Figured I'd delay my comment until I had something useful to add...

Here is an idea I came up with during a boredom session at work. I'm not sure if it presents any advantages in terms of reliability, but it may eliminate all switching losses and remove the presence of aluminum oxide.

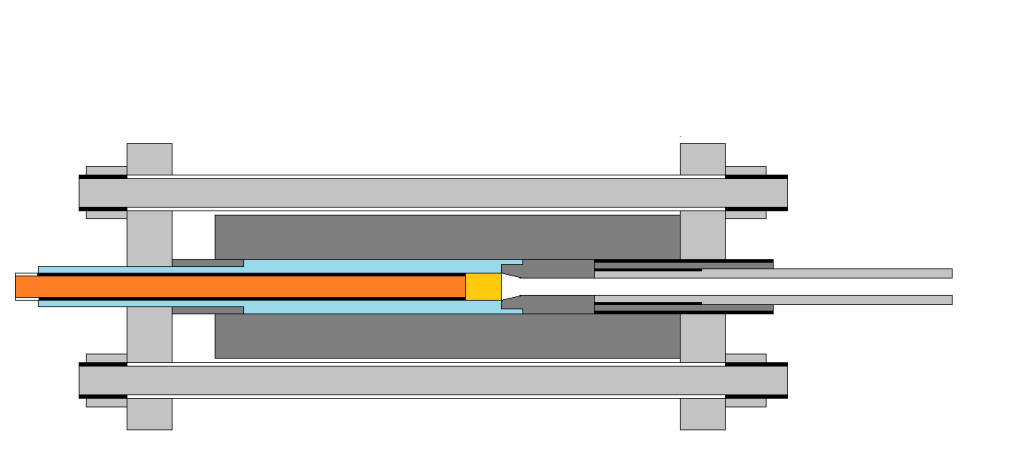

Let me clarify; this is an example diagram, not a finished product. Mechanical issues have not been thought through heavily.

The principle is to use a light gas like hydrogen or helium at extreme pressures to create an insulating boundary where the electrode extends into the chamber, eliminating the need for a mechanical switch.

When the appropriate pressure has been reached, the capacitor bank can be charged. After this has been accomplished, the pressure is raised again until the burst disk ruptures, allowing the gas to evacuate itself from the barrel. The projectile is slightly oversized for the barrel and detent, and thus is unaffected by the pressure drop.

As you will note in the diagram detail, the detent ring allows gas to leak past the projectile slowly because of the imperfect seal. When the gas pressure drops sufficiently, the dielectric breakdown strength will be exceeded and the capacitor bank will discharge through the remaining gas. As the projectile moves forward, the detent leak will be bypassed and the seal will be perfect again.

Notes:

-In practice this should all happen quite quickly due to the low volumes involved.

-There is no traditional "working fluid" or chemical reaction in this design, although it could be adapted to make use of one.

Oh and DYI, nice pictures. I think I quite enjoyed them