Show us your pneumatic spud gun! Discuss pneumatic (compressed gas) powered potato guns and related accessories. Valve types, actuation, pipe, materials, fittings, compressors, safety, gas choices, and more.

-

A-98

- Corporal 5

- Posts: 921

- Joined: Thu Apr 27, 2006 7:41 pm

- Location: Santa Barbara, CA

Fri Mar 30, 2007 12:33 am

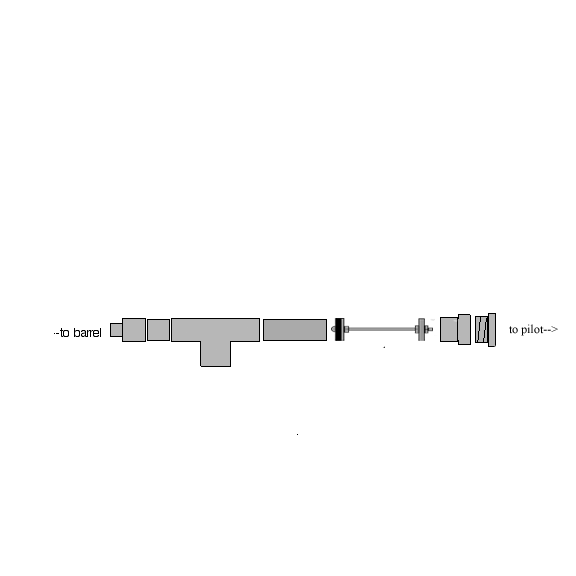

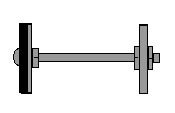

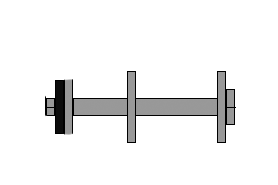

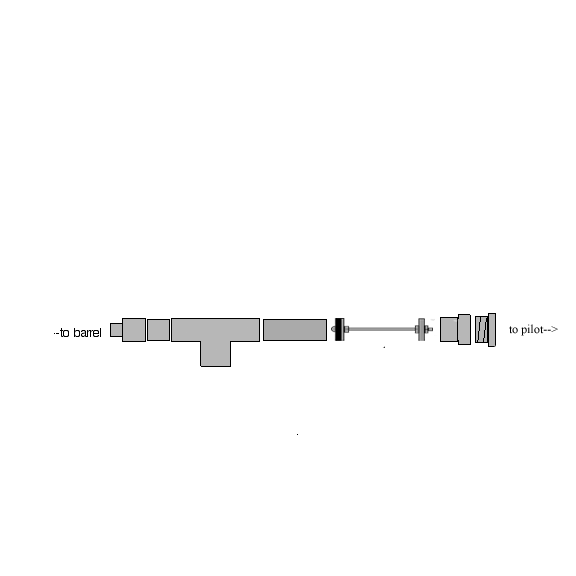

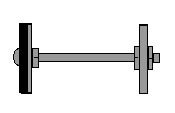

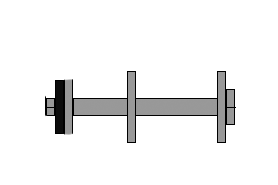

ok, ive designed this a copper cannon, but seeing as this will be my first piston gun i would like some input. ive uploaded the images for the layout of the valve, and the layout of my two piston designs(the second one was a bit rushed)

any suggestions would be appreciated, and thanks to BLB for helping out already.

There are rules, and then there are hundred dollar bills.

-

A-98

- Corporal 5

- Posts: 921

- Joined: Thu Apr 27, 2006 7:41 pm

- Location: Santa Barbara, CA

Fri Mar 30, 2007 10:09 am

anyone?

There are rules, and then there are hundred dollar bills.

-

joannaardway

- Corporal 5

- Posts: 949

- Joined: Mon Oct 09, 2006 4:57 pm

- Location: SW Hertfordshire, England, UK.

Fri Mar 30, 2007 12:24 pm

Damn you - I've been sigged!

It could work - it depends on exactly where your sealing face is though.

I'll talk to my brother about advanced piston designs - he's somewhat of a guru when it comes to small piston valves (he's built 8 valves around this size)

Novacastrian: How about use whatever the heck you can get your hands on?

frankrede: Well then I guess it won't matter when you decide to drink bleach because your out of kool-aid.

...I'm sorry, but that made my year.

-

A-98

- Corporal 5

- Posts: 921

- Joined: Thu Apr 27, 2006 7:41 pm

- Location: Santa Barbara, CA

Fri Mar 30, 2007 3:57 pm

wow, does he have aim or something. it might be easier. if he does you could PM it to me for privacy. if he doesnt, feel free to leave a comment here.

and it would be nice for a relatively speedy reply due to the fat that i will be leaving monday and gone for a week. so i would like to build it this weekend.

Thanks,

Bryce.

There are rules, and then there are hundred dollar bills.

-

Hawkeye

- Specialist 4

- Posts: 462

- Joined: Sun Jan 21, 2007 7:12 pm

Fri Mar 30, 2007 4:45 pm

I would use a smaller T or reduce the piston section down to 3/4 copper for the sole reason that 5/8 tap washers are a virtually perfect fit inside 3/4 inch copper. Then you can just stack four washers and a neoprene face together for the piston.

Presumably you have it set up with metal washers which aren't the best sliding surface on copper.

You can also set up a more complicated stacked washer piston with an o-ring one way seal, but start with a simple one first. Just cut a thin groove down the side for air to leak past and fill the chamber.

-

A-98

- Corporal 5

- Posts: 921

- Joined: Thu Apr 27, 2006 7:41 pm

- Location: Santa Barbara, CA

Fri Mar 30, 2007 5:50 pm

yes, im planning to make one simple piston, and get the supplies for more and more complicated pistons. i think i will make 2 pistons first, and then thru trial and error improve them. i hope to succesfully make one that uses BTB's design that reduces/eliminates backflow.

There are rules, and then there are hundred dollar bills.

-

A-98

- Corporal 5

- Posts: 921

- Joined: Thu Apr 27, 2006 7:41 pm

- Location: Santa Barbara, CA

Fri Mar 30, 2007 6:20 pm

ya, pretty much.

i think im going to go with the 3/4 valve, or maybe the 1". im going to have a1.5" chamber, and some sort of stock. and ill hopefully find some ball bearings that will fit a 1/2" copper barrel with minumum wadding.

There are rules, and then there are hundred dollar bills.

-

joannaardway

- Corporal 5

- Posts: 949

- Joined: Mon Oct 09, 2006 4:57 pm

- Location: SW Hertfordshire, England, UK.

Sat Mar 31, 2007 9:31 am

Ok, the offical words from my brother are:

-You really need some sort of bumper for that, as pistons come back quite hard.

-The sealing face should be almost at the front of the branch of the tee.

-Any anti-back flow idea is good.

- Your second piston design is better (you really need at least three washers - allegedly), but make it shorter.

He's apparently also working on a new "ultra piston valve" idea, but he's staying quite quiet about that.

If that helps, then good. If not, I'll go kick him for you.

Novacastrian: How about use whatever the heck you can get your hands on?

frankrede: Well then I guess it won't matter when you decide to drink bleach because your out of kool-aid.

...I'm sorry, but that made my year.

-

chaos

- Sergeant 3

- Posts: 1205

- Joined: Wed Jan 17, 2007 8:31 am

Sat Mar 31, 2007 10:56 am

i have used 2 washers and it worked fine

but im working on this really kool new piston as well its one piece done on a lathe.

-

A-98

- Corporal 5

- Posts: 921

- Joined: Thu Apr 27, 2006 7:41 pm

- Location: Santa Barbara, CA

Sat Mar 31, 2007 1:23 pm

joannaardway wrote:Ok, the offical words from my brother are:

-You really need some sort of bumper for that, as pistons come back quite hard.

-The sealing face should be almost at the front of the branch of the tee.

-Any anti-back flow idea is good.

- Your second piston design is better (you really need at least three washers - allegedly), but make it shorter.

He's apparently also working on a new "ultra piston valve" idea, but he's staying quite quiet about that.

If that helps, then good. If not, I'll go kick him for you.

that helped alot, and i forgot to include a bumper in the drawing

.

any input on the specific design of the piston, other than atleast 3 washers, would be greatly appreciated. and any tips on the anti back-flow design would be appreciated.

sorry for any hassles.

There are rules, and then there are hundred dollar bills.

-

c19o

- Specialist 3

- Posts: 356

- Joined: Thu Dec 14, 2006 11:59 pm

- Location: Fairfield Bay, Arkanasas

Sat Mar 31, 2007 1:40 pm

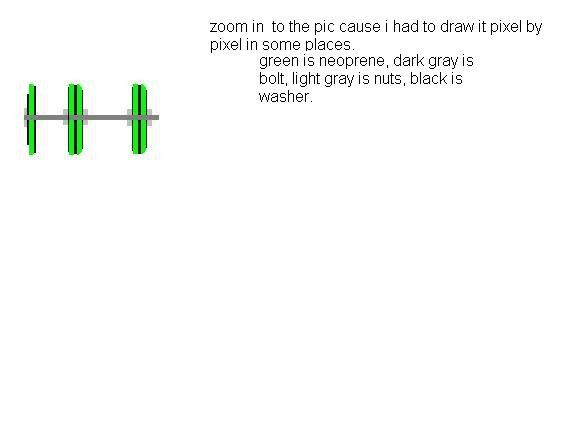

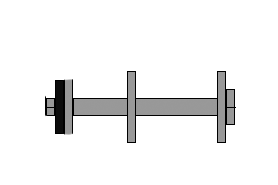

Put up the design I drew for you , A-98. Maybe they can improve it

Edit: Ahh, I'll put it up.

Edit: Ok, heres the design of piston I made for A-98, you have to download the picture and zoom in on it to see it well.

Oops, looks like I forgot the nut behind the washer on the sealing face.

off topic - Would it be safe to make a 600 psi 3/4 porting copper piston valve? Or put 600 psi in 1.5" or 2" galvanized steel pipe? thanks

-

Hawkeye

- Specialist 4

- Posts: 462

- Joined: Sun Jan 21, 2007 7:12 pm

Sat Mar 31, 2007 2:04 pm

You might want to make one that operates at 200-350, shoot it, and then decide if you need to double your psi.

I guess more complicated heavier pistons are preferred judging by the posted diagrams. Not sure why though.

-

c19o

- Specialist 3

- Posts: 356

- Joined: Thu Dec 14, 2006 11:59 pm

- Location: Fairfield Bay, Arkanasas

Sat Mar 31, 2007 2:37 pm

I just want a ridiculously powerful gun, thats all. But I don't know if I should order the pressure rated fittings on mcmaster, or just use the galvanized steel parts at my hardware store.

PM me if instead of posting here, I dont want this topic to be off topic and all the mods be mad at me.

Back on topic: A-98, I'll draw you some more piston designs if you want, we could talk on aim about it too. It would help if I got pictures of your parts too.

-

joannaardway

- Corporal 5

- Posts: 949

- Joined: Mon Oct 09, 2006 4:57 pm

- Location: SW Hertfordshire, England, UK.

Sat Mar 31, 2007 3:12 pm

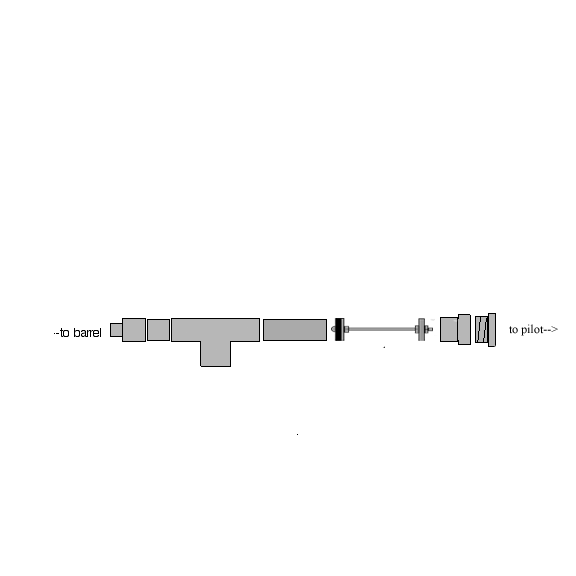

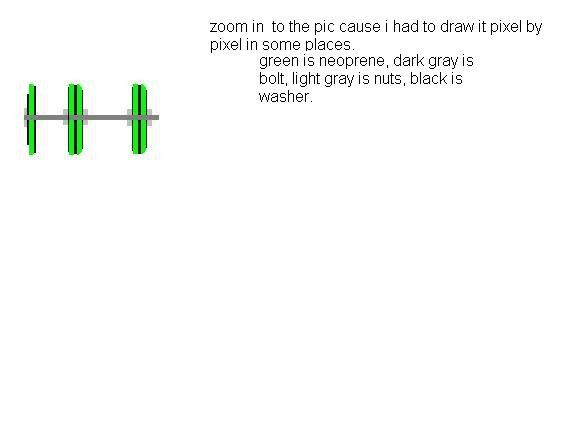

Anti backflow eh?

What you can see

here is the piston my brother currently uses.

The rubber washer on the left of the image acts as a check valve, allowing flow from left to right, but not vice versa.

Novacastrian: How about use whatever the heck you can get your hands on?

frankrede: Well then I guess it won't matter when you decide to drink bleach because your out of kool-aid.

...I'm sorry, but that made my year.