Sheared bolt extraction?

Oops - I thought I'd said that, but apparently I hadn't.

It wasn't torqued off.

It was somewhat old, and sheared/snapped off in operation. Fortunately, there are other bolts on that mount (so the engine didn't simply break loose) and we were able to rig it up with other support so that we could run the fortunately short distance back to the boat's home mooring.

However, that was a incredibly temporary set up, and we cannot feasibly move the boat any further (on the engine at least) without fixing this bolt.

Anyway, I don't know precisely how it failed, but torque wasn't being applied at the time.

The fact it failed in such a fashion is pretty much the reason I think the remaining threads will be seriously buggered up - at least beyond the limits where the bolt will come out completely freely.

It wasn't torqued off.

It was somewhat old, and sheared/snapped off in operation. Fortunately, there are other bolts on that mount (so the engine didn't simply break loose) and we were able to rig it up with other support so that we could run the fortunately short distance back to the boat's home mooring.

However, that was a incredibly temporary set up, and we cannot feasibly move the boat any further (on the engine at least) without fixing this bolt.

Anyway, I don't know precisely how it failed, but torque wasn't being applied at the time.

The fact it failed in such a fashion is pretty much the reason I think the remaining threads will be seriously buggered up - at least beyond the limits where the bolt will come out completely freely.

Does that thing kinda look like a big cat to you?

- Technician1002

- Captain

- Posts: 5189

- Joined: Sat Apr 04, 2009 11:10 am

A trick I've seen done on a stuck bolt is to take a thermos and fill it with chunks of dry ice and then fill it 1/2 way with rubbing alcohol, then replenish to the top with dry ice again and top off with alcohol.

After drilling a hole into the bolt but before inserting the extractor, use a tube and funnel to pour the alcohol into the bolt, shrinking it slightly and then quickly using the extractor. Use a pan of water under the drip to catch the alcohol and dilute it below the flash point. This can be used to remove some stubborn bolts. Be aware the hardened extractor will be more brittle at the cold temperature.

For bolt ID, the manufacturer's marks are the letters and the bevel on the edge of the head identifies it as;

A-354-BD

A490 Med. Carbon

alloy steel

Quenched &

tempered

150,000 p.s.i.

This is a relatively stout bolt with some malleability and not too brittle.

After drilling a hole into the bolt but before inserting the extractor, use a tube and funnel to pour the alcohol into the bolt, shrinking it slightly and then quickly using the extractor. Use a pan of water under the drip to catch the alcohol and dilute it below the flash point. This can be used to remove some stubborn bolts. Be aware the hardened extractor will be more brittle at the cold temperature.

For bolt ID, the manufacturer's marks are the letters and the bevel on the edge of the head identifies it as;

A-354-BD

A490 Med. Carbon

alloy steel

Quenched &

tempered

150,000 p.s.i.

This is a relatively stout bolt with some malleability and not too brittle.

- jimmy101

- Sergeant Major 2

- Posts: 3210

- Joined: Wed Mar 28, 2007 9:48 am

- Location: Greenwood, Indiana

- Has thanked: 6 times

- Been thanked: 18 times

- Contact:

My $0.02

Put the penetrating oil on and let it sit as long as you possible can. A couple days would be good. You can just tape a rag saturated with the oil over the bolt, cover that with plastic wrap, and tape the whole mess in place.

Periodically give it a tap. The vibration helps the oil penetrate.

Sometimes the counter intuitive thing is the best thing. The first problem is to get the thing to move at all. Doesn't matter much which way it moves, in or out. (Of course, you don't want to crank it in any farther than you have to.) Once it moves you've broken the corrosion weld.

So, if you drill you don't need a reverse bit. It actually would be good if the bolt started to rotate some with the bit.

Not sure if I'm reading the setup correctly but it looks to me like there is no tension or compressive load on the bolt anymore? So it shouldn't matter which way it turns initially since there isn't anything to get drawn tighter.

A torch would really help but that doesn't sound like a good idea. Liquid N2 or dry ice is possible if you can get. Basically you are trying to do is get a bit of difference in temp between the two parts. The differential expansion generates immense forces and will often break loose the corosion layer between the two parts. Another possiblity for heat in the cramped quarters is a big ass soldering iron. One of those old Weller types perhaps? Heat also benefits with a couple day presoak with penetrating oil.

My experience with extractors has been kind of hit or miss. The hard part is getting a decent pilot hole that is centered. I've had some luck with what others haves suggested, driving a screwdriver into the bolt fragment. But, if you drive it in too much then you expand the end of the bolt and may jam it permanently. You might consider an impact wrench with a sharpend (and expendable) flat blade screwdriver tip. This oftens works great since it drives the blade in at the same time it tries to turn. Also the vibration of hitting the impact wrench with the hammer sets up a nice vibration exactly when you need it most. Not sure if you have the space to get a hammer in there.

Good luck.

Put the penetrating oil on and let it sit as long as you possible can. A couple days would be good. You can just tape a rag saturated with the oil over the bolt, cover that with plastic wrap, and tape the whole mess in place.

Periodically give it a tap. The vibration helps the oil penetrate.

Sometimes the counter intuitive thing is the best thing. The first problem is to get the thing to move at all. Doesn't matter much which way it moves, in or out. (Of course, you don't want to crank it in any farther than you have to.) Once it moves you've broken the corrosion weld.

So, if you drill you don't need a reverse bit. It actually would be good if the bolt started to rotate some with the bit.

Not sure if I'm reading the setup correctly but it looks to me like there is no tension or compressive load on the bolt anymore? So it shouldn't matter which way it turns initially since there isn't anything to get drawn tighter.

A torch would really help but that doesn't sound like a good idea. Liquid N2 or dry ice is possible if you can get. Basically you are trying to do is get a bit of difference in temp between the two parts. The differential expansion generates immense forces and will often break loose the corosion layer between the two parts. Another possiblity for heat in the cramped quarters is a big ass soldering iron. One of those old Weller types perhaps? Heat also benefits with a couple day presoak with penetrating oil.

My experience with extractors has been kind of hit or miss. The hard part is getting a decent pilot hole that is centered. I've had some luck with what others haves suggested, driving a screwdriver into the bolt fragment. But, if you drive it in too much then you expand the end of the bolt and may jam it permanently. You might consider an impact wrench with a sharpend (and expendable) flat blade screwdriver tip. This oftens works great since it drives the blade in at the same time it tries to turn. Also the vibration of hitting the impact wrench with the hammer sets up a nice vibration exactly when you need it most. Not sure if you have the space to get a hammer in there.

Good luck.

- Technician1002

- Captain

- Posts: 5189

- Joined: Sat Apr 04, 2009 11:10 am

A trick I have used that works well is to use a magnet mount from a mag mount CB antenna and use it to center a drill guide tube. The magnet is strong enough to prevent much creep while starting the pilot hole.My experience with extractors has been kind of hit or miss. The hard part is getting a decent pilot hole that is centered.

Drill through the mount with a drillpress to create a hole starting jig. Measure off the hole center and mark it on the block with a sharpie and then mount and center the jig. Watch for the jig to creep when drilling.

Sometimes you can find a broken antenna in Goodwill for a cheap magnet.

And the answer is:

It was little interesting to do, aside from the fact ALL the work had to be done while hung upside down.

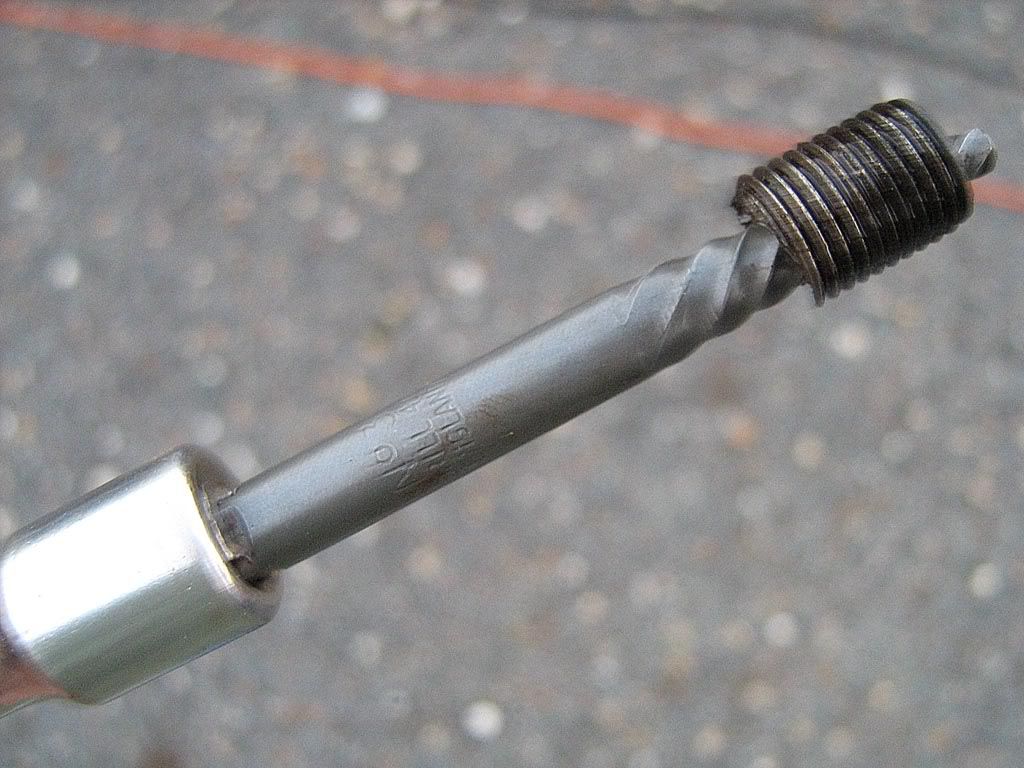

Firstly the centre punch decided to jump when I first set it in place because the end of the bolt was on a slant:

You can see that first dent half hidden behind a second attempt I really only got because of the insane capacities of Dremels.

To be entirely honest, I doubt the job would have been possible without the Dremel. It went down through the bolt like a hot knife through butter - although it annihilated a drill bit in the process.

You can probably tell that the hole wasn't perfect from the first picture, but you try drilling a perfect hole while you're upside down, on a boat that's rocking around and you've got next to no reference for vertical.

Anyway, it was good enough.

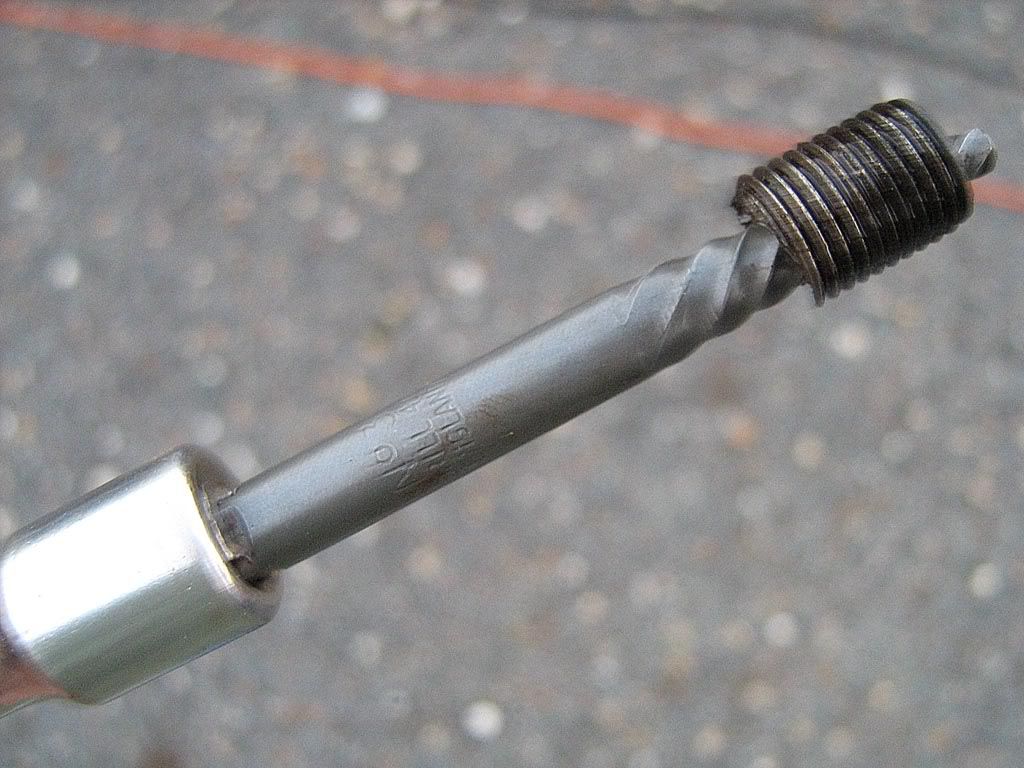

The Dremel also proved a lifesaver when it became clear that there was not the space to swing the tap wrench. One washer and a few cuts later, and I had a temporary adaptor that allowed it to fit into a 1/4" socket extension, which could then fit into the tap wrench and allow it to be driven from 4" further back, allowing it the space necessary:

I should note, not a sign of it shifting until the extractor and quite a bit of torque was applied. Certainly no movement while drilling it.

So anyway, job done. Here's hoping it's a long time until I have to do such a demanding, cramped and physically unpleasant task again.

It was little interesting to do, aside from the fact ALL the work had to be done while hung upside down.

Firstly the centre punch decided to jump when I first set it in place because the end of the bolt was on a slant:

You can see that first dent half hidden behind a second attempt I really only got because of the insane capacities of Dremels.

To be entirely honest, I doubt the job would have been possible without the Dremel. It went down through the bolt like a hot knife through butter - although it annihilated a drill bit in the process.

You can probably tell that the hole wasn't perfect from the first picture, but you try drilling a perfect hole while you're upside down, on a boat that's rocking around and you've got next to no reference for vertical.

Anyway, it was good enough.

The Dremel also proved a lifesaver when it became clear that there was not the space to swing the tap wrench. One washer and a few cuts later, and I had a temporary adaptor that allowed it to fit into a 1/4" socket extension, which could then fit into the tap wrench and allow it to be driven from 4" further back, allowing it the space necessary:

I should note, not a sign of it shifting until the extractor and quite a bit of torque was applied. Certainly no movement while drilling it.

So anyway, job done. Here's hoping it's a long time until I have to do such a demanding, cramped and physically unpleasant task again.

Does that thing kinda look like a big cat to you?

-

THUNDERLORD

- Sergeant 3

- Posts: 1264

- Joined: Fri Mar 28, 2008 1:42 pm

Good job!!!

Although it may have been luck since:

Reminds me of a mixed drink a seasoned homeless guy was telling me about called " FOUR FIFTY ONE" ...a mixture of bacardi 151, everclear 190 proof, beer(?) and distilled lighter fluid...

Anyhow, Ragnarok, the "duck in a bucket" pic made me LOL,

And the boat pics cheered me up too, looks like a fun/ nice boat.

Maybe some day, you'll appreciate it more(?)...

Good job on the bolt, thanks for the pics too. 8) 8)

Although it may have been luck since:

You Should've used a monkey wrench (duh!!!)...until I have to do such a demanding, cramped and physically unpleasant task again....

Geez O' Flip!!!...fill it with chunks of dry ice and then fill it 1/2 way with rubbing alcohol, then replenish to the top with dry ice again and top off with alcohol.

After drilling a hole into the bolt but before inserting the extractor, use a tube and funnel to pour the alcohol into the bolt, shrinking it slightly...

Reminds me of a mixed drink a seasoned homeless guy was telling me about called " FOUR FIFTY ONE" ...a mixture of bacardi 151, everclear 190 proof, beer(?) and distilled lighter fluid...

Anyhow, Ragnarok, the "duck in a bucket" pic made me LOL,

And the boat pics cheered me up too, looks like a fun/ nice boat.

Maybe some day, you'll appreciate it more(?)...

Good job on the bolt, thanks for the pics too. 8) 8)

-----SPEED,STRENGTH, AND ACCURACY.-----

"Procrastination" is five syllables for "Sloth".

Theopia 8)

Born To Be Alive!

"Procrastination" is five syllables for "Sloth".

Theopia 8)

Born To Be Alive!

I don't OWN a monkey wrench.THUNDERLORD wrote:You should've used a monkey wrench (duh!!!)

Bloody clumsy, ugly and heavy things. There wouldn't've been the space to swing one.

It was a truly bizarre experience, managing to fish a duck out of the water and into the bucket. It attracted a pretty sizeable audience.Anyhow, Ragnarok, the "duck in a bucket" pic made me LOL

I seem to get involved in a lot of "rescues". Rescuing a lost duck, an aground boat, an adrift boat, or just simply hauling 15 tonnes of boat back out of the fastest flowing section on the non-tidal Thames.

Oh, I do appreciate it. It's just very odd, and can take a lot of effort at times.And the boat pics cheered me up too, looks like a fun/nice boat. Maybe some day, you'll appreciate it more(?)...

But fun? Depends on who you ask. My brother can't live with only moving at 3 to 4 miles an hour (although we've had 6 mph on wide rivers - much of what limits speed is the narrow channel of canals).

Does that thing kinda look like a big cat to you?

No, the main limitation on speed is the fact that the engine pulls water out from under the boat, making it sit lower in the water when it's moving (at least in a relatively shallow channel) and increasing fluid drag.jrrdw wrote:Put a trim tab on it, that will help get some more speed out of her.

The more power you try applying, the lower it sits. So unless you apply power in some other fashion, that's about it.

Appropriately, 4 mph is also pretty much the speed limit set many of Britain's inland waterways - seldom enforced though.

Does that thing kinda look like a big cat to you?

- jrrdw

- Moderator

- Posts: 6572

- Joined: Wed Nov 16, 2005 5:11 pm

- Location: Maryland

- Has thanked: 39 times

- Been thanked: 22 times

- Contact:

Well the trim tab is what gets the boat up out of the water thus less drag and more speed. But from what you just said this boat is driven by a jet pump, like a wave runner. A trim tab would still help but no where near as much as if it was prop driven.

I've helped rebuild a few wave runners in my time. The up grades where opening the water intake, (rebuild the hull). Rebuild or replace the engine, and install a progressive impeller.

Me and my friend Danny took a 35 knot SeaDoo and made it run 82 knots. It scared him so he sold it!

I've helped rebuild a few wave runners in my time. The up grades where opening the water intake, (rebuild the hull). Rebuild or replace the engine, and install a progressive impeller.

Me and my friend Danny took a 35 knot SeaDoo and made it run 82 knots. It scared him so he sold it!

- Technician1002

- Captain

- Posts: 5189

- Joined: Sat Apr 04, 2009 11:10 am

That only works for planing hulls. Rounded displacement hulls are simply the wrong shape for that, They have a "Hull Speed" at which they go a little faster, dig a big hole in the water and fall in deeper plowing more water. Doubling the power gains you very little speed.jrrdw wrote:Put a trim tab on it, that will help get some more speed out of her.

My sailboat has about a 5 knot hull speed.

http://en.wikipedia.org/wiki/Hull_speed

This page shows the plowing and dropping of a boat from excessive speed. Trim tabs won't fix this.

- D_Hall

- Staff Sergeant 5

- Posts: 1946

- Joined: Thu Feb 07, 2008 7:37 pm

- Location: SoCal

- Has thanked: 11 times

- Been thanked: 44 times

I beg to differ! But like so many things, they should only be used when the job calls for it (right tool for the right job and all that). They positively excel when you need a very large wrench (for me, that means 2-3 inches) but don't have the space to bring in a massive "crescent" wrench (yes, I know that crescent is a brand name). For whatever reason, monkey wrenches tend to have shorter handles....Ragnarok wrote:I don't OWN a monkey wrench.THUNDERLORD wrote:You should've used a monkey wrench (duh!!!)

Bloody clumsy, ugly and heavy things. There wouldn't've been the space to swing one.

(Yes, I own a monkey wrench... Although I concede it's probably an antique, it works beautifully.)

- Technician1002

- Captain

- Posts: 5189

- Joined: Sat Apr 04, 2009 11:10 am

I wonder how many young users on SF know the difference between a pipe wrench and a monkey wrench. The latter is getting harder to find nowdays.

A guy in the Navy built a left handed monkey wrench as a joke as he was so often sent to get one. Now he could deliver one. It has left hand threads on the adjusting screw.

http://en.wikipedia.org/wiki/Monkey_wrench

The most differentiation is which jaw adjusts. The monkey wrench the upper jaw and handle are one piece with a lower adjustable jaw. In a pipe wrench the handle and lower jaw are one solid piece with an adjustable upper jaw. Style and construction vary.

Laughing out loud, wikipedia has a photograph of a left handed monkey wrench. Note the adjusting screw is left hand thread.

A guy in the Navy built a left handed monkey wrench as a joke as he was so often sent to get one. Now he could deliver one. It has left hand threads on the adjusting screw.

http://en.wikipedia.org/wiki/Monkey_wrench

The most differentiation is which jaw adjusts. The monkey wrench the upper jaw and handle are one piece with a lower adjustable jaw. In a pipe wrench the handle and lower jaw are one solid piece with an adjustable upper jaw. Style and construction vary.

Laughing out loud, wikipedia has a photograph of a left handed monkey wrench. Note the adjusting screw is left hand thread.

Last edited by Technician1002 on Sun Sep 13, 2009 1:19 am, edited 1 time in total.

- D_Hall

- Staff Sergeant 5

- Posts: 1946

- Joined: Thu Feb 07, 2008 7:37 pm

- Location: SoCal

- Has thanked: 11 times

- Been thanked: 44 times

In addition...Technician1002 wrote:The most differentiation is which jaw adjusts. The monkey wrench the upper jaw and handle are one piece with a lower adjustable jaw. In a pipe wrench the handle and lower jaw are one solid piece with an adjustable upper jaw. Style and construction vary.

Pipe wrenches have teeth on their jaws. Monkey wrenches don't (or at least, I've never seen one that did).

- jrrdw

- Moderator

- Posts: 6572

- Joined: Wed Nov 16, 2005 5:11 pm

- Location: Maryland

- Has thanked: 39 times

- Been thanked: 22 times

- Contact:

I totally disagree, the boat isn't sinking deeper in to the water because of more speed. The water is just being pushed away further giving the illusion the boat is sinking. A trim tab will help any boat plane higher in the water when adjusted to the proper pitch.Technician1002 wrote:That only works for planing hulls. Rounded displacement hulls are simply the wrong shape for that, They have a "Hull Speed" at which they go a little faster, dig a big hole in the water and fall in deeper plowing more water. Doubling the power gains you very little speed.jrrdw wrote:Put a trim tab on it, that will help get some more speed out of her.

My sailboat has about a 5 knot hull speed.

http://en.wikipedia.org/wiki/Hull_speed

This page shows the plowing and dropping of a boat from excessive speed. Trim tabs won't fix this.

The picture in the Wiki link you posted tells the story by it's self. Look at the very front of the ship in the top picture and compare it to the bottom picture. Both pictures show the hull the same depth.

The difference is in the size of the wave. The back of the boat will squat until the ship reaches it's speed then it will plane out until a speed change happens, at witch time it will either raise up (the ship has slowed down) or sink (the ship has speed-ed up, but then will again plane out once speed has been reached).