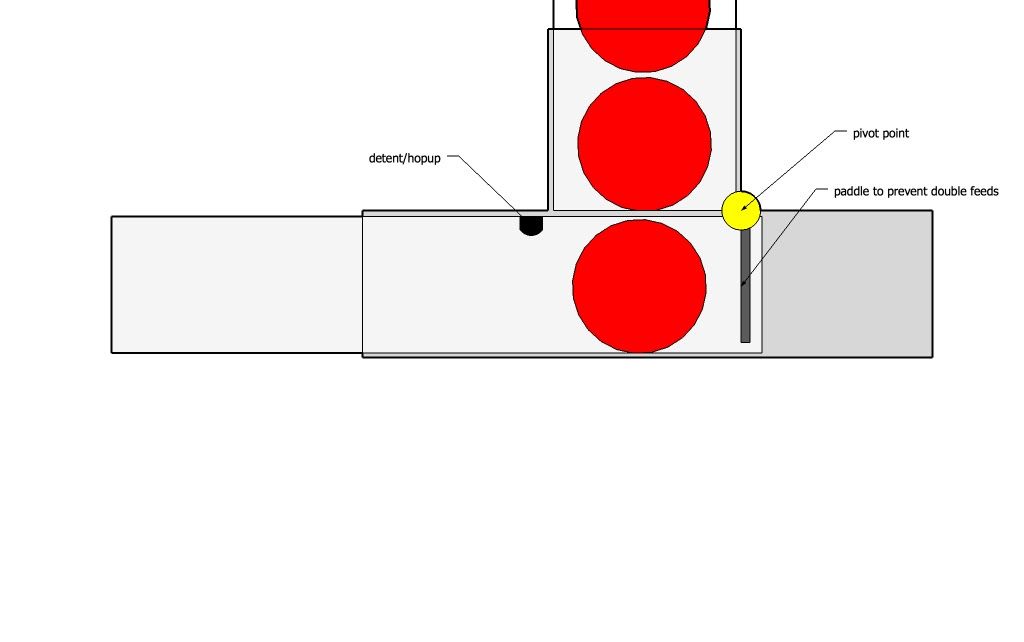

I have been designing and redesigning my upcoming launcher, and I have now abandoned the pneumatic cylinder option. So I decided to go with a blowback design for the loading mech. It seems simple enough, but I'm having some second thoughts about it. I fear that it may chop up paintball randomly, that the spring will have to be adjusted depending on firing pressure, and that the blowback option will decrease the power and efficiency of the launcher.

Now, my expectations for the launcher:

I want it to be fully adjustable, from close range messing around, to field legal speed, to bonecrushing, ass kicking power

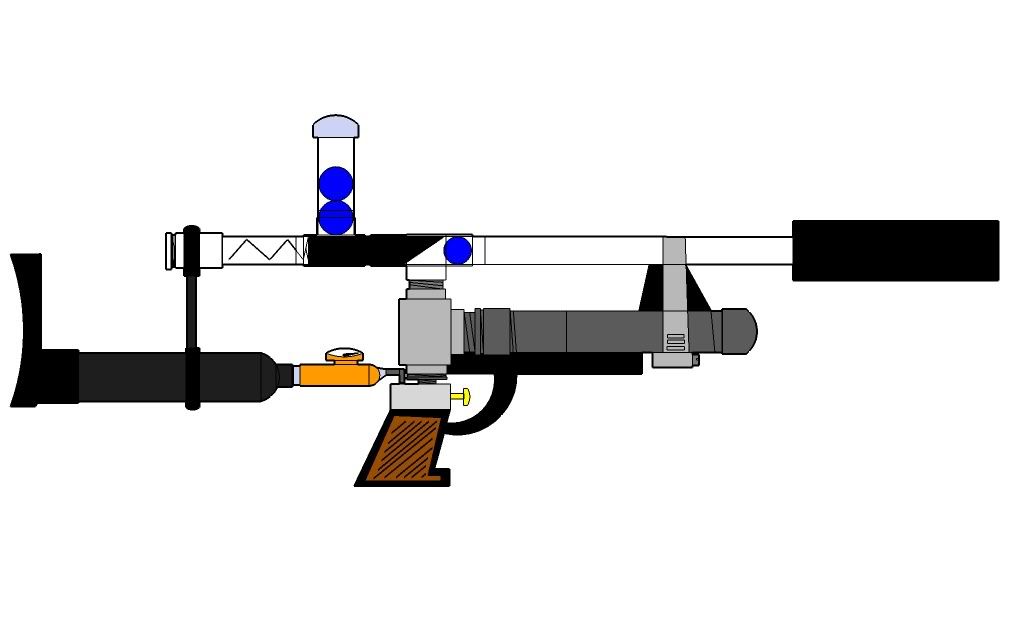

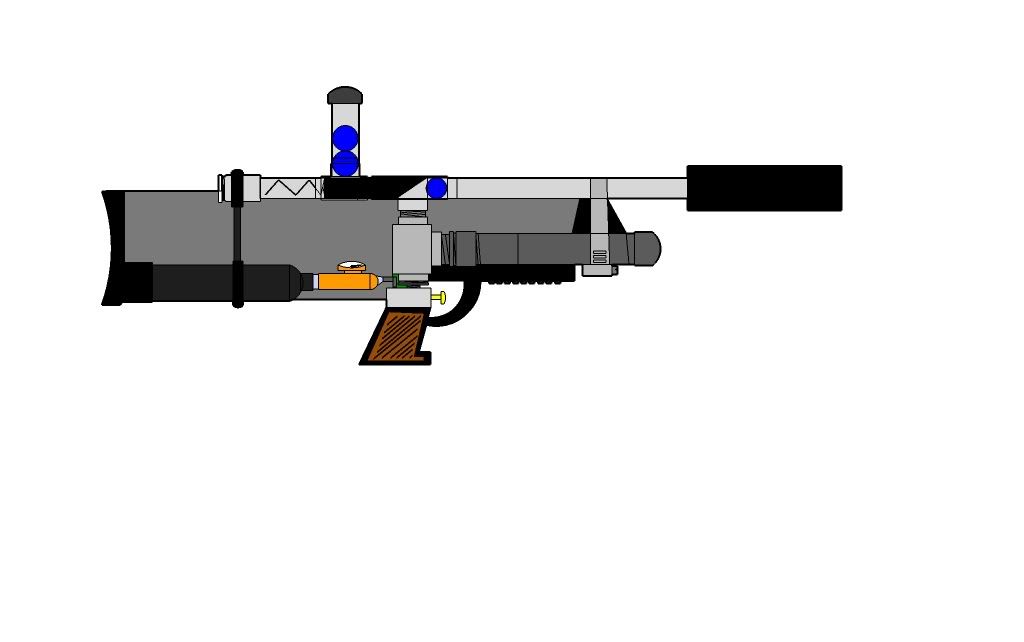

Here is the current design, it was made for functionality, adapted for looks.

The barrel will probably be longer and a real hopper may be added

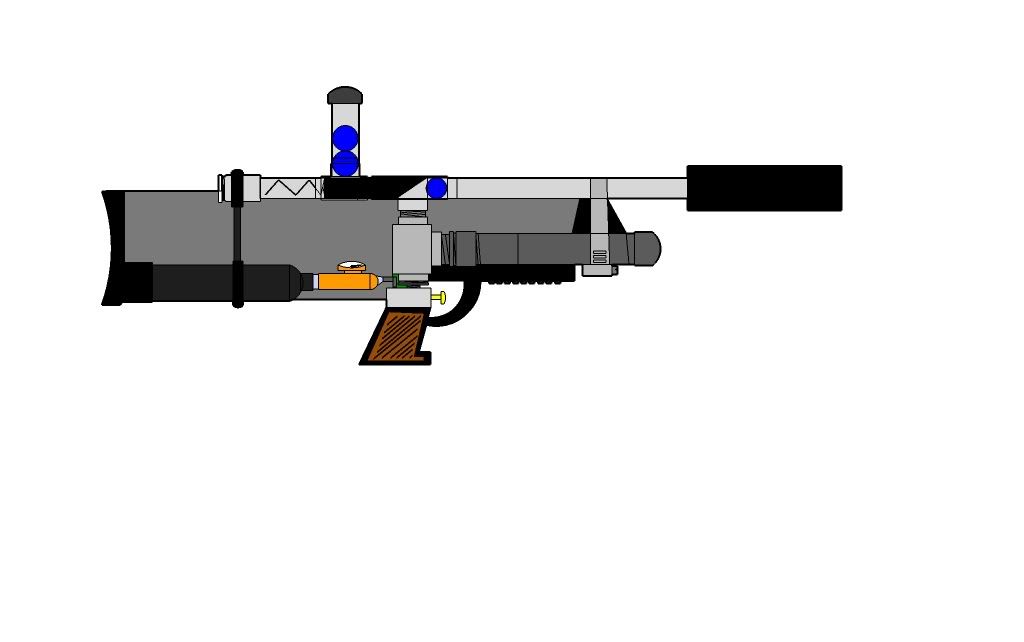

Aluminum flashing will be made into a body:

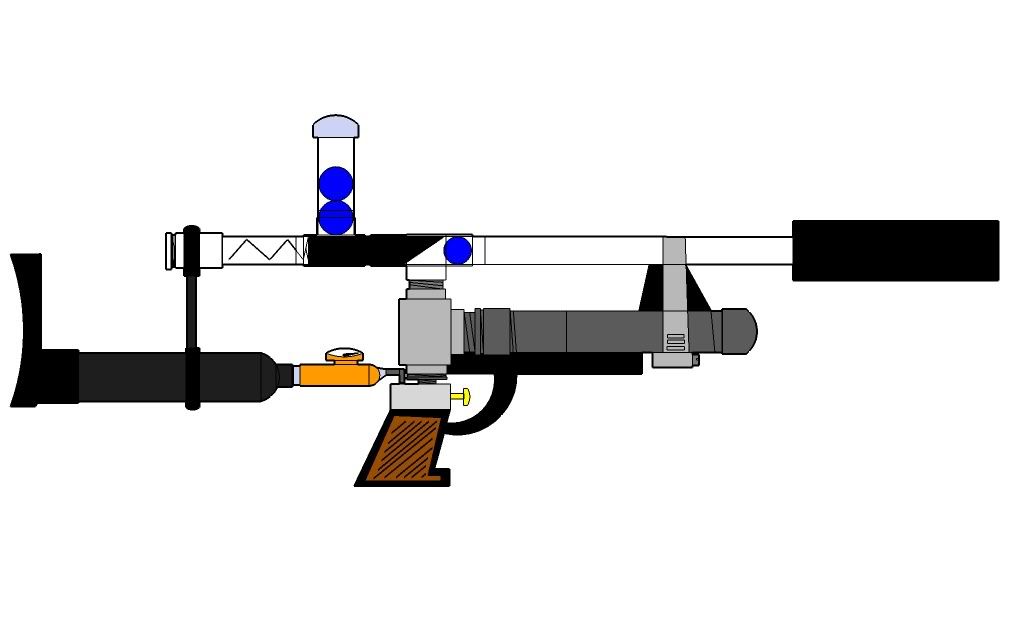

eventually, I hope to have this

Comments, thoughts, critique, and improvements