Semi-auto blowback WIP

- wyz2285

- First Sergeant 2

- Posts: 2388

- Joined: Sat Mar 06, 2010 7:50 am

- Location: Porto, Portugal

- Has thanked: 1 time

- Been thanked: 4 times

- Contact:

I wanted t know if it's possible to use a hammer valve to archive by having the air re-cocking the hammer while firing a airsoft bb.

I studied some airsoft GBB guns, most of them follows the design of WA magna system

It's a simple system, but a large portion of the propellant is wasted. So I went for a different approach with a design that was attempted by numerous people but I haven't found one that made it work yet. Theory it's simple, having a hammer hit the valve opening it, the air fires the projectile while also pushes back the hammer, re-cocking it. In this design the air that's used to re-cock the hammer ends up exiting from the barrel as well so in theoretically no wast also easier to suppress. It's simpler for me to make the trigger but require a much more precise valve and hammer, also the pressure inside the chamber and various springs with correct length and strength.

I did several GGDT simulation to get an idea of hammer weight, travel distance (which also gives me the volume of air I needed to re-cock the hammer), hammer force (spring strength, weak enough for the air to push it, yet strong enough to open the valve to give the correct amount of air) and most important , barrel pressure. Then all left to do it's find the balance between force needed to open the valve, hammer strength and result barrel pressure.

In the worst case, considering dead volume as hammer travel*area, using a .2g 6mm bb (actually varies from 5.99 to 5.98 mm), 6.1mm barrel, the barrel pressure it's 1.6 bar, hope with a hop up (airtight detente) I may get a little more. So far with 1.6 bar should be enough.

For now I have finished all the tricky parts: trigger, valve and airtight hammer with spring.

I studied some airsoft GBB guns, most of them follows the design of WA magna system

It's a simple system, but a large portion of the propellant is wasted. So I went for a different approach with a design that was attempted by numerous people but I haven't found one that made it work yet. Theory it's simple, having a hammer hit the valve opening it, the air fires the projectile while also pushes back the hammer, re-cocking it. In this design the air that's used to re-cock the hammer ends up exiting from the barrel as well so in theoretically no wast also easier to suppress. It's simpler for me to make the trigger but require a much more precise valve and hammer, also the pressure inside the chamber and various springs with correct length and strength.

I did several GGDT simulation to get an idea of hammer weight, travel distance (which also gives me the volume of air I needed to re-cock the hammer), hammer force (spring strength, weak enough for the air to push it, yet strong enough to open the valve to give the correct amount of air) and most important , barrel pressure. Then all left to do it's find the balance between force needed to open the valve, hammer strength and result barrel pressure.

In the worst case, considering dead volume as hammer travel*area, using a .2g 6mm bb (actually varies from 5.99 to 5.98 mm), 6.1mm barrel, the barrel pressure it's 1.6 bar, hope with a hop up (airtight detente) I may get a little more. So far with 1.6 bar should be enough.

For now I have finished all the tricky parts: trigger, valve and airtight hammer with spring.

CpTn_lAw wrote:"yay, me wanna make big multishot pnoob with 1000 psi foot pump compressor using diamond as main material. Do you think wet bread make good sealant? "

- Gun Freak

- Lieutenant 5

- Posts: 4971

- Joined: Mon Jan 25, 2010 4:38 pm

- Location: Florida

- Been thanked: 8 times

Looking great at this point, not much else to say... Hope it works!!

OG Anti-Hybrid

One man's trash is a true Spudder's treasure!

Golf Ball Cannon "Superna" ■ M16 BBMG ■ Pengun ■ Hammer Valve Airsoft Sniper ■ High Pressure .22 Coax

Holy Shat!

One man's trash is a true Spudder's treasure!

Golf Ball Cannon "Superna" ■ M16 BBMG ■ Pengun ■ Hammer Valve Airsoft Sniper ■ High Pressure .22 Coax

Holy Shat!

Looking promising!, the whole thing looks impressively made.

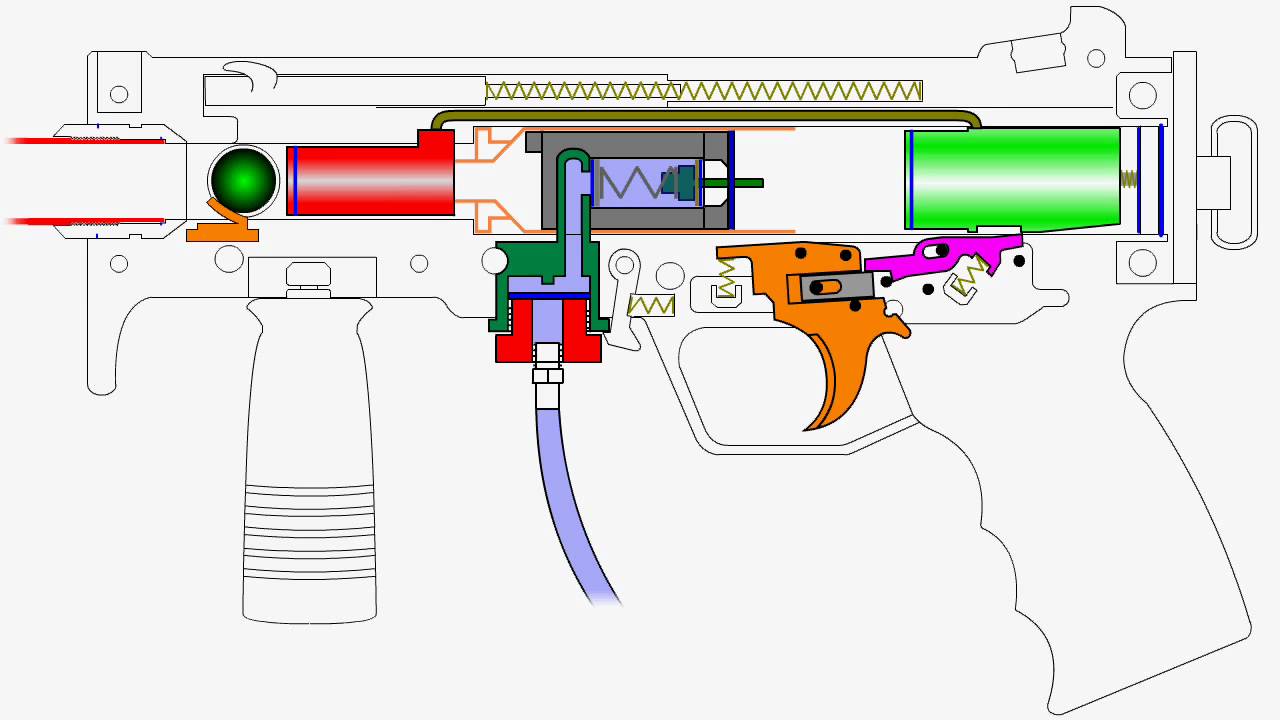

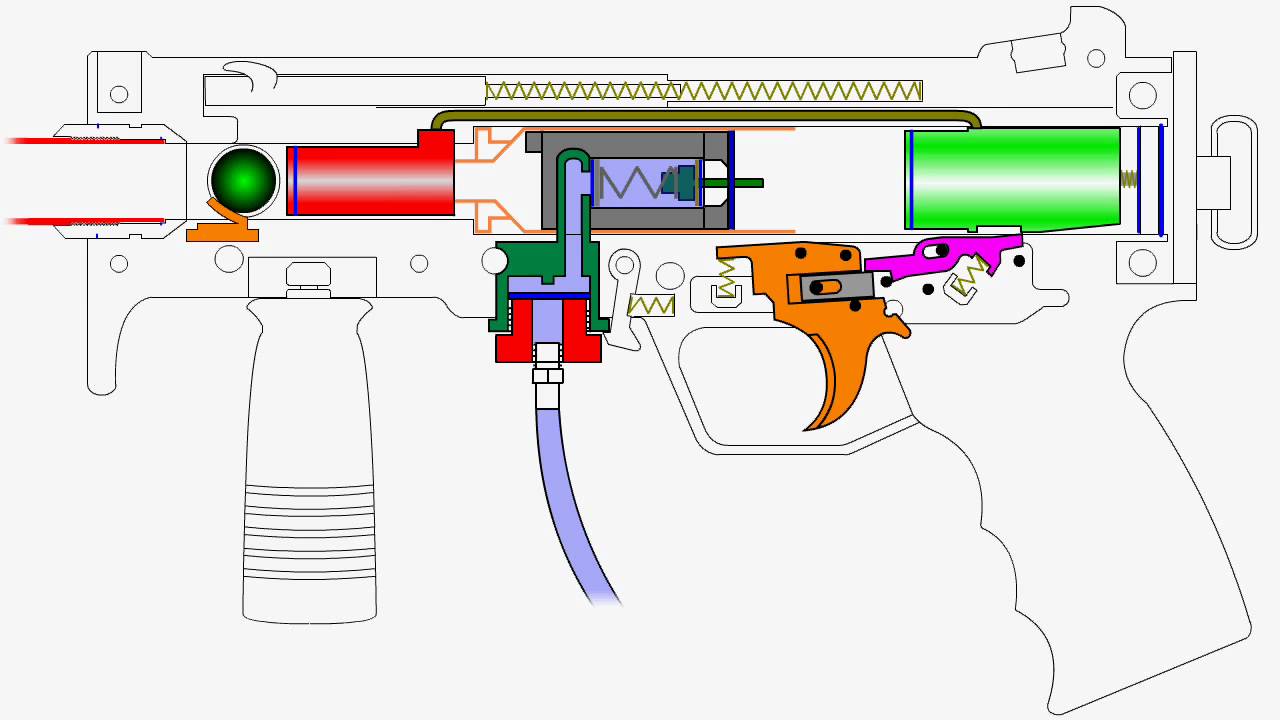

Am I correct in guessing your going for a layout similar to what you find in tippmann paintball guns, what with a centrally located valve, hammer hits valve, hammer pushed back,gas flows around the inline valve unit, etc?

something like this:

Am I correct in guessing your going for a layout similar to what you find in tippmann paintball guns, what with a centrally located valve, hammer hits valve, hammer pushed back,gas flows around the inline valve unit, etc?

something like this:

Something to bear in mind is if your striker is sealed so it works as a piston, as it travels forward to strike the valve, air in front of it will be compressed, slowing the striker.

I'd favour a gas piston affair like AKs, that allows for more force to return the striker. It also means that you're not losing gas from where it's most needed, instead you're just tapping it from forward on the barrel.

I'd favour a gas piston affair like AKs, that allows for more force to return the striker. It also means that you're not losing gas from where it's most needed, instead you're just tapping it from forward on the barrel.

/sarcasm, /hyperbole

- wyz2285

- First Sergeant 2

- Posts: 2388

- Joined: Sat Mar 06, 2010 7:50 am

- Location: Porto, Portugal

- Has thanked: 1 time

- Been thanked: 4 times

- Contact:

Same here, the air in front of the striker can exit from the valve to barrel. How can a design like the AK allow more force to re-cock the striker?

CpTn_lAw wrote:"yay, me wanna make big multishot pnoob with 1000 psi foot pump compressor using diamond as main material. Do you think wet bread make good sealant? "

- Gun Freak

- Lieutenant 5

- Posts: 4971

- Joined: Mon Jan 25, 2010 4:38 pm

- Location: Florida

- Been thanked: 8 times

No because it would have to be sealed when when its moving backward due to the pressure but that same seal direction makes it compress air when the trigger is pulled. Like wyz said it will be directed out the barrel anyway, so it's theoretically just added power.Lazyboy wrote:Could the seal on the striker be designed like that in a bike pump, i.e seals in one direction only?

This looks really good I will follow with interest

OG Anti-Hybrid

One man's trash is a true Spudder's treasure!

Golf Ball Cannon "Superna" ■ M16 BBMG ■ Pengun ■ Hammer Valve Airsoft Sniper ■ High Pressure .22 Coax

Holy Shat!

One man's trash is a true Spudder's treasure!

Golf Ball Cannon "Superna" ■ M16 BBMG ■ Pengun ■ Hammer Valve Airsoft Sniper ■ High Pressure .22 Coax

Holy Shat!

- wyz2285

- First Sergeant 2

- Posts: 2388

- Joined: Sat Mar 06, 2010 7:50 am

- Location: Porto, Portugal

- Has thanked: 1 time

- Been thanked: 4 times

- Contact:

Theoretically it works, realistically it doesn't.

I putted the parts together, the hammer doesn't even move after the valve has opened.

Going to try a different way, sacrificing power in return of semi-auto... I'm really sad to not be able to archive something what even the cheapest airsoft pistol can do.

I putted the parts together, the hammer doesn't even move after the valve has opened.

Going to try a different way, sacrificing power in return of semi-auto... I'm really sad to not be able to archive something what even the cheapest airsoft pistol can do.

CpTn_lAw wrote:"yay, me wanna make big multishot pnoob with 1000 psi foot pump compressor using diamond as main material. Do you think wet bread make good sealant? "

- wyz2285

- First Sergeant 2

- Posts: 2388

- Joined: Sat Mar 06, 2010 7:50 am

- Location: Porto, Portugal

- Has thanked: 1 time

- Been thanked: 4 times

- Contact:

made this work, wonderfully.

Works the same way as what Gun Freak and JSR posted, but I had it in my mind for a while also.

My spring box haven't arrived, but thanks to the o-rings I bought I could make the all the little spots airtight.

Only tested it by push a blowgun nozzle against the port that will be connected to the hammer valve, with quite a strong spring pushing the piston, it still delivers a hard kick and the flow isn't bad at all.

Designed a new rotating hammer for it, going to mill it out tomorrow, hopefully next week I'll be able to post the gun

Works the same way as what Gun Freak and JSR posted, but I had it in my mind for a while also.

My spring box haven't arrived, but thanks to the o-rings I bought I could make the all the little spots airtight.

Only tested it by push a blowgun nozzle against the port that will be connected to the hammer valve, with quite a strong spring pushing the piston, it still delivers a hard kick and the flow isn't bad at all.

Designed a new rotating hammer for it, going to mill it out tomorrow, hopefully next week I'll be able to post the gun

CpTn_lAw wrote:"yay, me wanna make big multishot pnoob with 1000 psi foot pump compressor using diamond as main material. Do you think wet bread make good sealant? "

- wyz2285

- First Sergeant 2

- Posts: 2388

- Joined: Sat Mar 06, 2010 7:50 am

- Location: Porto, Portugal

- Has thanked: 1 time

- Been thanked: 4 times

- Contact:

Finished the valve, I machined it from a solid aluminium cylinder

The valve stem is probably the most tricky thing I've made so far but with the help of some homemade HSS tools it turned out really well

but with the help of some homemade HSS tools it turned out really well

I'll finished milling the hammer this afternoon and start assemble tomorrow.

The valve stem is probably the most tricky thing I've made so far

I'll finished milling the hammer this afternoon and start assemble tomorrow.

CpTn_lAw wrote:"yay, me wanna make big multishot pnoob with 1000 psi foot pump compressor using diamond as main material. Do you think wet bread make good sealant? "

- Gun Freak

- Lieutenant 5

- Posts: 4971

- Joined: Mon Jan 25, 2010 4:38 pm

- Location: Florida

- Been thanked: 8 times

Getting a lathe/mill is the best thing that's ever happened to you

OG Anti-Hybrid

One man's trash is a true Spudder's treasure!

Golf Ball Cannon "Superna" ■ M16 BBMG ■ Pengun ■ Hammer Valve Airsoft Sniper ■ High Pressure .22 Coax

Holy Shat!

One man's trash is a true Spudder's treasure!

Golf Ball Cannon "Superna" ■ M16 BBMG ■ Pengun ■ Hammer Valve Airsoft Sniper ■ High Pressure .22 Coax

Holy Shat!

- wyz2285

- First Sergeant 2

- Posts: 2388

- Joined: Sat Mar 06, 2010 7:50 am

- Location: Porto, Portugal

- Has thanked: 1 time

- Been thanked: 4 times

- Contact:

Epoxyed the valve with blow-back cylinder, hammer locking mechanism finished, roughly shaped the hammer which already works

All left are actually just some holes to drill and mount everything

All left are actually just some holes to drill and mount everything

- Attachments

CpTn_lAw wrote:"yay, me wanna make big multishot pnoob with 1000 psi foot pump compressor using diamond as main material. Do you think wet bread make good sealant? "

- jakethebeast

- Corporal 5

- Posts: 945

- Joined: Sat Jul 03, 2010 4:20 pm

- Location: Jakes cave

Looks pretty damn good wyz!

Est Sularus Oth Mithas

- wyz2285

- First Sergeant 2

- Posts: 2388

- Joined: Sat Mar 06, 2010 7:50 am

- Location: Porto, Portugal

- Has thanked: 1 time

- Been thanked: 4 times

- Contact:

Finished the housing, now just missing some holes to mount the pieces of trigger and hammer

Edit: made some adjustments on the piston length, burst the power a little Also will favor the return spring life span.

Also will favor the return spring life span.

Edit: made some adjustments on the piston length, burst the power a little

- Attachments

CpTn_lAw wrote:"yay, me wanna make big multishot pnoob with 1000 psi foot pump compressor using diamond as main material. Do you think wet bread make good sealant? "

- wyz2285

- First Sergeant 2

- Posts: 2388

- Joined: Sat Mar 06, 2010 7:50 am

- Location: Porto, Portugal

- Has thanked: 1 time

- Been thanked: 4 times

- Contact:

Finished the hammer and lock.

Tested, worked at pressure as low as 50 psi. past through 100 psi the piston opens as a bang also travels back way further than I thought. Hammer is re-cocked reliably, however I'll take the advantage of the extra piston travel to use a weak spring but longer for a smoother operation.

Tested, worked at pressure as low as 50 psi. past through 100 psi the piston opens as a bang also travels back way further than I thought. Hammer is re-cocked reliably, however I'll take the advantage of the extra piston travel to use a weak spring but longer for a smoother operation.

CpTn_lAw wrote:"yay, me wanna make big multishot pnoob with 1000 psi foot pump compressor using diamond as main material. Do you think wet bread make good sealant? "