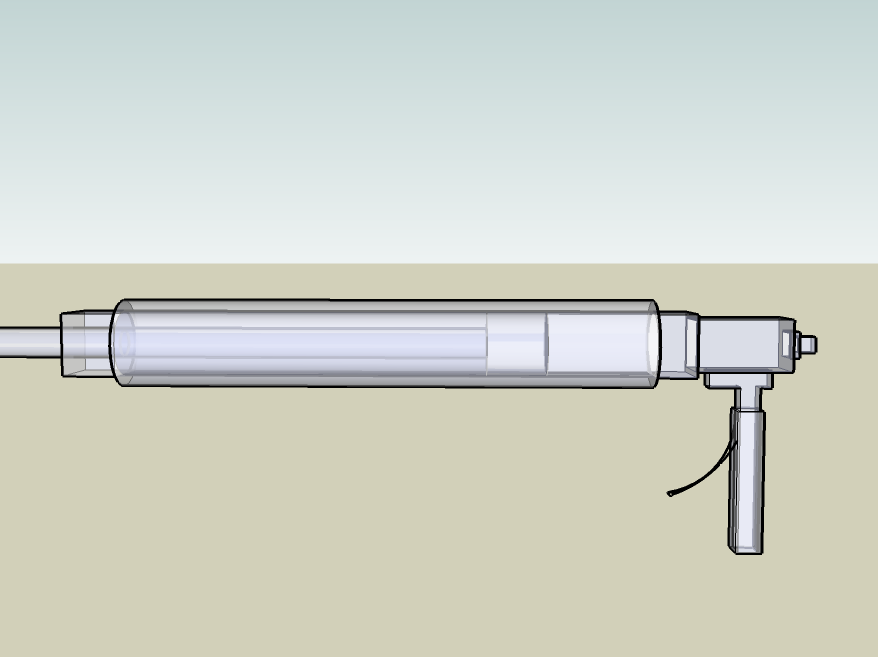

Ok I made a drawing on google sketchup.. it sucks because its the second thing I ever made..but I don't know how to convert SKBs..

-

Counterstriker

- Specialist 4

- Posts: 426

- Joined: Tue May 29, 2007 2:06 pm

Thu Mar 13, 2008 8:00 pm

Hey! Sorry for the triple post

. It won't let me delete.. (can a mod help me out

) But this is my basic design. I am hoping to order the epoxy this weekend, I will see if home depot has it but last time I was there it was all thick junk..

-

Attachments

-

- Airgun

-

- New view

- Untitled.png (20.55 KiB) Viewed 1934 times

-

Counterstriker

- Specialist 4

- Posts: 426

- Joined: Tue May 29, 2007 2:06 pm

Thu Mar 13, 2008 9:16 pm

elitesniper wrote:looks good, but is that square in the fount going to be a clean out or something?

I just put it there to show that there will be some reducers : ) Will they have reducers to.. 8mm or.. 6.. aroung there? Or will I have to make some epoxy casts..

-

bigbob12345

- Staff Sergeant

- Posts: 1516

- Joined: Sat Dec 01, 2007 9:13 am

- Location: Mercer Island,Washington

Sat Mar 22, 2008 9:52 pm

looks quite good so far

Well I prefer the good old marine epoxy but yes there are better things to use.

one thing though.

when i made my coax it wouldnt actuate with just the blowgun normally I had to mod it. But a 1/4in ball valve gives much higher performance than even a modded blowgun.

Its probably already been mentioned but what pressure do you plan on useing?

-

Counterstriker

- Specialist 4

- Posts: 426

- Joined: Tue May 29, 2007 2:06 pm

Sat Mar 22, 2008 10:38 pm

bigbob12345 wrote:looks quite good so far

Well I prefer the good old marine epoxy but yes there are better things to use.

one thing though.

when i made my coax it wouldnt actuate with just the blowgun normally I had to mod it. But a 1/4in ball valve gives much higher performance than even a modded blowgun.

Its probably already been mentioned but what pressure do you plan on useing?

Well.. I am guessing about.. 200 psi. I am buying a new 2 gallon compressor monday also with the rest of the pieces I need, (shrader, 3/4 reducer, 1/2 bushing and 3/8" pipe). But when you say a ball valve is faster, will the blowgun still be efficeint?

-

Counterstriker

- Specialist 4

- Posts: 426

- Joined: Tue May 29, 2007 2:06 pm

Sat Mar 22, 2008 11:12 pm

elitesniper wrote:that blow gun is the wrong way, you should swtich it to the 1/4 npt side the other side leaks.

Yah I know it will still work, I made a topic on why I did that. I was told it will still work to pretty much the same potential.

-

Counterstriker

- Specialist 4

- Posts: 426

- Joined: Tue May 29, 2007 2:06 pm

Mon Mar 24, 2008 4:50 pm

I had a change of plan. The piston will be in the 1/2" nipple (right next to the 1/2 tee). So the problem is the barrel will be long, I already cut it to right size, How can I stabalize a 3/8" barrel in a 3/4" chamber? (this is all steel, the barrel is copper).

Thanks!