Anyway, a rather elderly bolt holding the engine of our narrowboat to one of its main mountings has sheared off, leaving half the bolt thread in the tapped hole.

Because of the importance of the bolt in question, it's not a case of just leaving it - the remnants have to be removed, and it has to be replaced.

All of it has to come out, and with minimal damage to the surrounding engine.

I've got a set of bolt extractors handy, but I have very little experience with them. I wondered if anyone had any better suggestions or simply advice for dealing with the situation (both personal experience and sensible speculation are welcomed).

It's not really feasible to move the boat anywhere where the engine can be removed, because to do so, the engine would (obviously) need to be run, and so it has to be done in situ.

~~~~~

A picture of the now-sheared bolt, and the damage done around the hole (which is about 3mm deep). The mounting bracket has been removed here.

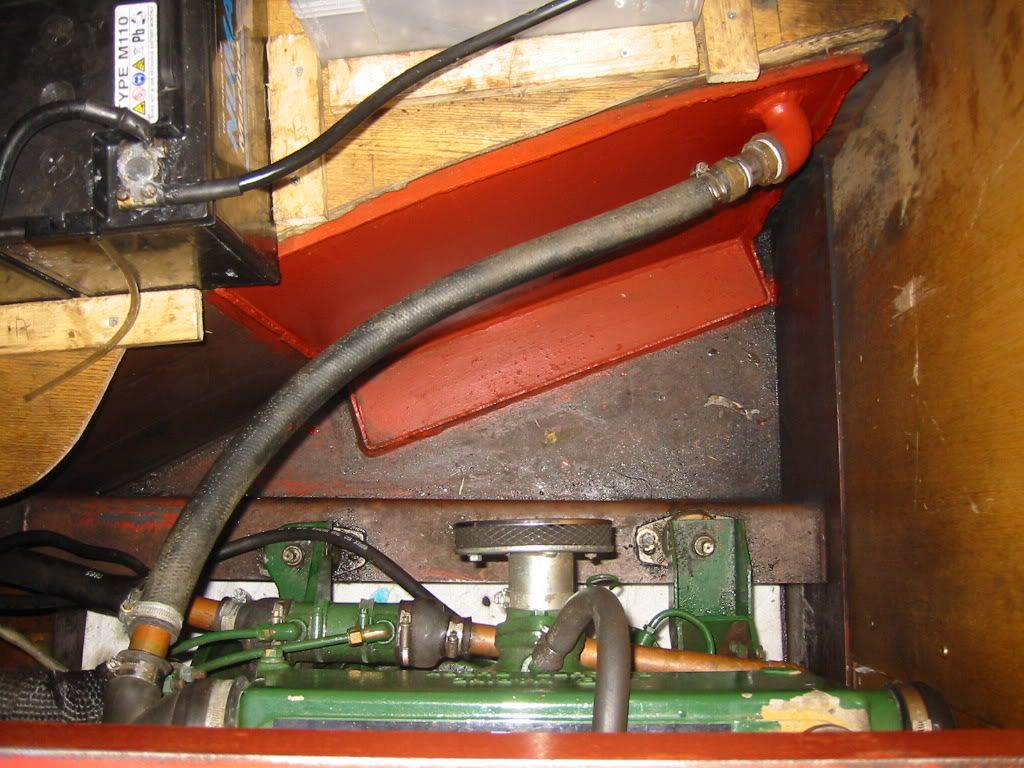

This picture is upside down, because the only meaningful way to get access to the area is by going head first (and down) into a relatively small space.

Best we know, this is a 3/8" UNF bolt, which makes little sense for what is essentially a marinised British Leyland engine - but that's what it seems to be, based on the dimensions and thread pitch and profile of the corresponding bolt from the other side of the engine.

~~~~~

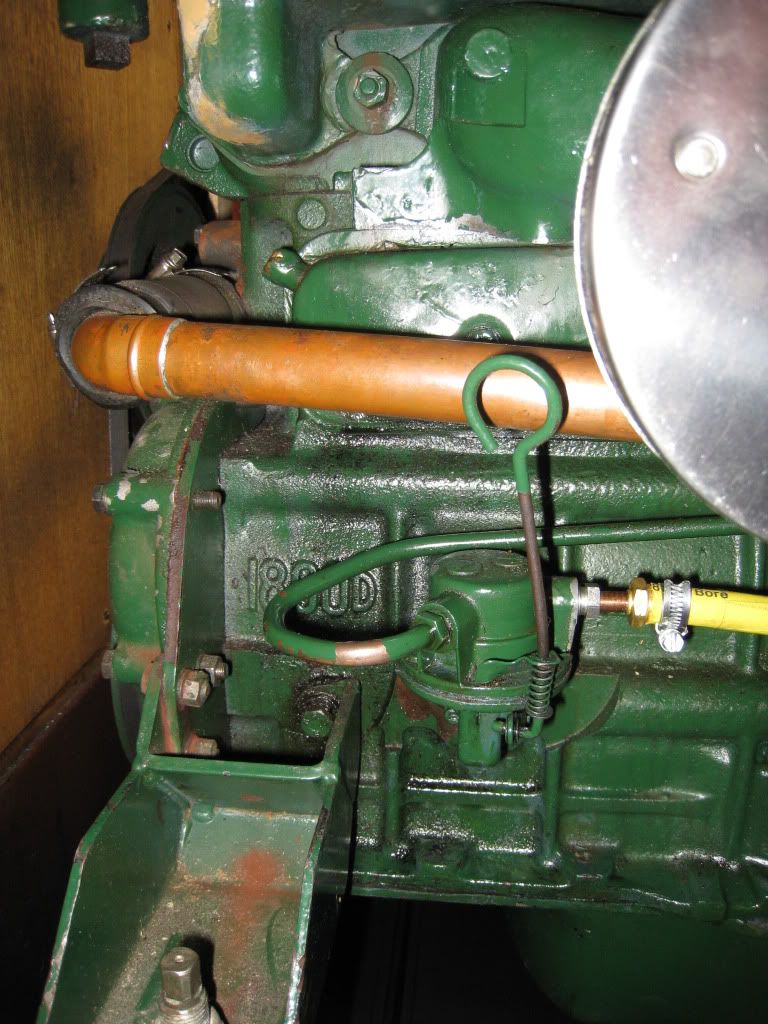

The bolt in question (prior to shearing) can be seen below the 00 in 1800 in this next picture. The limited space for the bolt head (within the mounting) means that it does not look feasible to re-tap the hole and use a larger bolt (although a Heli-coil has been considered, and not completely ruled out - but it is less than ideal).

Bear in mind, the object to the right of the 1800D marking is the main fuel pump and feed from the diesel tank. It can't feasibly be moved, nor is any situation where it is at risk of damage acceptable.

~~~~~

And to illustrate the limited space which I'll have to be upside down in to work. There's next to no space for anything but modestly sized power tools.

The foot in question is on the right in this image (next to the air intake filter)

~~~~~

The current plan, unless I am advised otherwise, is to drill into the bolt with first a 3mm pilot hole using a Dremel.

This will then be increased to a 4mm hole with a larger drill. It may then be increased to 4.5mm if everything remains favourable.

The bolt extractor will be inserted then, with luck, use of a tap wrench will extract the bolt. As it's not under load, the hope is that it will be relatively free moving. However, knowing this engine, it will likely be at least partly jammed in place.

If it is jammed, the plan is to then feed penetrating oil through the hole in the bolt (as I know there to be at least 5mm of space behind the back of the bolt) to settle there for a while, and hopefully free up the bolt.

If it comes out, then the plan is to then assess the thread. If it's damaged, then I'll be re-tapping the thread with a 3/8" UNF tap. If it appears good, or after the thread is improved, the mounting bracket will be replaced, and the various nuts put back into place.

~~~~~

Anyway, if you can see flaws in that plan, or have suggestions or advice, I'd like to hear about it.

If you have a better idea that may prove within the bounds of possibility, that'll do too.

If you do have any suggestions, please make sure they're not vague, because I'll only have time to briefly check this topic before heading down there tomorrow to attempt to extract, and I won't be able to hang around asking "What do you mean?"