Show us your pneumatic spud gun! Discuss pneumatic (compressed gas) powered potato guns and related accessories. Valve types, actuation, pipe, materials, fittings, compressors, safety, gas choices, and more.

-

jmeyer1022

- Specialist 2

- Posts: 200

- Joined: Sun Nov 09, 2008 4:50 pm

Mon Jan 12, 2009 2:29 pm

Alright so I've finally decided to work/finish this up.

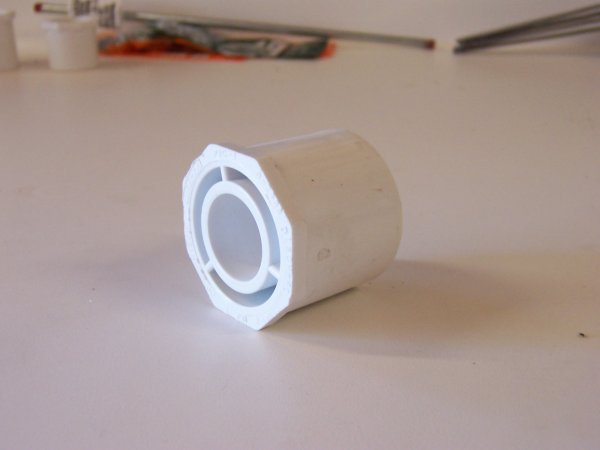

so far I have 1 1/2" pipe running through a dremelled 2-1 1/2 reducer

then going into the tee as pictured.

I then plan on running 2" pipe into the other side with a clean out as pictured

The piston I plan on doing will be 1 1/4" coupling filled with epoxy or glue and then the neoprene gasket on the front for a tight seal.

But my question is since the 2" side of the 2-1 1/2 reducer is into the tee with 1 1/2" pipe running through should I cut it so there's a short amount left then put another 2-1 1/2 reducer is its like back to back and then pop a 2" coupling on the 2" side of the reducer and place a clean out for interchangeable barrels?

If you need anymore info please let me know. thanks for your help

-

jrrdw

- Moderator

- Posts: 6572

- Joined: Wed Nov 16, 2005 5:11 pm

- Location: Maryland

- Has thanked: 39 times

- Been thanked: 22 times

-

Contact:

Mon Jan 12, 2009 2:40 pm

A better build would be to use a 2" coupler then a 2" flush bushing with a o-ring for sealing then adapter for the pilot valve. Clean out's aren't pressure rated if I remember correctly.

-

jmeyer1022

- Specialist 2

- Posts: 200

- Joined: Sun Nov 09, 2008 4:50 pm

Mon Jan 12, 2009 6:44 pm

jrrdw wrote:A better build would be to use a 2" coupler then a 2" flush bushing with a o-ring for sealing then adapter for the pilot valve. Clean out's aren't pressure rated if I remember correctly.

Sounds fine, I haven't see adapters at lowes/ home depot, but then again I really haven't looked for them before.

Would I just put a bunch of screws through instead of gluing, cause I want a housable piston in case it breaks. And for the O-ring would I just dremel a groove for it? Where can you buy O-rings that size? Once again thanks for the help.

-

ralphd

- Specialist

- Posts: 192

- Joined: Mon Dec 17, 2007 8:07 pm

- Location: Niles Ohio

Mon Jan 12, 2009 7:15 pm

My adapter looks like jmeyer1022's. It's made by Lasko and has "PW" on it. I was under the impression that stood for "Potable Water" so it's pressure rated........

-

iisthemuffin

- Specialist 4

- Posts: 497

- Joined: Sun May 11, 2008 2:38 pm

Mon Jan 12, 2009 7:54 pm

Its not pressure rated unless it has a rating on it. Its just made for use with pressure if it has PW on it. I have a clean out on my coaxial that is nsf-pw and its been holding up fine.

Poop.

-

jrrdw

- Moderator

- Posts: 6572

- Joined: Wed Nov 16, 2005 5:11 pm

- Location: Maryland

- Has thanked: 39 times

- Been thanked: 22 times

-

Contact:

Tue Jan 13, 2009 8:09 am

O-rings streach pretty good. I used 1 7/8ths for my 2" flush bushing. Check your local hardware stores, McMasters or do a Google search for the o-ring.

For cutting the groove, make a jig to mount it in a drill, lock the drill to on, place it in a vice to hold it still, then use your dremil to cut the groove. I would use a magic marker to make a guide line on the bushing, the cut ther groove, makes it easier to hold tight to a straight line.

You can probly use 6 screws to secure the bushing in your housing.

-

jmeyer1022

- Specialist 2

- Posts: 200

- Joined: Sun Nov 09, 2008 4:50 pm

Fri Jan 16, 2009 11:27 am

k so this is my unglued piston tee so far,

consists of a 2" tee with 1.5 porting 2" x 1.5" reducer dremeled so the pipe can slide through then another 2" x 1.5" reducer into a cleanout for interchangeable barrels. The other side of the tee is a 2" plug. My piston is a 1 1/4 coupling with rubber I still need to get a washer and epoxy to fill the coupling up a bit.

My question is will the pilot be big enough, if not should I just run a short piece of 2" pipe into the tee then a 2" coupling then my plug into the other side of the coupling or will this be fine. If you need any more info please let me know.

-

jrrdw

- Moderator

- Posts: 6572

- Joined: Wed Nov 16, 2005 5:11 pm

- Location: Maryland

- Has thanked: 39 times

- Been thanked: 22 times

-

Contact:

Fri Jan 16, 2009 2:57 pm

Your piston will need to slide back approx. .3145" , about 3/8ths of a inch. Measure everything including room for a bumper.

The piston should meet the barrel in the middle of the tee.

Are you filling the chamber from the pilot? Will you be adding a o-ring to your piston? Check valve?

A bolt and washer to hold the sealing face to the piston is a good plan. I have my washer big enough so it just fits inside the barrel, that way the sealing face don't get sucked out the barrel. Sealed the bolt with JB Weld.

Any questions feel free to ask.

-

jmeyer1022

- Specialist 2

- Posts: 200

- Joined: Sun Nov 09, 2008 4:50 pm

Fri Jan 16, 2009 5:54 pm

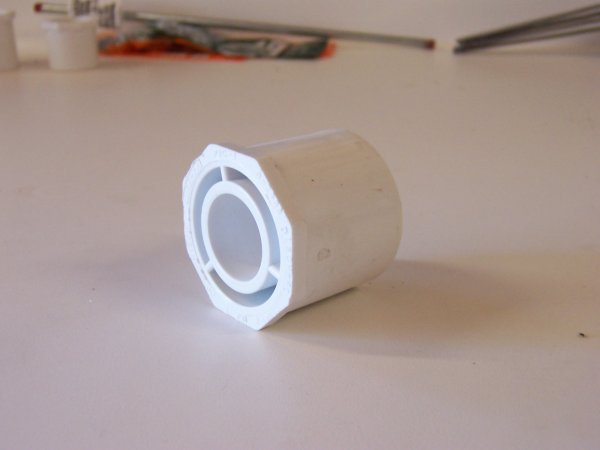

That's my finished piston. I will be filling from the pilot valve, I don't plan on adding an O-ring. What do you mean by a check valve? Also I see a lot of people talking about putting 2" pipe in as "guide pipe" so I'm thinking just putting the plug on the end would b kind of iffy. I have a lot of extra pipe/pieces hanging around so let me know what you think the best pilot setup is.

-

jrrdw

- Moderator

- Posts: 6572

- Joined: Wed Nov 16, 2005 5:11 pm

- Location: Maryland

- Has thanked: 39 times

- Been thanked: 22 times

-

Contact:

Fri Jan 16, 2009 7:34 pm

What do you mean by a check valve? Also I see a lot of people talking about putting 2" pipe in as "guide pipe" so I'm thinking just putting the plug on the end would b kind of iffy

A check valve is a one way valve designed to let air (or what ever) go through one way. In this case, it's a hole in the piston face just outside the barrel circumference but still under the rubber (sealing material) leading into the main air storage chamber. It allows for quicker filling and better performance.

When the pressure pushes the piston back, it also pushes the rubber against the hole sealing it up. If you where to use o-ring/s, you would need a check valve to let the air into the main chamber. O-rings make a positive seal for the pilot chamber.

As for the guide pipe, you need it for a smooth travel for the piston. All pistons should be matched with a cylinder.

-

jmeyer1022

- Specialist 2

- Posts: 200

- Joined: Sun Nov 09, 2008 4:50 pm

Mon Jan 19, 2009 4:20 pm

Ok, my Tee is all set up but I've been noticing my 1 1/4 coupling is sort of loose inside the 2" guide pipe it seals straight on perfectly but if i hold it at weird angles I don't think it will. Any ideas for a better piston?

-

jrrdw

- Moderator

- Posts: 6572

- Joined: Wed Nov 16, 2005 5:11 pm

- Location: Maryland

- Has thanked: 39 times

- Been thanked: 22 times

-

Contact:

Wed Jan 21, 2009 4:12 am

Some wrap a layer of duct tape around their pistons to adjust the clearance, or mold one out of hot glue, epoxy. I built mine out of wood, Oak.

-

jmeyer1022

- Specialist 2

- Posts: 200

- Joined: Sun Nov 09, 2008 4:50 pm

Wed Jan 21, 2009 4:52 pm

Ok so I really want to get this first try. I've been going through peoples tee valves, I know different but they all work.

The 2 I've been looking at mainly are Mr Crowley's and Unisonmind

http://www.spudfiles.com/forums/the-sta ... 10049.html

I was thinking of putting the 2 ideas together. Taking Unison's idea of the 1 1/2" reducer with threads with a piece of 1 1/4 coupler in it as the sealing face, then taking Mr Crowley's idea for the pilot by running 2" pipe into one side of the tee then into a female adapter with a threaded bushing into that as the pilot. I plan on looking around for more piston ideas due to not liking the 1 1/4 coupling.

EDIT: My dad found an O-ring kit so I'll be putting an O-ring on tomorrow.

Since the piston will be so tight inside the 2" pipe how will air get around it and fill the chamber since this is a barrel sealing piston. I'm guessing I'll have to add a check valve. I'll do more research and so on for this. Like I said I'm really looking to get this done first try.