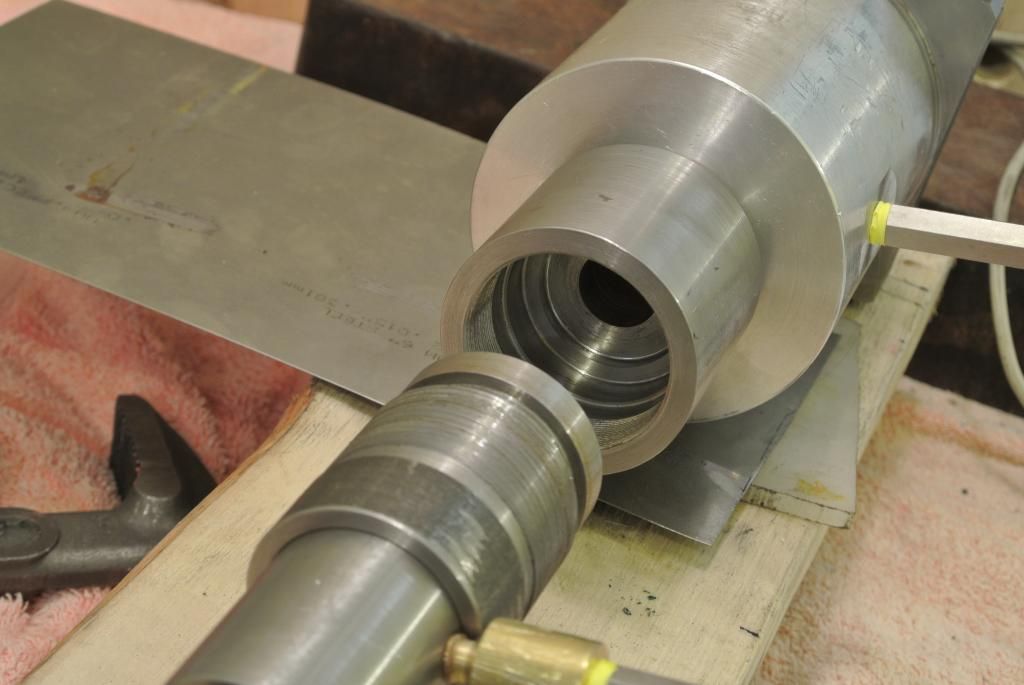

Chamber: 1.525" ID x 3.5" long, 1.5" long taper from 1.525" to 0.800". 2024-T651 aluminum with 1" thick walls (this is a chamber I made about 3 years ago which was a convenient fit for the project)

Barrel: 0.760" ID x 85" long. 1" OD DOM tube.

Operating pressure: up to 12000psi.

Fuel mix: oxygen/hydrogen only. Pre-ignition pressure up to 1750psi. First shot used 90:10 hydrogen/oxygen at a pre-ignition pressure of 1714psi.

Fuel meter: 2 inlets, for unregulated hydrogen and oxygen, both with 10000psi needle valves. Gauge is 0-3000psi, +/-0.25% over full range. Connection to the chamber is also a needle valve. Currently uses 3000psi unions for disassembly. All hoses are PTFE lined and rated for oxygen service to 3000psi.

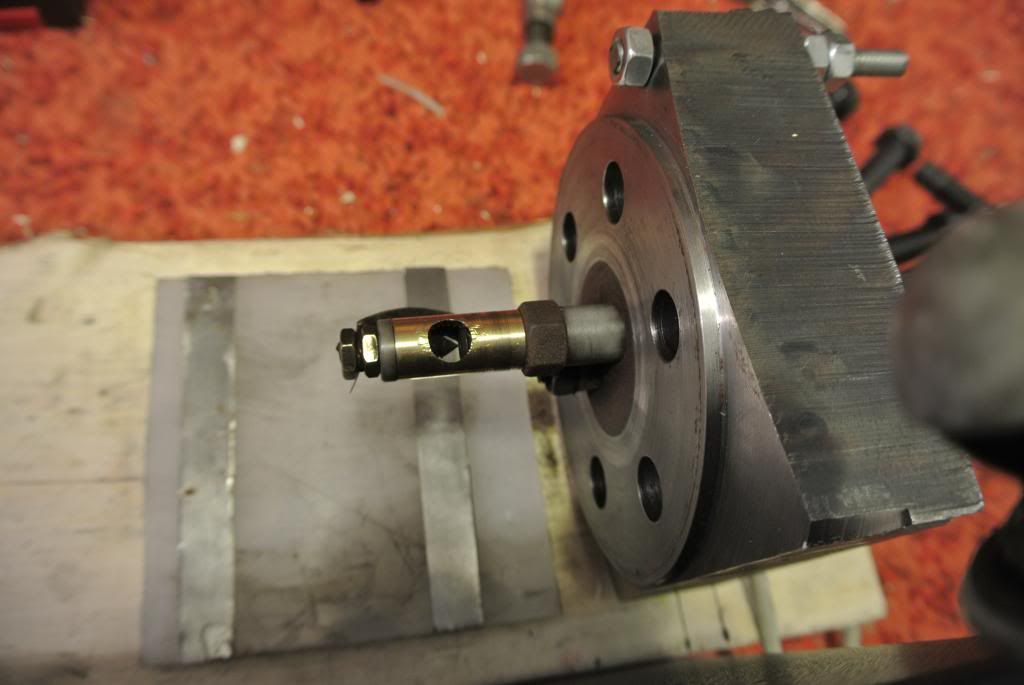

Ignition: finely adjustable spark gap mounted on machined high pressure pass through. HV supply is a standard battery operated barbecue igniter. Note that the version pictured here is last year's, and has been slightly improved since, but is functionally identical.

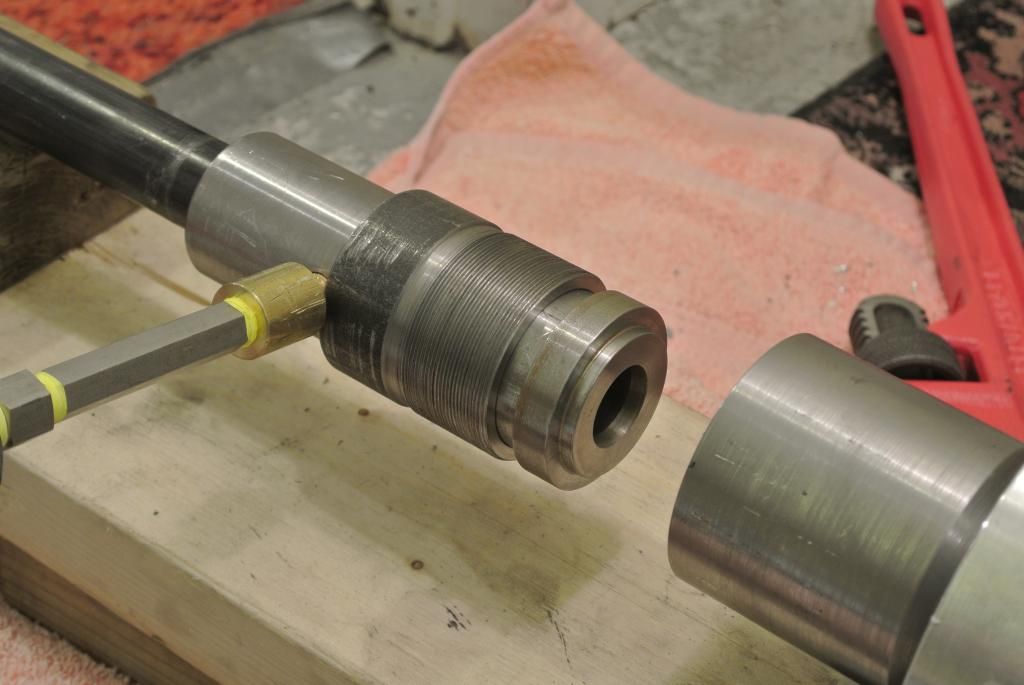

Breech: 3-part design allowing the disc or shear skirt to be clamped without rotation. For harder skirt or disc materials, 0.03" thick machined Delrin gaskets are used. The breech can accommodate assemblies up to 0.155" thick, and has a short tapered region immediately downstream of the disc or skirt to prevent the torn edges from obstructing the flow.

Projectiles: shear skirt design (can also take burst disks). I've used these before, but haven't posted them. The 7075-T6 aluminum slug shown is drag stabilized by way of a drilled out tail, and its shear skirt is designed to release at 9000psi.

Performance: predicted at 1110m/s with a 14.4g projectile, using the GALE code with empirical calibrations. Although I attempted to chrono the first shot, the Chrony was blinded by the flash, for reasons that will become apparent when you watch the video. The breakwire device I mentioned a few years ago is still in the works, due to a major difference of opinions between its designer and Customs.

Of particular note here is the fact that this appears to be the first hybrid on Spudfiles using an oxygen/hydrogen mix. Also of note is the (still terrifying) unregulated gas supply, the high pressure breech connection which allows the barrel to be evacuated or purged with hydrogen, and the fact that I'm igniting a mix at 1700psi precharge using a $20 barbecue sparker.

For the first (and currently only) shot, the spark gap was near the center of the chamber, and set to a width of 0.003". The mix ignited immediately upon pressing the igniter button. The projectile for the first shot had a mass of 14.4g, of which 7.67g was recovered after the shot. Due to a leak elsewhere in the vacuum system, the original plan to pull a vacuum on the barrel was scrapped in favor of simply purging it with hydrogen, which is nearly as good in terms of performance gains (about 10% over an air filled barrel, at this speed).

This is in the discussion and not the showcase for a reason: it is very much a work in progress, and there are still a lot of kinks to be ironed out of the system before it can be considered fully operational. The central functions, however, appear to work properly. The name stems from the fact that this launcher is both the first stage of my CLGG development program, and the first stage of my upcoming 2-stage light gas gun design. It is also my first major step back into the hybrid world after the 2008 mishap.

Finally, the video: Here it is

The violet-white flash 4 frames after the first appearance of the muzzle flash is the projectile hitting the target. The range from muzzle to target is 3.5m, and the frame rate is 1200 frames/s. Accounting for drag, the projected muzzle speed of 1100m/s is near the center of the possible range given by the video.