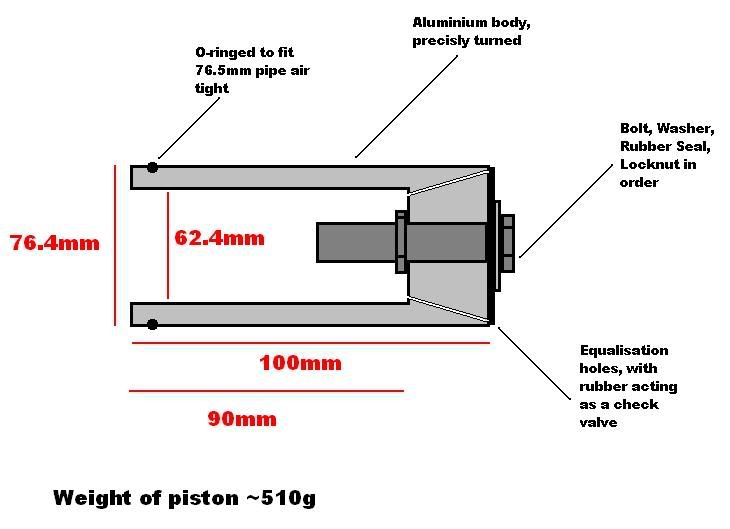

This is what the piston will look like, with a built in check valve and the pilot are being totally air tight I should have no back flow, I have decided to drill the middle out to reduce weight but this also increases the volume of air to be vented but I thought it would be a good trade off.

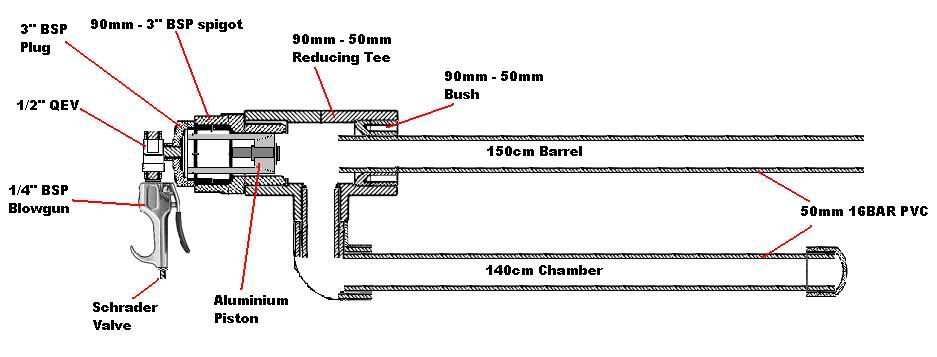

And this is the design of it, Im probly going to go with the 50mm chamber to save money and depending on how much money I get may put the chamber closer to the barrel with 2 45* elbows.

With the sealing face being right far forward I hope to in crease flow to about 50% maybe.

The C:B ratio should be about 1:1 including the area in the elbow and piston area.

I was thinking I could fill the piston with expanding foam to reduce the pilot volume, think that would work?

Tell me what you think, and Im open to suggestions becuase nows the time to change the design.