Al/H2O Reactions

I don't know of any dielectric material that could survive this kind of loading without lots of support from a metal casing. The solution is a better casing design for the insulator. In this case, what happened was kind of a cascading shear failure - it was only shearing at the point where it met the endplate. The solution is to get rid of the gap that the excess material escapes through. By adding a steel "ring" (more like a tube) that blocks the end of the insulator and having the wide part of the insulator terminate just inside the casing, as opposed to directly against the endplate, the problem will be solved. After that modification, the entire insulator would have to shear at once, a process that would require ~210kpsi chamber pressure, a similar number to the ~190kpsi required to rip all the threads out at once. It will make the insulator longer, but I can currently tap continuous, high quality threads up to 5" deep in plastics, so this shouldn't be a problem.What are your options(material wise) for creating an insulator that doesn't deform under pressure so badly?

I imagine ceramic wouldn't take the shock load, but I don't know of many plastics that would suffice. Maybe garolite or similar?

In fact, figuring out how to contain insulators at extreme pressure has been one of the more challenging parts of the electric launcher design work over the past years. I'd say I've figured out how to prevent all possible failure modes now and that it won't happen again, but I've said that too many times before...

Because the terminals were thrown together at the last minute, and a few nanohenries more inductance won't make a whole lot of difference to the horrible system geometry that's already in place.In the 3rd picture why not put a half twist on the copper and bolt it directly to the lug?

Also, we need to come up with some better ideas for loading the propellant mix. Packing all that foil in takes over an hour, is horribly tedious, and can be ruined by one slip at any point in the procedure.

Spudfiles' resident expert on all things that sail through the air at improbable speeds, trailing an incandescent wake of ionized air, dissociated polymers and metal oxides.

So are ceramics off the table for use as insulators?

Is it possible to use a syringe to load the slurry?

Is it possible to use a syringe to load the slurry?

Using machinable ceramics introduces manufacturing difficulties that I'm not interested in getting involved with, and is tremendously expensive, considering that an ETG/aluminum-water gun which uses the same insulator for multiples shots is starting to look like a pipe dream. If it ever looks like a long lifespan insulator is coming within reach, I'll consider ceramics again. Currently, I'm happy paying $2/shot rather than $20...So are ceramics off the table for use as insulators?

The syringe isn't a bad idea, but the mix I'm using is far too aluminum-rich for that. This is compounded by the relatively large aluminum foil chunks. The events of 2008 mean that I'll never keep powdered aluminum around any more, so I'm stuck with the foil chunks for now. It's tempting to try unthreading the cathode halfway, filling with water, dumping the aluminum in and then threading it back in while packing the mix down, but I could see losing a lot of water that way.

Ah, lots of interesting experimentation to plan for the summer...

Spudfiles' resident expert on all things that sail through the air at improbable speeds, trailing an incandescent wake of ionized air, dissociated polymers and metal oxides.

You could probably prepare just enough aluminium powder for each shot by using a burr grinder or a ball mill.

Add more water to the mix, then let the aluminium settle out and draw out the excess? There'll be some large measurement error in there, but extra water shouldn't hurt too much, should it?

Add more water to the mix, then let the aluminium settle out and draw out the excess? There'll be some large measurement error in there, but extra water shouldn't hurt too much, should it?

- Crna Legija

- First Sergeant 2

- Posts: 2333

- Joined: Sun Jul 20, 2008 5:14 am

- Location: australia

what if you use a coffey bean grinder to cut up the foil then drill the end of a syringe out to let it flow better.

'' To alcohol... The cause of, and solution to, all of life's problems.”

--Homer Simpson

Add me on ps3: wannafuk, 8/11/11 cant wait

--Homer Simpson

Add me on ps3: wannafuk, 8/11/11 cant wait

-

SpudBlaster15

- First Sergeant 3

- Posts: 2400

- Joined: Wed Oct 18, 2006 11:12 pm

- Has thanked: 2 times

- Been thanked: 10 times

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Cras nec placerat erat. Vivamus dapibus egestas nunc, at eleifend neque. Suspendisse potenti. Sed dictum lacus eu nisl pretium vehicula. Ut faucibus hendrerit nisi. Integer ultricies orci eu ultrices malesuada. Fusce id mauris risus. Suspendisse finibus ligula et nisl rutrum efficitur. Vestibulum posuere erat pellentesque ornare venenatis. Integer commodo fermentum tortor in pharetra. Proin scelerisque consectetur posuere. Vestibulum molestie augue ac nibh feugiat scelerisque. Sed aliquet a nunc in mattis.

Last edited by SpudBlaster15 on Thu Jul 15, 2021 12:35 am, edited 1 time in total.

- Crna Legija

- First Sergeant 2

- Posts: 2333

- Joined: Sun Jul 20, 2008 5:14 am

- Location: australia

using sand paper you might end up with contaminates in the alu dust.

'' To alcohol... The cause of, and solution to, all of life's problems.”

--Homer Simpson

Add me on ps3: wannafuk, 8/11/11 cant wait

--Homer Simpson

Add me on ps3: wannafuk, 8/11/11 cant wait

-

SpudBlaster15

- First Sergeant 3

- Posts: 2400

- Joined: Wed Oct 18, 2006 11:12 pm

- Has thanked: 2 times

- Been thanked: 10 times

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Cras nec placerat erat. Vivamus dapibus egestas nunc, at eleifend neque. Suspendisse potenti. Sed dictum lacus eu nisl pretium vehicula. Ut faucibus hendrerit nisi. Integer ultricies orci eu ultrices malesuada. Fusce id mauris risus. Suspendisse finibus ligula et nisl rutrum efficitur. Vestibulum posuere erat pellentesque ornare venenatis. Integer commodo fermentum tortor in pharetra. Proin scelerisque consectetur posuere. Vestibulum molestie augue ac nibh feugiat scelerisque. Sed aliquet a nunc in mattis.

Last edited by SpudBlaster15 on Thu Jul 15, 2021 12:35 am, edited 1 time in total.

Would simply replacing the Al with Mg offer any benefits? Or does the oxide layer of MgO offset any benefits?

Using a fine file to produce the powder wouldn't produce any contaminants, and the particulate produced thus is fine enough to facilitate very fast oxidation.

Using a fine file to produce the powder wouldn't produce any contaminants, and the particulate produced thus is fine enough to facilitate very fast oxidation.

-

SpudBlaster15

- First Sergeant 3

- Posts: 2400

- Joined: Wed Oct 18, 2006 11:12 pm

- Has thanked: 2 times

- Been thanked: 10 times

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Cras nec placerat erat. Vivamus dapibus egestas nunc, at eleifend neque. Suspendisse potenti. Sed dictum lacus eu nisl pretium vehicula. Ut faucibus hendrerit nisi. Integer ultricies orci eu ultrices malesuada. Fusce id mauris risus. Suspendisse finibus ligula et nisl rutrum efficitur. Vestibulum posuere erat pellentesque ornare venenatis. Integer commodo fermentum tortor in pharetra. Proin scelerisque consectetur posuere. Vestibulum molestie augue ac nibh feugiat scelerisque. Sed aliquet a nunc in mattis.

Last edited by SpudBlaster15 on Thu Jul 15, 2021 12:35 am, edited 1 time in total.

Interesting. I wasn't aware there were such drastic differences in the oxide coatings on highly reactive metals.

So I can see that stearic acid (which if you had used the IUPAC name would have really helped ) is a liquid hydrocarbon, so is it employed like mineral oil? Wouldn't the nonpolar coating then interfere with the reaction with water?

) is a liquid hydrocarbon, so is it employed like mineral oil? Wouldn't the nonpolar coating then interfere with the reaction with water?

How does the Potassium chromate work? Does it react with or plate onto the particles?

Sorry this is so far off topic, but I'm really curious

So I can see that stearic acid (which if you had used the IUPAC name would have really helped

How does the Potassium chromate work? Does it react with or plate onto the particles?

Sorry this is so far off topic, but I'm really curious

-

SpudBlaster15

- First Sergeant 3

- Posts: 2400

- Joined: Wed Oct 18, 2006 11:12 pm

- Has thanked: 2 times

- Been thanked: 10 times

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Cras nec placerat erat. Vivamus dapibus egestas nunc, at eleifend neque. Suspendisse potenti. Sed dictum lacus eu nisl pretium vehicula. Ut faucibus hendrerit nisi. Integer ultricies orci eu ultrices malesuada. Fusce id mauris risus. Suspendisse finibus ligula et nisl rutrum efficitur. Vestibulum posuere erat pellentesque ornare venenatis. Integer commodo fermentum tortor in pharetra. Proin scelerisque consectetur posuere. Vestibulum molestie augue ac nibh feugiat scelerisque. Sed aliquet a nunc in mattis.

Last edited by SpudBlaster15 on Thu Jul 15, 2021 12:33 am, edited 1 time in total.

The upgraded version of the launcher shown on the first page, which is considerably more likely to hold together as well as easier to load, is now within a few hours of completion, scheduled for a test firing late tomorrow at 5kJ. This new version is 1/4" bore, and will be tested with lightweight rounds to determine the feasibility of the reaction in question for high speed launch.

The overall speed of sound in the chamber gases post-ignition will be between 600m/s and 1000m/s, owing to the very low SOS in gaseous Al<sub>2</sub>O<sub>3</sub>. This does not bode well for the high speed side of things, and assuming that the gases remain in their initial mixed state throughout the working volume during the firing process, the reaction by itself will be shown to be largely useless for my purposes (there's still the possibility of using it as a heat source for vaporising other propellants).

There is, of course, another possibility which drove the consideration of this concept in the first place. The hydrogen molecules (and atoms) here are small and very fast moving, with a SOS in the hydrogen the reaction produces of about 5000m/s. In this case, I think it possible that as the round accelerates up to the sound speed in the mix the volume behind it may rapidly gain hydrogen concentration, causing a much higher effective SOS in the propellant gas than one would expect. Whether this will be sufficient to offset the terrible properties of the aluminum oxide should be seen very soon. Watch this space.

The overall speed of sound in the chamber gases post-ignition will be between 600m/s and 1000m/s, owing to the very low SOS in gaseous Al<sub>2</sub>O<sub>3</sub>. This does not bode well for the high speed side of things, and assuming that the gases remain in their initial mixed state throughout the working volume during the firing process, the reaction by itself will be shown to be largely useless for my purposes (there's still the possibility of using it as a heat source for vaporising other propellants).

There is, of course, another possibility which drove the consideration of this concept in the first place. The hydrogen molecules (and atoms) here are small and very fast moving, with a SOS in the hydrogen the reaction produces of about 5000m/s. In this case, I think it possible that as the round accelerates up to the sound speed in the mix the volume behind it may rapidly gain hydrogen concentration, causing a much higher effective SOS in the propellant gas than one would expect. Whether this will be sufficient to offset the terrible properties of the aluminum oxide should be seen very soon. Watch this space.

Spudfiles' resident expert on all things that sail through the air at improbable speeds, trailing an incandescent wake of ionized air, dissociated polymers and metal oxides.

The short version of the results of last night's test is that the reaction is capable of high speed launch, but not with any great efficiency. The test was conducted at 5.8kJ energy input (15.5kV on my bank) with 1g of Al/H<sub>2</sub>O mix , and apart from a curious sporadic discharge of a few joules (into what I don't yet know...) during the charging process, went smoothly. The best news to come out of this is that, after two years of fiddling with it, I have finally developed a chamber which can contain discharges at these energies with NO failure

The insulator is so well confined in this new design that there was no change in chamber volume, not even the slightest gas leakage, and no noticeable insulator damage at all after being exposed to gas at ~6000K and 100kpsi, apart from the expected ablation, melting, and subsequent collapse of the inner wall. The only factor discouraging reuse of the insulator is the deformation required during the assembly process to achieve the seal and the aforementioned ablation which is, of course, completely unavoidable without moving to ceramics.

I aim to machine two more insulators and conduct at least one more test today, against an aluminum target instead of the plasticine block (I feared that if the reaction had turned out to be totally useless there would be no damage at all to the aluminum target and thus nothing to judge velocity by). The ejection of a significant quantity of unburned fuel in last night's test points up the need for a stronger rupture diaphragm when using lightweight rounds (no such behavior was detected when testing with a heavy round on the last break from school), and somewhat obscures the results of the impact.

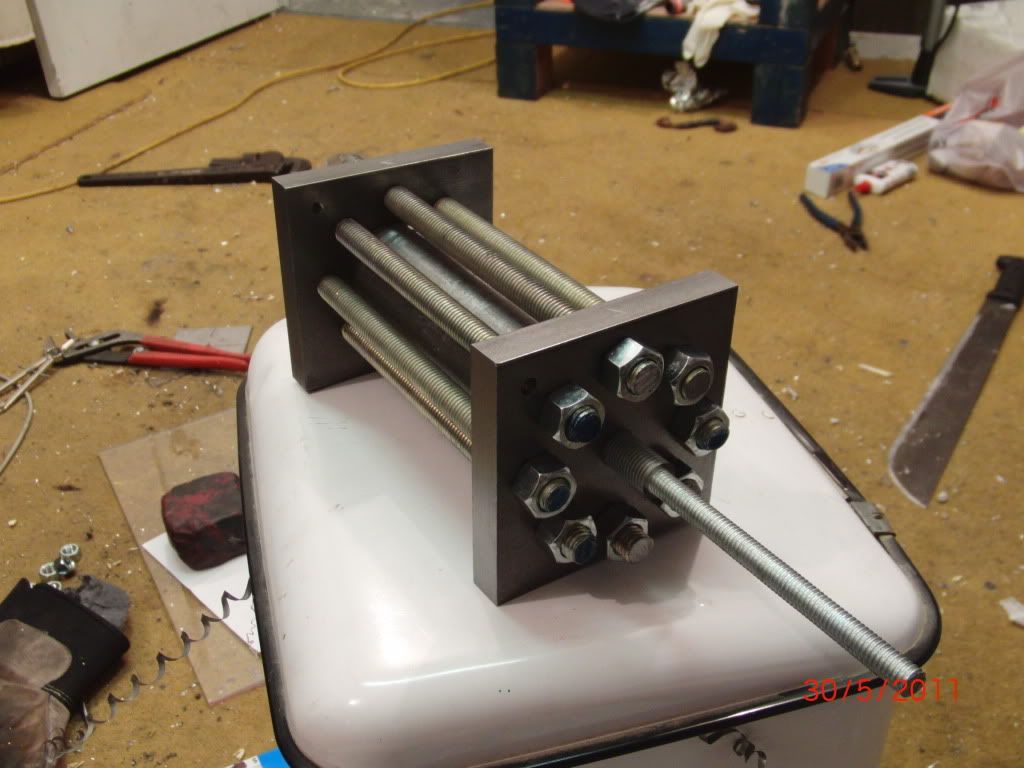

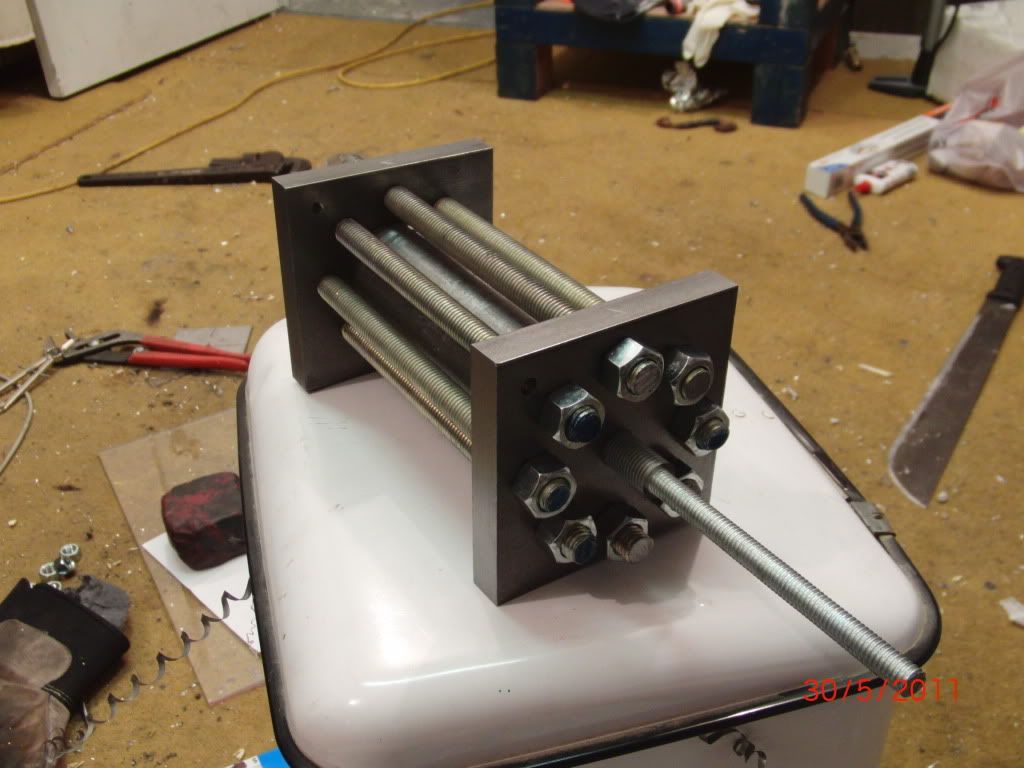

Below are a few pictures of the test device and impact result (the round in the crater is for comparison, as the only remains found of the one launched during the test was a single fragment of less than a cubic millimetre).

Internals of the test device:

Front view:

Rear view (that's an electrode sticking out the back):

Impact area comparison photo:

Using this in an airsoft game may require a minimum engagement distance...

The insulator is so well confined in this new design that there was no change in chamber volume, not even the slightest gas leakage, and no noticeable insulator damage at all after being exposed to gas at ~6000K and 100kpsi, apart from the expected ablation, melting, and subsequent collapse of the inner wall. The only factor discouraging reuse of the insulator is the deformation required during the assembly process to achieve the seal and the aforementioned ablation which is, of course, completely unavoidable without moving to ceramics.

I aim to machine two more insulators and conduct at least one more test today, against an aluminum target instead of the plasticine block (I feared that if the reaction had turned out to be totally useless there would be no damage at all to the aluminum target and thus nothing to judge velocity by). The ejection of a significant quantity of unburned fuel in last night's test points up the need for a stronger rupture diaphragm when using lightweight rounds (no such behavior was detected when testing with a heavy round on the last break from school), and somewhat obscures the results of the impact.

Below are a few pictures of the test device and impact result (the round in the crater is for comparison, as the only remains found of the one launched during the test was a single fragment of less than a cubic millimetre).

Internals of the test device:

Front view:

Rear view (that's an electrode sticking out the back):

Impact area comparison photo:

Using this in an airsoft game may require a minimum engagement distance...

Last edited by DYI on Sat Jun 04, 2011 7:16 am, edited 1 time in total.

Spudfiles' resident expert on all things that sail through the air at improbable speeds, trailing an incandescent wake of ionized air, dissociated polymers and metal oxides.