al-xg wrote:Poor man's electro-erosion eh ?

I reckon I'd be pretty difficult to rifle the wax inside the barrel without breaking it up especially with large numbers of grooves.

Is there not some sort of lacquer one could use for the same effect ?

I've had good results with nail polish...

Mmm and if you've made a rifling tool for wax why not use it directly on the barrel, scratches would be just as effective as shallow rifling, no ?

They need to be fairly deep scratches to be effective...

Does this maybe allow for etching much harder metals too ?

That's the idea.

why do you need a rifled barrel?

More of a "because I can" than "because I need" exercise

instead of cutting the rifling pattern in wax, how a bout you coat the inside of the barrel with something like this then you print your rifling pattern onto a transparency

Sounds a little

too complex...

I don't think this will work very well at all. Coating the surface of the metal with wax will not prevent an acid solution from attacking the underlying material.

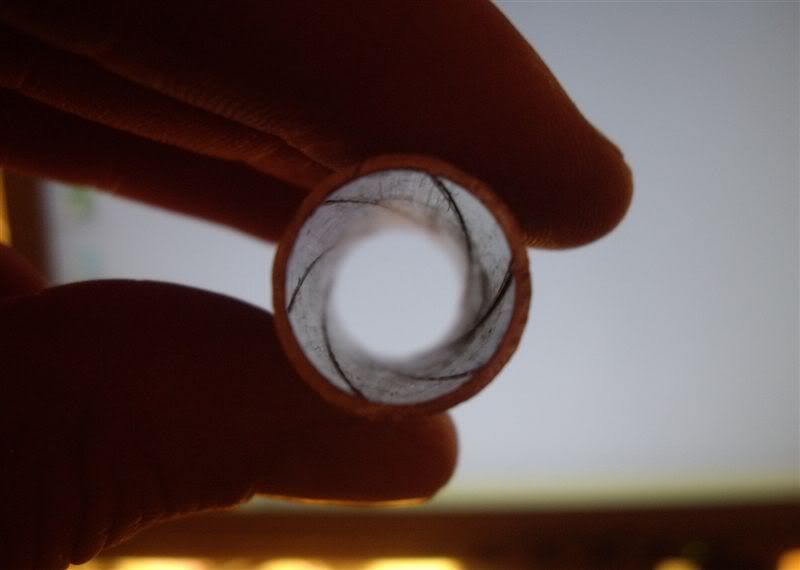

I got some good results with just masking tape

here.

JSR could you modify the thread cutting attachment on your lathe to get an incredibly low threads per inch? This could either work for directly boring a rifles or turning grooves into the wax.

Interesting thought - LeMaudit had written a calculator for it, would be interesting to look into.